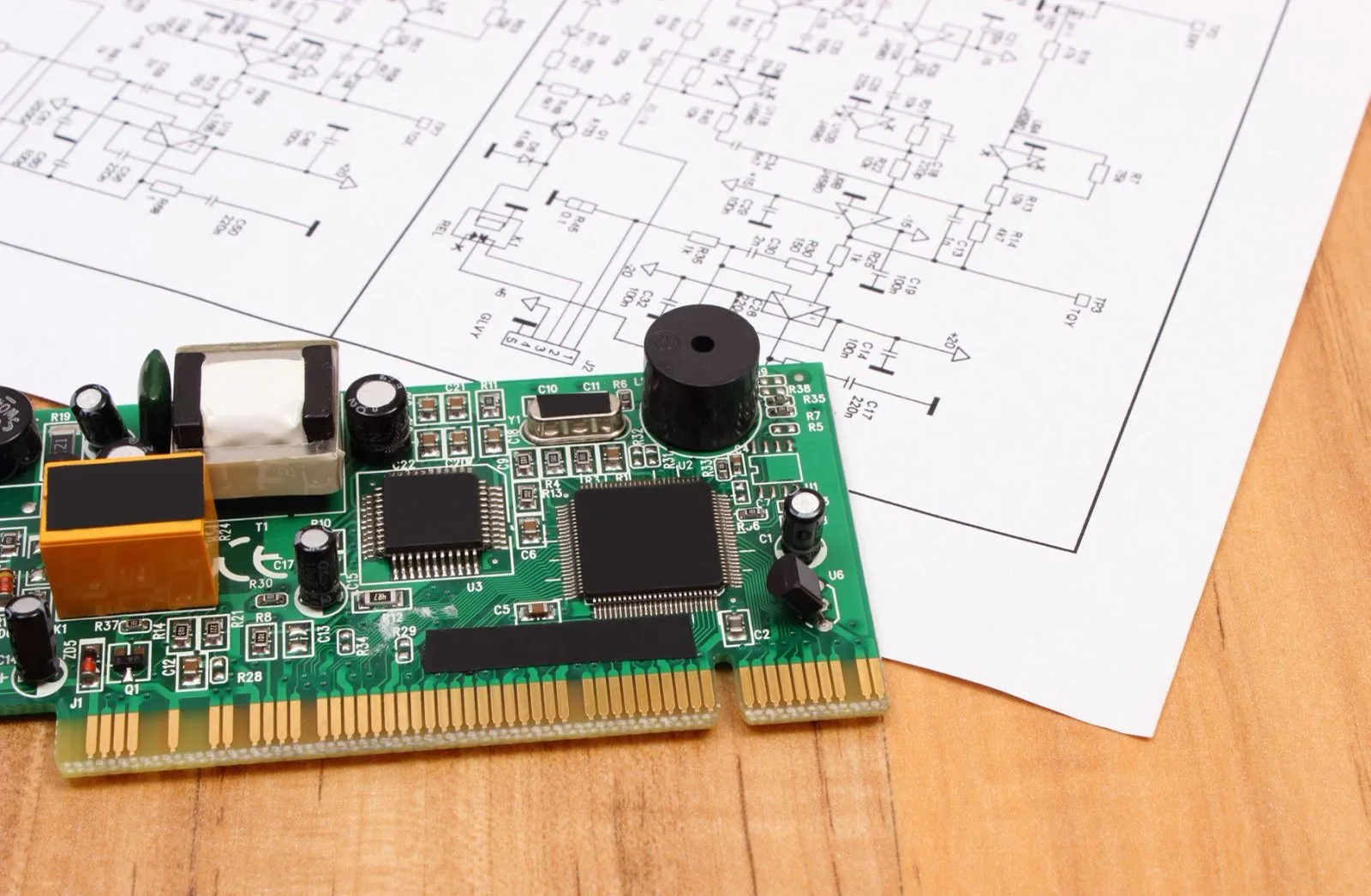

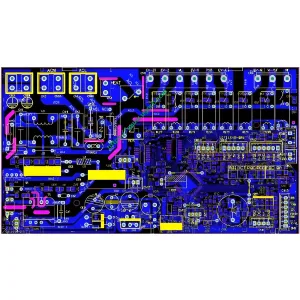

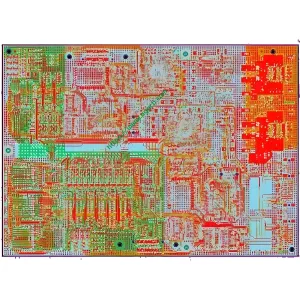

標準的な PCB 設計

標準的な PCB 設計: 高コストのパフォーマンスと信頼性の高い相互接続ソリューションの産業慣行

家電の分野で, 産業用制御, そして物事のインターネット (IoT) デバイス, 標準のPCB設計は、以下の基本的な相互接続のニーズを引き受けます 80% 電子システムの. 従来の工業デザインの最適化に焦点を当てています 1 – 12 PCBボードをレイヤーします. 科学的構造計画を通じて, 正確なプロセス適応, インテリジェントな製造プロセス制御, グローバルな顧客にコストを提供します – 効果的で信頼できる大量生産ソリューション. 私たちは累積的に多くをより多く配達しました 50 百万平方フィートの標準回路基板.

コア技術機能

ユニバーサルPCB設計最適化

- FRなどの従来のPCB材料をサポートします – 4, cem – 1, およびアルミニウムベース, ライン幅/ライン間隔の精度が±0.05mmに達し、最小穴の直径0.3mmに達します, IPCに会う – あ – 600 クラス 2 標準.

- インテリジェントパネルネスティングアルゴリズムが開発されています, 材料の利用を増やします 93% 全体的なコストを削減します 15% – 20%.

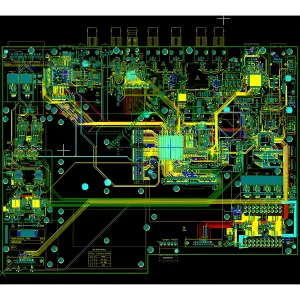

混合信号互換設計

- パワーの完全性を採用します (PI) デジタル/アナログ回路を有効にするための平面セグメンテーションテクノロジー – ボードデザイン (クロストーク抑制 > 25DB).

- 動的インピーダンス制御スキームを実装します (耐性±10%) 媒体に適しています – USBなどの速度信号プロトコル 3.0 そしてバスをすることができます.

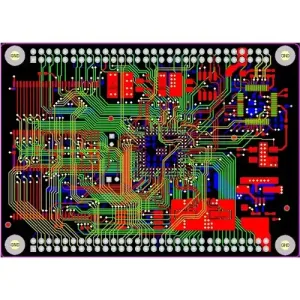

製造可能性深い相乗効果

- DFMチェッカーエキスパートシステムを統合して、自動的に多くを識別します 20 パッドピッチ/穴の直径比などのリスクポイントを処理します.

- ガーバーを提供します – に – G – PCBボードの設計と生産データのシームレスな統合を確保するための自動変換をコード.

工業製造の利点

効率的な大量生産能力

- 完全に自動化された生産ラインは、300,000〜の毎月の容量をサポートしています, の最速での配送時間があります 24 ダブルの時間 – 側面PCBボードプロトタイピング.

精密プロセス制御

- ±8μmのライン幅耐性を持つエッチング補償技術.

- の銅メッキの厚さ 18 – 25μm (IPCに準拠しています – 6012E標準).

- グリーンオイルブリッジコントロール≥0.1mm (波のはんだ付けを防ぐため).

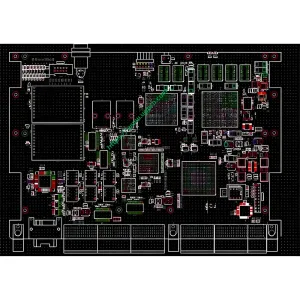

検出システム

- 100% AOI光学検出の実装 (0.02mm²の最小欠陥認識面積).

- 熱ストレステストのためのサンプリング (288℃/10Sでの耐熱性はんだ).

業界アプリケーションソリューション

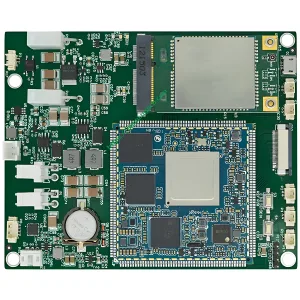

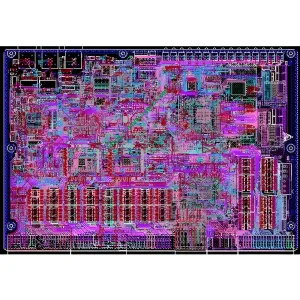

スマートホーム

- デザイン 6 – WiFi/Bluetoothモジュールと統合されたハイブリッドPCBボードをレイヤーします, 大量生産量の降伏率を超えています 99.2%.

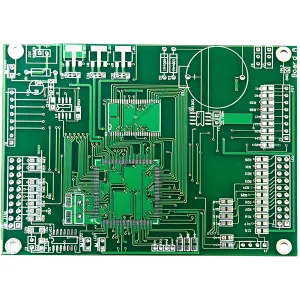

産業コントローラー

- 発展します 4 – 重い銅板を重ねます (3オンス) 通過 1000 – 時間塩スプレーテスト (IEC 60068 – 2 – 52).

カーエレクトロニクス

- 提供します 12 – レイヤースルー – 温度抵抗範囲のホールボード – 40℃〜125℃, AECによって認定されています – Q100.

標準化されたサービスの価値約束

料金 – 最適な戦略

- マテリアルライブラリは以上をカバーしています 30 ShengyiやTaiguangなどのブランド, 階層化された価格設定スキームを提供します.

迅速な応答システム

- 内の設計相談に関するフィードバック 4 時間.

- プロジェクト確認の完了 8 – 内部のレイヤーボード 48 時間.

品質保証

- IPCクラスを実装します 2/3 標準段階的なコントロール.

- 3番目を提供します – 当事者CNAS検査報告書.

今すぐ行動を起こしてください: 最大のコストを得るために、私たちの専門のPCBデザインエンジニアチームにすぐに相談してください – 効果的な引用.

基本設計を並外れた品質を達成させます – 私たちは、すべての回路基板の信頼できる遺伝子を産業の精度で保護します.

UGPCBのロゴ

UGPCBのロゴ

微信

WeChat で QR コードをスキャンします