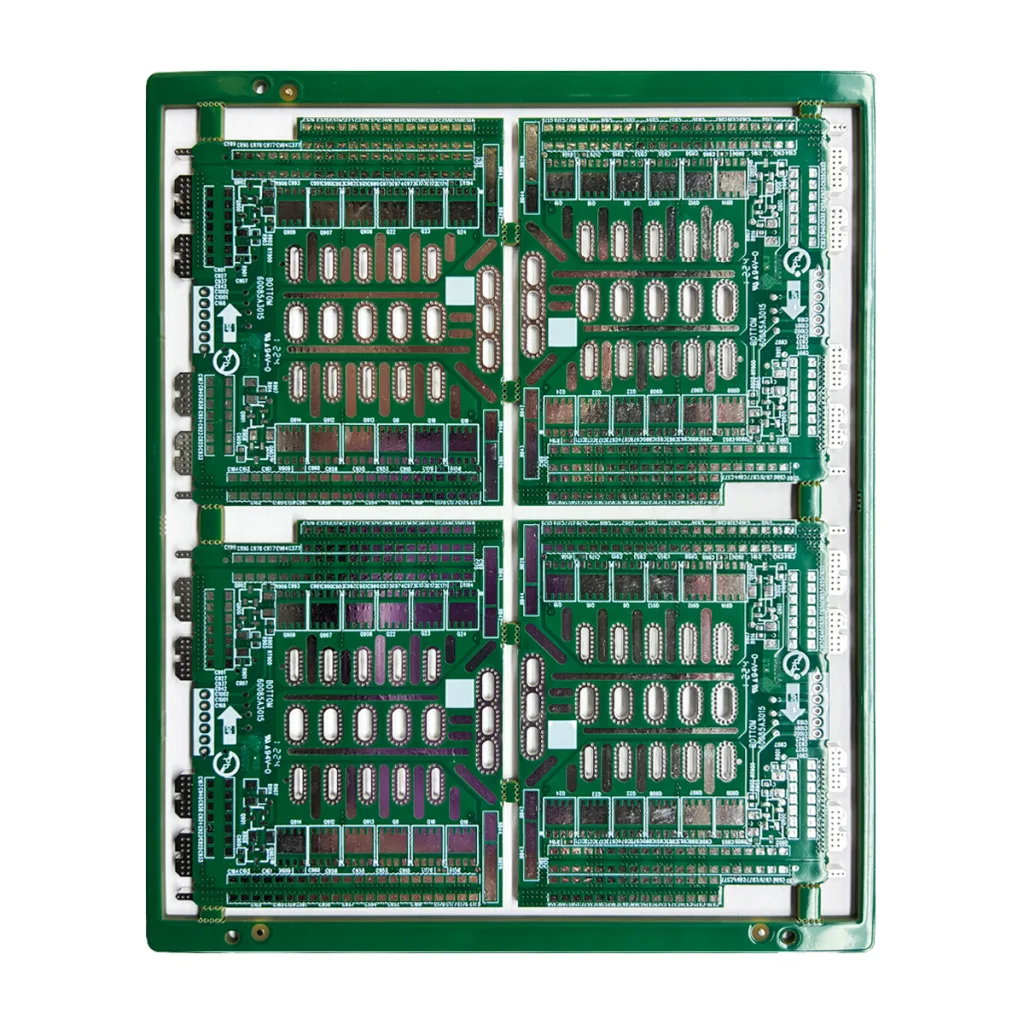

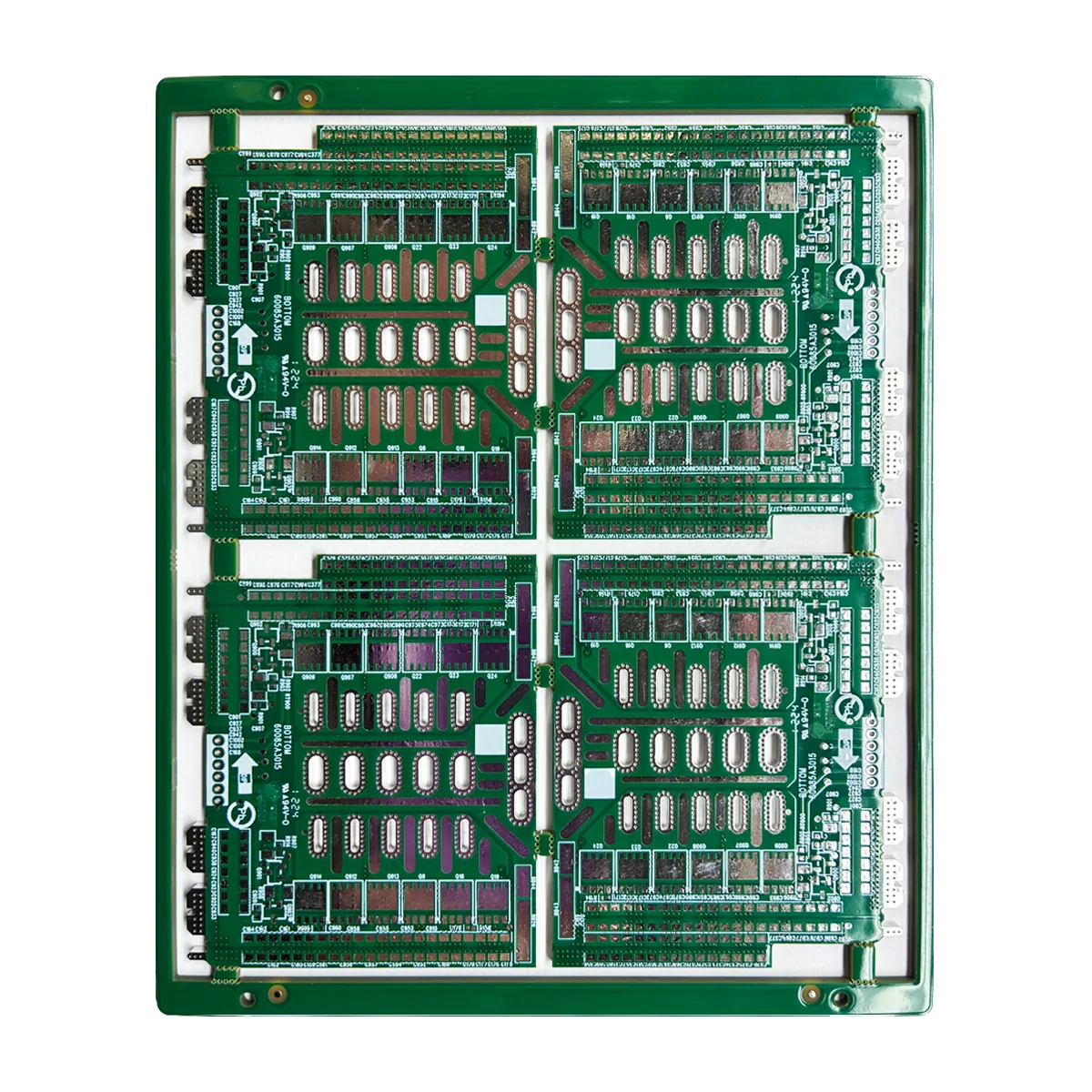

High-Reliability 8-Layer Rigid PCB 製品の概要 & 意味

In the realm of high-speed, high-density electronic design, 多層PCB (プリント基板) are indispensable. UGPCB 8-層リジッドPCB, built with a substantial 2.0mm board thickness そして 3OZ heavy copper foil, is engineered to withstand demanding electrical and physical environments. It serves not only as the foundation for electrical connectivity but as a critical component ensuring device stability and enhanced product reliability. For applications in industrial controls, power systems, または自動車エレクトロニクス, this high-specification board is the optimal solution for complex, high-performance designs.

コア仕様

-

レイヤー数: 8-レイヤーリジッドPCB

-

Finished Board Thickness: 2.0mm±10%

-

基本材料: FR-4, ガラス転移温度 (TG) ≥ 170°C

-

表面仕上げ: Lead-Free Hot Air Solder Leveling (HASL-LF)

-

銅の重量: 3 1平方フィートあたりのオンス (≈105μm) for both inner and outer layers

-

はんだマスク & シルクスクリーン: Green LPI Solder Mask, White Silkscreen Legend

設計上の重要な考慮事項

When designing with this high-specification PCB, engineers must prioritize:

-

熱管理: Leverage the high current-carrying capacity of 3OZ heavy copper to optimize power and ground planes, reducing impedance and heat rise. Use thermal simulation in conjunction with the high heat resistance of FR-4 TG170 material.

-

インピーダンス制御 & 信号の完全性: The 8-layer stack-up allows effective separation of signal, 力, とグランド層. Precise calculation and control of trace impedance (例えば。, 50Ω シングルエンド, 100Ω differential) is essential to minimize reflection and crosstalk.

-

機械 & Electrical Reliability: The 2.0mm thick board enhances overall rigidity, suitable for applications with vibration or insertion stress. For high-voltage or high-current nodes, adjust trace width and clearance according to IPC-2221 standards そして 3OZ copper weight to ensure safety margins.

-

DFM (製造可能性のための設計): Collaborate with UGPCB’s engineering team early to address specific requirements for heavy copper PCB そして thick board PCB 処理, such as drilling parameters and plating uniformity, ensuring a high-yield manufacturing process.

それがどのように機能するか & 構造

An 8-層PCB is fabricated by laminating multiple conductive layers into a single unit using precise processes including inner-layer imaging, ラミネーション, 掘削, とメッキ. Electrical connections between layers are established via plated through-holes (pths), ブラインドビア, or buried vias. A typical stack-up example is:

最上層 (信号) — Prepreg — L2 (地面) — Core — L3 (信号) — Core — L4 (力) — Core — L5 (信号) — Prepreg — Bottom Layer (信号)

これ “sandwich” structure effectively isolates high-speed signals, provides solid reference planes, and ensures efficient power distribution.

パフォーマンス & 主な特長

-

Superior Electrical Performance: 3OZ heavy copper provides extremely low conductor resistance and excellent current-carrying capacity (over 3x that of standard 1OZ copper), reducing power loss and voltage drop.

-

Exceptional Thermal Reliability: FR-4 TG170 high Tg material withstands higher operating and soldering temperatures. Combined with the thermal conductivity of heavy copper, it significantly improves long-term reliability in high-temperature environments.

-

Enhanced Mechanical Stability: The 2.0mm thick board combined with rigid FR-4 offers superior resistance to bending and vibration, ideal for harsh operating conditions.

-

High Solder Joint Reliability: The HASL-LF surface finish アパートを提供します, coplanar pad surface with excellent solderability and extended shelf life, compliant with RoHS directives.

-

高密度相互接続 (HDI) Capability: The 8-layer design offers ample routing space for complex circuits, facilitating device miniaturization and functional integration.

製造工程の概要

Engineering Review → Material Cutting (FR-4 TG170) → Inner Layer Imaging & エッチング (3オズ) → Oxide Treatment & Lamination → Mechanical Drilling & Copper Plating → Outer Layer Patterning & メッキ (to 3OZ) → ソルダーマスク塗布 (Green LPI) & シルクスクリーン (白) → Lead-Free HASL Surface Finish → Electrical Testing & 最終検査 (per IPC standards)

Each stage incorporates stringent quality control checkpoints to ensure every high-reliability multilayer PCB meets exact customer specifications.

主要なアプリケーション & ユースケース

This PCB is designed for high-power, high-stability applications:

-

Industrial Control Systems: plcs, motor drives, and industrial power supplies requiring heavy copper PCBs for high current.

-

再生可能エネルギー & Power Systems: Solar inverters, UPS systems, and EV charging modules relying on high current capacity and thermal endurance.

-

カーエレクトロニクス: On-Board Chargers (OBC), Battery Management Systems (BMS), and DC-DC converters, どこ high Tg PCBs are essential for under-hood temperatures.

-

通信インフラストラクチャ: Base station power amplifier units and network backup power systems.

-

ハイエンドテスト & 測定機器: Instruments requiring stable power delivery and low-noise performance.

製品分類 (Per IPC Standards)

-

レイヤーカウントごとに: 多層プリント基板 (>4 レイヤー), specifically an 8-層回路基板.

-

By Rigidity: リジッドPCB.

-

ベース素材によって: FR-4基板, subset: 高TG PCB (Tg ≥ 170°C).

-

By Special Process: 重い銅の PCB (per IPC-2152), Thick Board PCB.

-

By Application Class: Suitable for IPCクラス 2 (Dedicated Service Electronic Products) そして クラス 3 (High-Reliability Electronic Products) アプリケーション, 含む Industrial Grade PCB, Power Electronics PCB, そして Automotive Grade PCB.

UGPCBのロゴ

UGPCBのロゴ