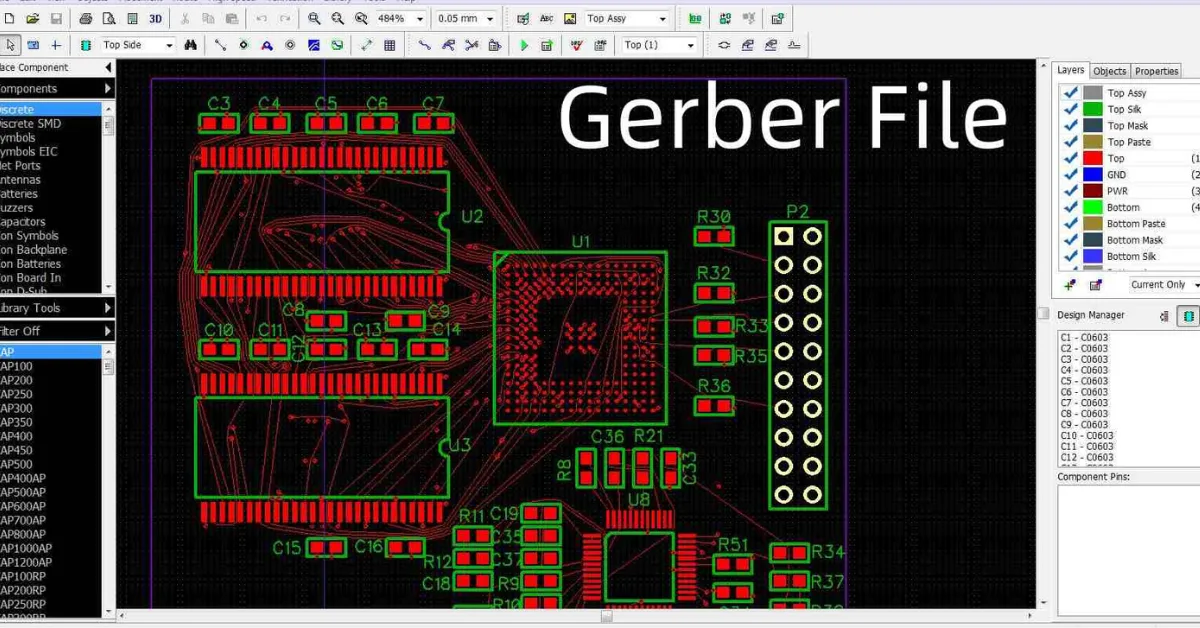

導入: Gerberファイル - PCB製造のDNA

で 高速PCB設計, Gerberファイルは上にカプセル化されます 90% 製造データの. IPC-2581標準によると, 85% グローバルの PCBメーカー 主要な生産文書としてガーバーに頼ってください. As the “industrial blueprint” of electronics, ガーバーファイル層状エンコードを通じて回路基板の物理構造を正確に説明します. このガイドは、各レイヤーのエンジニアリングの重要性をデコードして、マスターを支援します PCB製造.

セクション 1: 完全なガーバーファイルエクスポートワークフローを完了します

1.1 輸出前の確認

-

DRC検証: IPC-2221標準の間隔コンプライアンスを確保します (分. Trace/Space = 0.1mm @ 6-Layer プリント基板)

-

スタックアップ確認: インピーダンス制御が満たされなければなりません:

どこ H =誘電体の厚さ, w =トレース幅, T =銅の厚さ (1 OZ = 35µm).

1.2 エクスポートモードの比較

| 方法 | 使用事例 | ファイルの完全性 |

|---|---|---|

| ワンクリックエクスポート | 標準 4-6 レイヤーPCB | 95% |

| カスタム構成 | HDI PCB / ブラインド/埋葬バイアス | 100% |

セクション 2: ガーバーレイヤー構造ディープダイビング

2.1 導電性層が説明しました

銅層:

-

上/下層: 表面ルーティング (タイプ. 1 oz銅)

-

内層: 6-PCBスタックアップを層にします: 上部シグナル電力 - 署名底部

ドリルレイヤー:

2.2 プロセスサポートレイヤー

はんだマスク層:

-

負の画像出力 (銅の開口部を公開します)

-

分. クリアランス: 0.07mm (はんだマスクブリッジングの故障を防ぎます)

マスクレイヤーを貼り付けます:

-

ステンシルaperture =パッドサイズ× 90%

-

QFNパッケージには、クロスブリッジアンチソルダービーズデザインが必要です

シルクスクリーン層:

-

テキストの高さ≥0.8mm, ライン幅≥0.15mm

-

ボトムレイヤーシルクスクリーンにはミラーリングが必要です

セクション 3: MultiLayer PCBのGerber機能

3.1 レイヤーカウント対. ガーバーファイル

| PCBレイヤー | ガーバーファイル | 特別な要件 |

|---|---|---|

| 1-2 | 8-10 | 標準的なスルーホール |

| 4-6 | 15-20 | インピーダンス制御 + vippo |

| 8+ | 25+ | ブラインドバイアス + ハイブリッドスタッキング |

3.2 高度なプロセスの実装

vippo (ヴィアインパッド):

-

穴の直径≤0.15mm, パッドサイズ≥0.3mm

-

Label as “μVia” in drill layers

ステップスロットデザイン:

-

MechanicAllayer Annotation:

SLOT:3.0x1.2mm @ Layer2-4

セクション 4: Gerberデータによって駆動されるDFMルール

4.1 製造可能性チェック

4.2 高速設計マーカー

-

微分ペア:

IMPEDANCE:100Ω±10% -

RFトレース:

NO_SOLDERMASK(DKバリエーションを減らします)

セクション 5: レイアウトエンジニアからPCBアーキテクトまで

真のPCBAデザインの専門家マスター:

5.1 信号の完全性 (そして)

-

遅延制御: ΔL≤0.05√ε_r (PS/インチ)

-

クロストーク予防: 3wルール (間隔≥3×トレース幅)

5.2 パワーの完全性 (PI)

-

ターゲット インピーダンス:

-

デカップリングコンデンサレイアウト: 静電容量による放射状の配置

5.3 熱管理

-

銅電流容量:

I =0.048⋅ΔT0.44⋅A0.725

(ΔT=温度上昇, a =断面)

結論: ガーバーファイルの工学哲学

ガーバーデータをエクスポートするとき, 覚えて: These “cold” layers represent precision dialogues between electronics and materials science. 0.05mmレーザードリルから10μmはんだマスクトレランスまで, 各ガーバー層は、信号分離と導電性経路の工学哲学を語ります.

業界のデータが明らかにしています: Gerber+ODB ++を使用すると、デュアルファイル配信は最初のパス収量を増加させます 40%. 5G/AI時代, マスターガーバーセマンティクスは、インテリジェントハードウェア製造のコアを制御することを意味します.