Introduction to Fibre-Optical Module PCB

Overview and Definition

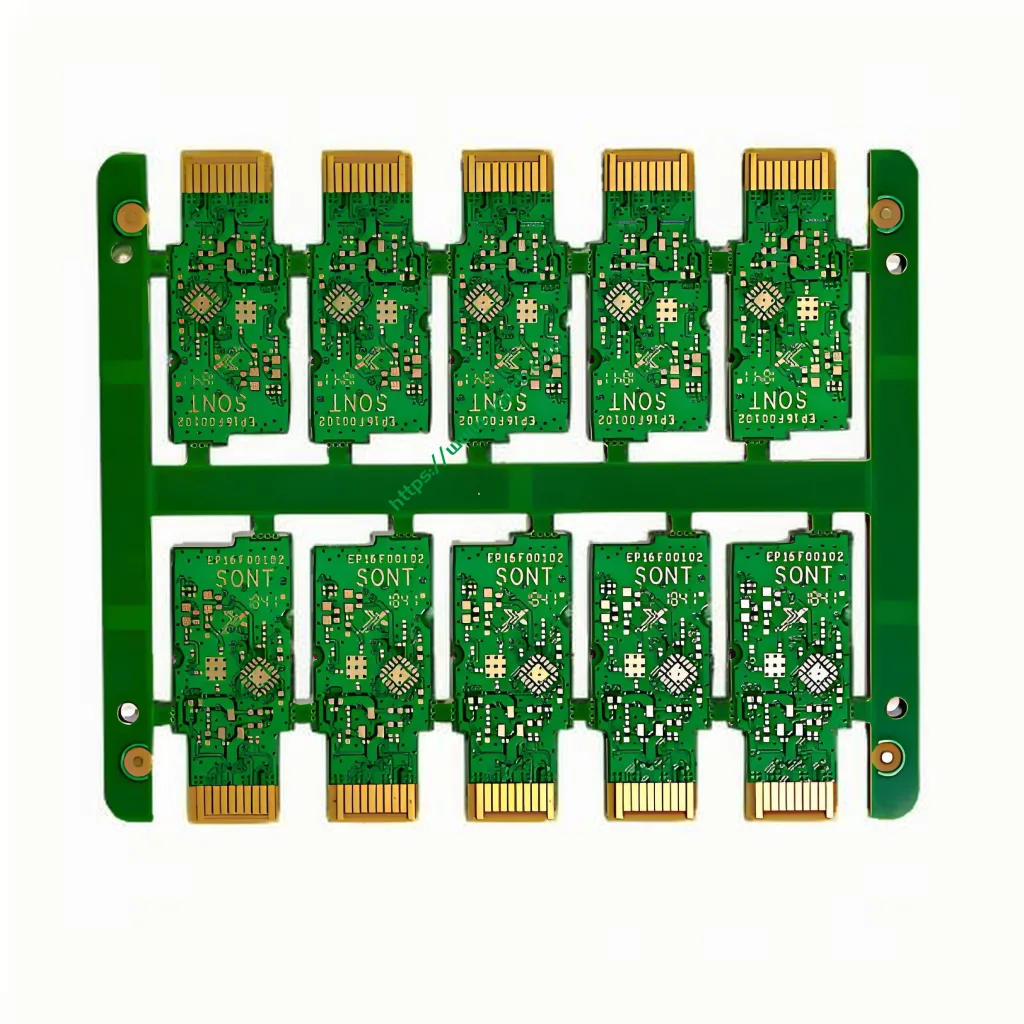

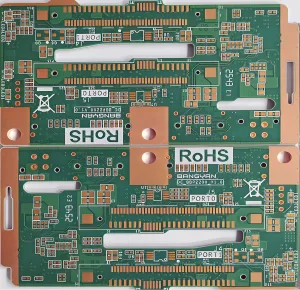

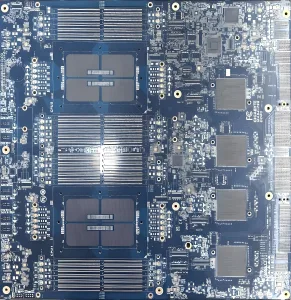

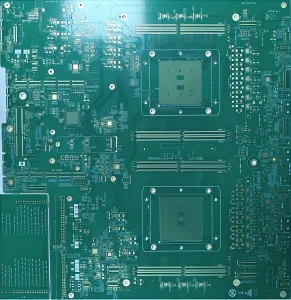

Fibre-Optical Module PCBs, also known as Fiber Optic Boards, are specialized circuiti stampati (PCB) designed for use in fiber optic communication systems. Questi PCB are integral components in modern telecommunications and data transmission networks due to their ability to handle high-speed data transfer with minimal signal loss.

Scopo e applicazione

The primary purpose of a Fibre-Optical Module PCB is to provide a reliable platform for mounting and interconnecting optical components such as lasers, photodetectors, and other optoelectronic devices. These PCBs are commonly used in:

- Attrezzatura di telecomunicazioni

- Data center

- High-speed networking devices

- Medical imaging equipment

- Sistemi di automazione industriale

Classificazione

Fibre-Optical Module PCBs can be classified based on several criteria including:

- Numero di strati (per esempio., single-layer, a doppia faccia, multistrato)

- Material composition (per esempio., MEGTRON 6, Panasonic M6)

- Controllo dell'impedenza (per esempio., 50 ohm, 100 ohm)

- Trattamento superficiale (per esempio., oro di immersione, gold fingers)

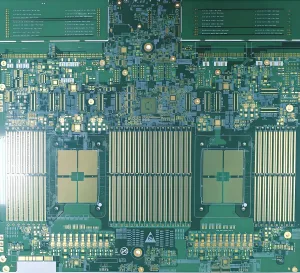

Material and Build

Materiale

The Fibre-Optical Module PCB utilizes MEGTRON 6, noto anche come Panasonic M6, which is a high-performance material offering excellent thermal stability and mechanical strength. This makes it ideal for applications requiring durability and reliability.

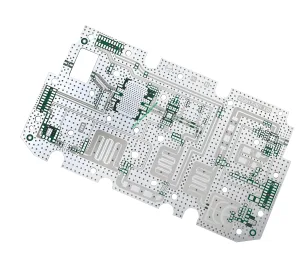

Dettagli di costruzione

- Strati: Il PCB è composto da 8 strati, providing ample space for complex circuit designs and component placement.

- Colore: Disponibile in verde e bianco, allowing for easy differentiation and identification in various applications.

- Spessore finito: The PCB has a finished thickness of 1.0mm, optimizing both structural integrity and space efficiency.

- Spessore del rame: Con uno spessore di rame di 1 oz (oncia), Il PCB garantisce una conduttività elettrica efficiente.

Caratteristiche delle prestazioni

- Controllo dell'impedenza: The PCB maintains impedance values of 100 ± 7% E 50 ± 10%, ensuring consistent signal transmission quality.

- Velocità: Capable of handling speeds up to 400g, renderlo adatto per applicazioni ad alta frequenza.

- Tolleranza: The tolerance between the gold finger and plate edge is ±0.05mm, ensuring precise alignment and connection reliability.

Processo di produzione

The manufacturing process of a Fibre-Optical Module PCB involves multiple stages including:

- Preparazione del materiale: Selecting and preparing the base material (MEGTRON 6).

- Stacking strato: Stacking multiple layers of the Materiale PCB to achieve the desired thickness and functionality.

- Incisione di pattern: Using chemical etching or laser cutting to create the circuit patterns on each layer.

- Laminazione: Comprimere gli strati insieme ad alta pressione e temperatura per formare un'unità coesa.

- Placcatura: Applying copper plating to the PCB surface to ensure good electrical connectivity.

- Trattamento superficiale: Treating the surface with immersion gold and adding gold fingers to improve conductivity and corrosion resistance.

- Controllo di qualità: Condurre test rigorosi per garantire che il PCB soddisfi tutte le specifiche delle prestazioni.

Caratteristiche chiave e vantaggi

- Alta integrità del segnale: Maintains signal purity over long distances, crucial for fiber optic communications.

- Durata: Made from robust materials that withstand harsh environmental conditions.

- Precisione: High precision in manufacturing ensures reliable connections and minimal signal loss.

- Versatilità: Suitable for a wide range of applications due to its adaptable design and material properties.

Scenari di utilizzo

Fibre-Optical Module PCBs are essential in scenarios where high-speed data transmission is critical, ad esempio:

- Telecommunication Networks: Ensuring seamless data flow across vast distances.

- Data Centers: Supporting the backbone of data storage and retrieval operations.

- Attrezzatura medica: Enhancing the performance of diagnostic and imaging devices.

- Applicazioni industriali: Facilitating automation and control systems with high precision and reliability.

Insomma, the Fibre-Optical Module PCB represents a pinnacle of technological advancement in the realm of high-speed data communication. Its meticulous design, superior materials, and stringent manufacturing processes collectively contribute to its unparalleled performance and reliability, making it an indispensable component in modern telecommunications and data center infrastructures. Whether it’s enabling lightning-fast internet connections or ensuring the accuracy of medical imaging, this PCB stands as a testament to human ingenuity in harnessing the power of light for information transfer.

LOGO UGPCB

LOGO UGPCB