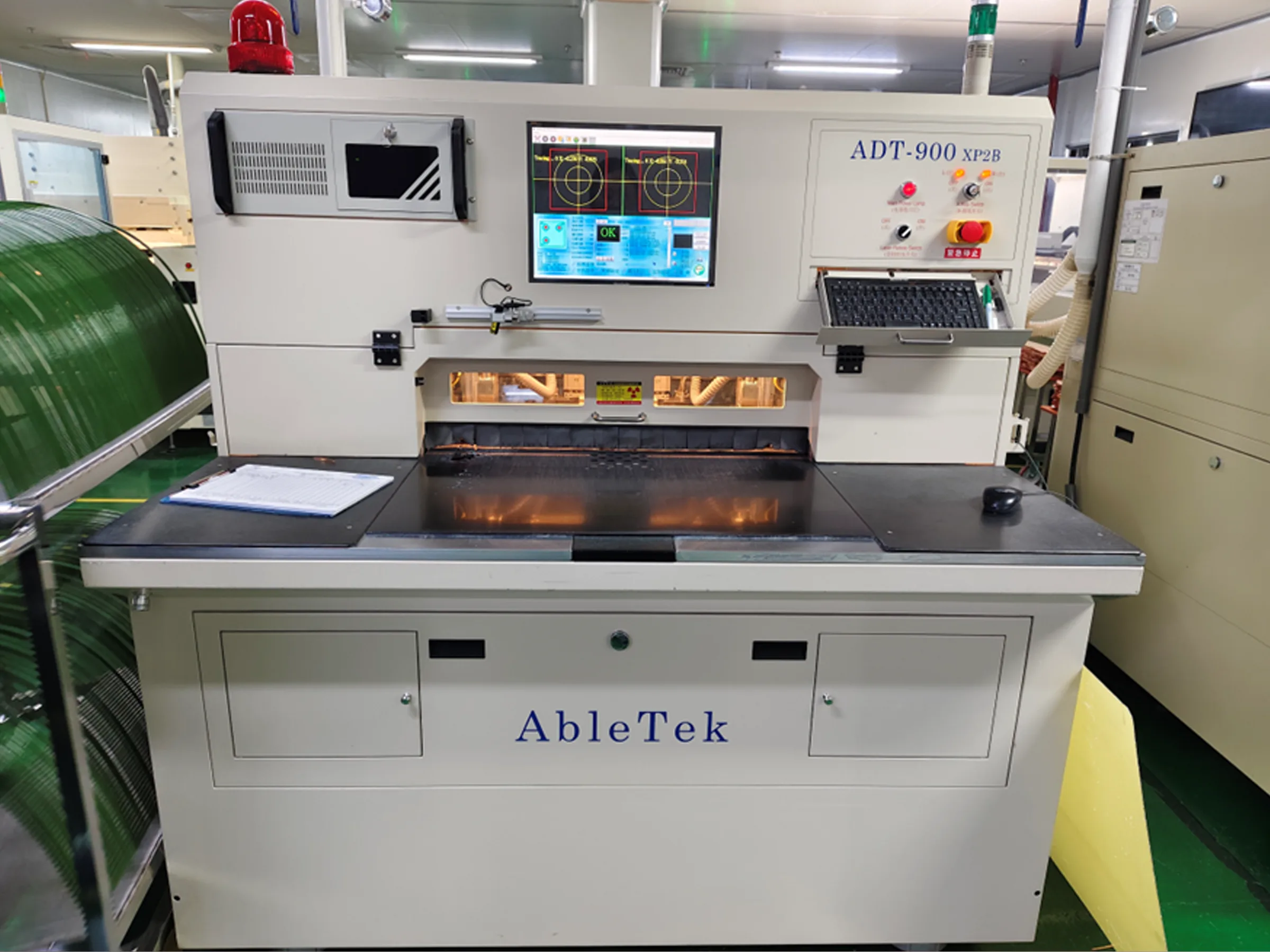

UGPCB は高度な ADT-900XP2B X 線穴あけターゲット マシンで PCB と PCBA の精度を向上させます

急速に進化するエレクトロニクス製造の世界で, 精度と信頼性 交渉不可能です. エンドツーエンドのリーディングプロバイダーとして プリント基板と プリント基板 ソリューション, UGPCB 小型化と高密度相互接続に対する高まる需要を満たすために、最先端の技術に継続的に投資しています。. 最近追加されたのは、 ADT-900XP2B X線穴あけターゲットマシン この取り組みを体現するもの, UGPCB を複合施設の頼れるパートナーとして位置付ける, 高性能 回路基板 製造業.

X線掘削ターゲットマシンADT-900XP2Bとは?

ADT-900XP2B は、次の目的のために設計された最先端のシステムです。 高精度の位置合わせと穴あけ で 多層PCB. 活用することで X線技術, 内部層の正確なターゲティングを可能にします, マイクロビアや埋め込みコンポーネントを備えた設計でも、完璧な位置合わせを保証します。. 主な機能は次のとおりです。:

-

自動キャリブレーション機能 一貫したパフォーマンスのために.

-

卓越したシステムの安定性 大量生産下でも許容レベルを維持するため.

-

インテリジェントな最適化ソフトウェア 設計の複雑さに適応する.

-

高いスループット能力, 品質を損なうことなく納期を短縮 .

このマシンは、世界における最も重要な課題の 1 つに対処します。 プリント基板の製造: 信号整合性の問題や基板の故障を防ぐために層を正確に位置合わせする. ±2 µmの開口公差と最小焦点スポットサイズ <8 μm, ADT-900XP2B は保証します 比類のない精度 .

UGPCB が ADT-900XP2B をワークフローに統合する方法

UGPCBへ, ADT-900XP2B は他の高度な機器と相乗して動作します, 新しく設置されたものなど 自動切断・研削ライン. この統合によりシームレスなパイプラインが作成されます:

-

レイヤーの準備: コア材料とプリプレグは、最適な表面均一性を実現するために自動研削システムを使用してトリミングおよび成形されます。.

-

X線掘削: ADT-900XP2B は、サブミクロンの精度でターゲットを識別して穴あけします, ブラインドビアや埋め込みビアでも.

-

穴あけ後の検査: 社内テストプロトコルによりレイヤー間の登録を検証.

このワークフローにより、次のことが保証されます。 多層PCB まで達成する 99.9% 信頼性 整列して, 航空宇宙分野のアプリケーションにとって重要, 医療機器, および5Gインフラストラクチャ.

PCB/PCBA 製造における ADT-900XP2B の技術的利点

1. 高密度相互接続のための優れた精度 (HDI) プリント基板

機械のビーム幅 1.9° (水平) と20° (垂直) 集中的なエネルギー供給を可能にする, 隣接するエリアへの巻き添え被害を最小限に抑える . これは、 HDI PCB 設計, トレース幅は次のように狭くすることができます。 25 μm.

2. 多層基板製造の効率向上

毎分 24 ~ 42 回転のスループットと 0.125 ~ 96 NM の範囲スケール, ADT-900XP2B は速度を維持しながらさまざまなパネル サイズに対応します . UGPCB はこれを活用してリードタイムを短縮します。 試作と量産 プリント基板 注文.

3. 複雑なアセンブリの信頼性の向上

システムの 閉まっている 100 kV X線源 高分解能検出器 (分解能0.5μm) 最小の位置ずれも確実に検出して修正します . これは特に次の場合に有益です リジッドフレックスPCB, レイヤーの登録が難しい場合.

自動切断・研削ラインとの相乗効果

UGPCBの新しい 自動切断・研削ライン 正確な仕様に合わせて材料を準備することで、ADT-900XP2B を補完します. 例えば:

-

精密研削 表面の凹凸をなくします, ラミネート中の均一な接触を確保.

-

自動切断 パネルサイジングにおける人的ミスを削減, これは、インピーダンス制御を維持するために重要です。 高周波プリント基板.

一緒に, これらのテクノロジーにより、UGPCB は 寸法公差±0.1mm, 業界標準をはるかに上回っている.

PCB および PCBA 製造における UGPCB の専門知識

機器を超えて, UGPCB の強みは総合的なアプローチにあります:

-

デザインサポート: エンジニアはクライアントと協力して、製造可能性を考慮して設計を最適化します。.

-

材料の選択: 大手サプライヤーとのパートナーシップにより、高品質の基板とプリプレグの使用が保証されます.

-

厳格なテスト: 回路内テスト (ICT) 自動光学検査 (あおい) すべてを検証する PCBAアセンブリ.

同社の専門知識 多層PCB製造 そして 表面実装技術 (SMT) グローバルブランドの信頼できるパートナーとなっています.

結論: UGPCB – 高度な PCB ソリューションのパートナー

ADT-900XP2B X線穴あけターゲットマシンと自動切断/研削ラインの統合は、UGPCBのイノベーションへの取り組みを強調します. テクノロジーと業界の深い知識を組み合わせることで, UGPCB が提供する 優れたPCBおよびPCBA製品 最高の品質と信頼性の基準を満たしていること.

UGPCB の利点を今すぐ体験してください! 見積もりについてはお問い合わせください 精密PCB製造 または ターンキー PCBA サービス.

UGPCBのロゴ

UGPCBのロゴ