導入: グリーン PCB 製造の基礎 – コンプライアンスから卓越性へ

持続可能なエレクトロニクス製造への世界的な移行において, 環境規制は基本的な要件となっている. EUのRoHS 2.0 指令は重要な標準です, 鉛やカドミウムなどの有害物質の制限. のために PCBメーカー の市場にサービスを提供する 家電, 自動車エレクトロニクス, および医療機器, しっかりした物質管理が不可欠.

UGPCB はこの標準に準拠しています. 私たちはあらゆる環境保全を確保します。 回路基板 原材料から完成品まで一貫して管理されています PCBAアセンブリ. 最先端の RoHS への投資 2.0 コンプライアンス システムは、当社の品質保証を戦略的にアップグレードするものです, ~の信頼できる基盤を提供する “ゼロリスク” 製品.

一部 1: 原子レベルの精度 – UGPCB の高度な RoHS 2.0 検出

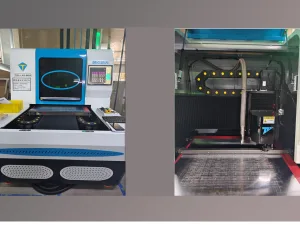

当社のRoHS 2.0 エネルギー分散型蛍光X線を利用したシステム (ED-XRF) 精密な材料分析技術.

1. コアテクノロジー: 原子レベルの識別

このシステムはサンプル内の原子を励起します。, 独特の蛍光X線を発生させる. 高分解能シリコンドリフト検出器 (SDD) これを捕らえます “指紋,” 鉛などの規制物質の特定, カドミウム, 水銀, 臭素系難燃剤を高精度で供給.

2. パフォーマンスのベンチマーク

-

広範囲 & 低い検出限界: すべてのRoHSをカバー 2.0 物質, 検出限界あり (例えば。, カドミウムについては 2 ppm 以下) 規制基準よりもはるかに厳しい.

-

高効率 & 安定性: 高速分析 (サンプルあたり 90 秒以下) 優れた再現性 (RSD ≤1%) 大容量をサポート プリント基板の製造.

-

幅広いサンプル互換性: 固体を処理します, 液体, と粉末, に適した PCBラミネート, インク, 化学物質, 完成したPCBAアセンブリ.

一部 2: フルライフサイクルグリーン管理 - UGPCB システム

高度なテストを包括的な管理フレームワークに統合します.

1. ソース管理

徹底したグリーン調達を実施します. すべてのサプライヤーは有効なコンプライアンス証明書を提供する必要があります, すべての材料バッチは受領時に検査されます.

2. プロセスの防止

ひたむきな 鉛フリー PCBアセンブリ ハロゲンフリーラインにより二次汚染を防止. SAC305はんだなどの認定材料を使用し、プロセスを最適化します。 (例えば。, 制御されたリフロープロファイル) 信頼性とコンプライアンスのために.

3. 最終検証 & トレーサビリティ

終了した PCBAボード 検証を受ける, 第三者によるテストによって補足される. すべてのデータは当社の MES に記録され、原材料から最終出荷まで完全なトレーサビリティを実現します。.

一部 3: テストを超えて – PCBA プロジェクトを強化する

私たちの能力はあなたのプロジェクトに直接的な価値をもたらします.

1. 市場アクセスを加速する

当社が検証済み グリーン製造ソリューション と文書化は、認証サイクルを短縮し、規制市場における法的リスクやリコールのリスクを軽減するのに役立ちます。.

2. 高信頼性アプリケーションをサポート

のために 自動車PCB または 医療機器の回路基板, 物質に対する当社の正確な管理により、過酷な環境における長期的な性能と信頼性が保証されます。.

3. 統合された PCB to PCBA サービス

私たちの ワンストップサービス 一貫した RoHS 準拠を保証します。 PCBプロトタイピング を通して SMTアセンブリ, サプライチェーンを簡素化し、エンドツーエンドのコンプライアンスを確保します.

結論: 持続可能なパートナーシップのためにUGPCBを選択してください

不確実な世界市場において, コンプライアンスは確実です. UGPCB の RoHS への投資 2.0 お客様の成功に対する当社の取り組みを反映しています. 私たちがお届けするのは品質だけではありません プリント基板 およびPCBAサービス, だけでなく、世界市場へのアクセスに必要な信頼と文書も必要です.

カスタムのグリーン製造ソリューションについて今すぐ UGPCB にお問い合わせください。.

UGPCBのロゴ

UGPCBのロゴ