Every microscopic advancement in packaging technology reshapes the physical boundaries of electronics.

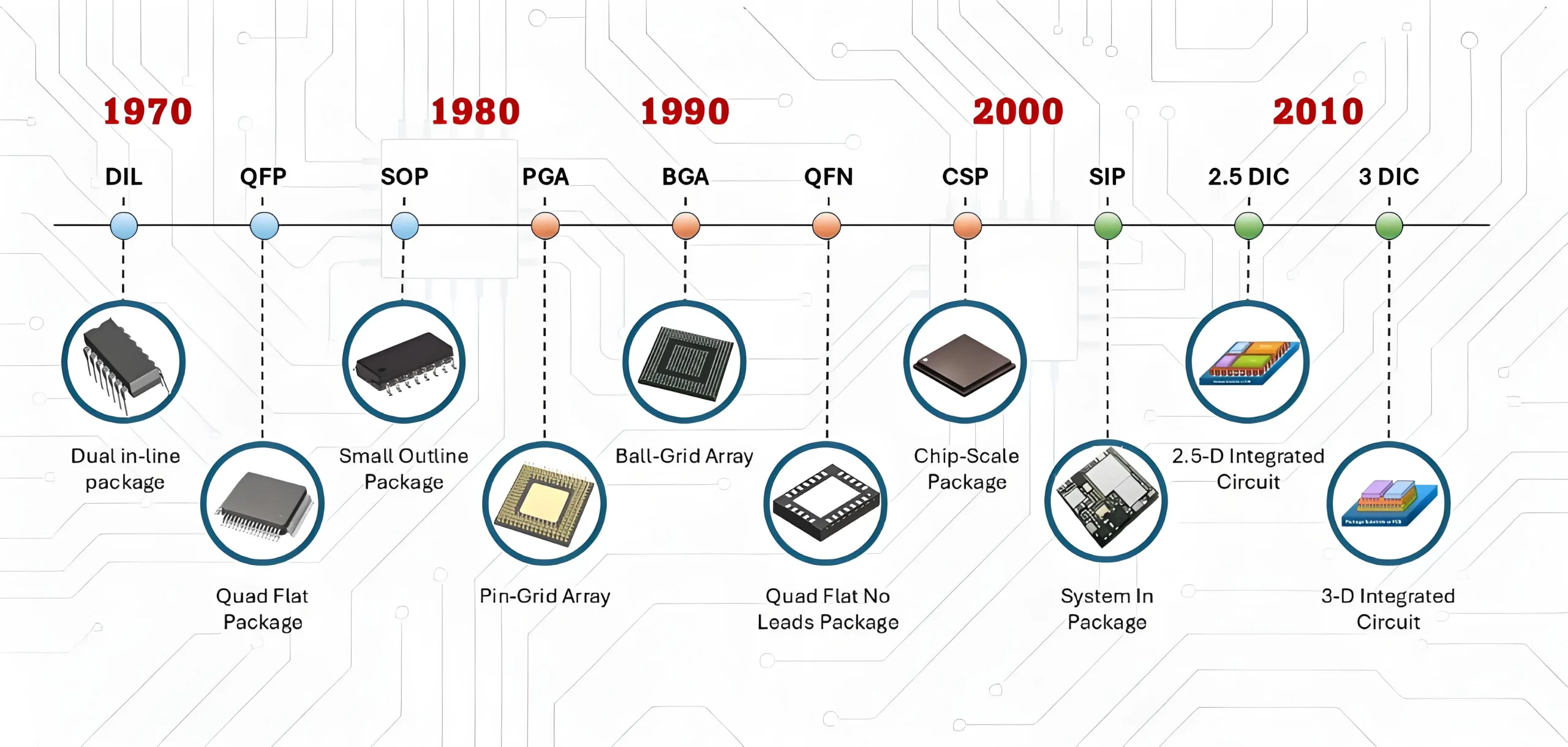

In last week’s Evolution of Chip Packaging: From DIP to X2SON – How Miniaturization Reshaped Electronics, we explored the era of through-hole packaging (DIP) and how surface-mount devices (SOP, SOJ, SON) initiated device miniaturization. While these technologies laid modern packaging foundations, the miniaturization revolution continues. Today, we examine higher-density packages—from quad-flat to wafer-level CSP—and their impact on PCB design limits.

Quad-Flat Packages: The Space-Density Balance

Quad-flat packages (QFP, PLCC/QFJ, QFN) represent a critical evolution toward higher I/O density by utilizing all four package edges.

QFP: The Gull-Wing Density Pioneer

QFP (Quad Flat Package) features iconic “gull-wing” (L-shaped) leads extending from all sides. Its pin pitch (0.4mm/0.5mm/0.65mm) dictates PCB routing density and soldering precision.

QFP Variants:

-

Size/Thickness: LQFP (Low-profile), TQFP (Thin), VQFP (Very-thin)

-

Material: PQFP (Plastic), MQFP (Metal)

-

Thermal Enhanced: HQFP, HLQFP, HTQFP, HVQFP

-

Protection: BQFP (Bumpered—corner pads prevent bent leads)

Thermal management is critical. The junction-to-ambient thermal resistance formula θja = (Tj – Ta)/P (where Tj=junction temp, Ta=ambient temp, P=power) governs heat dissipation design.

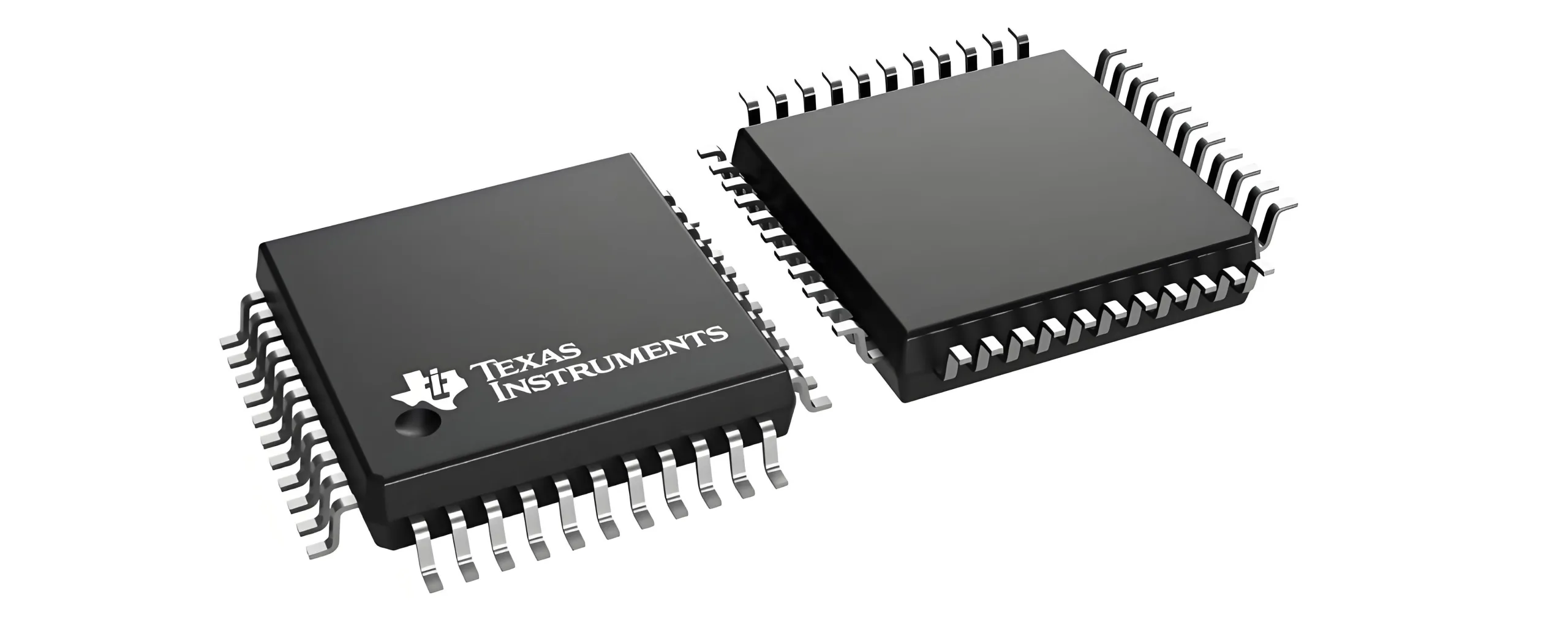

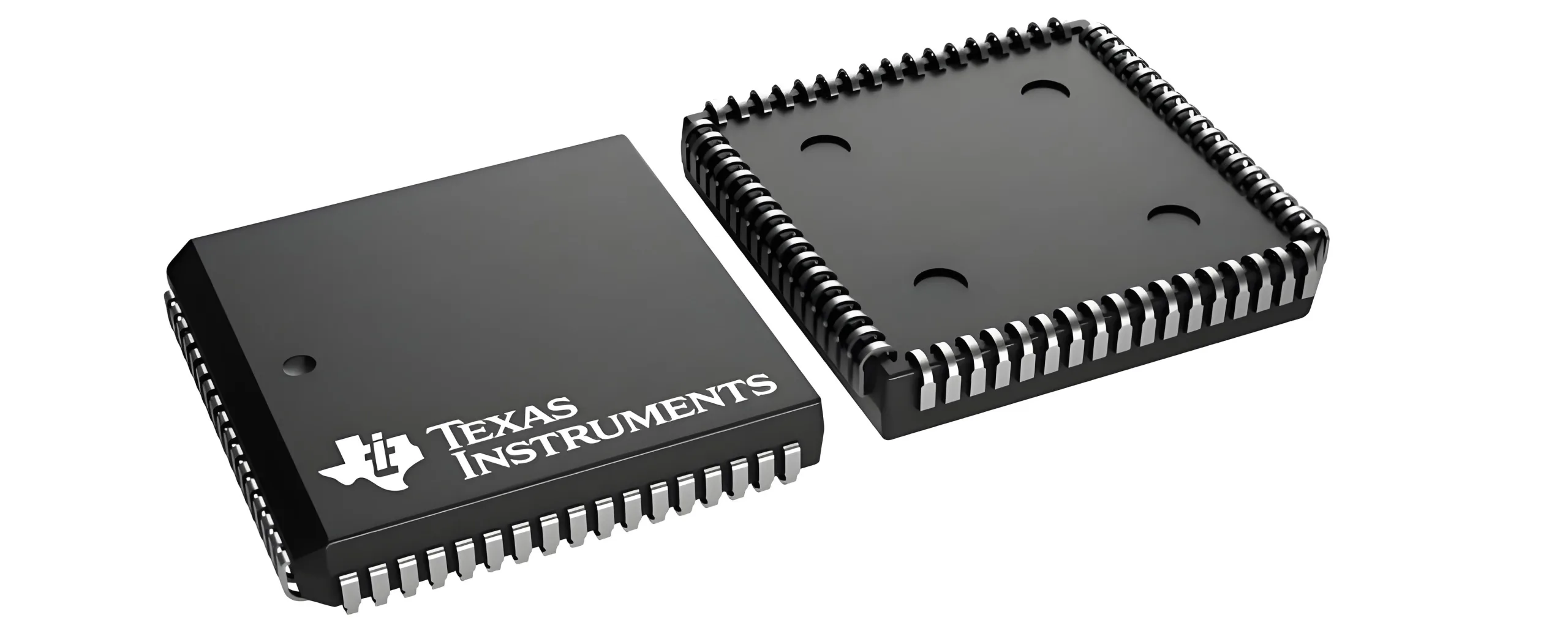

PLCC/QFJ: Stability Through J-Leads

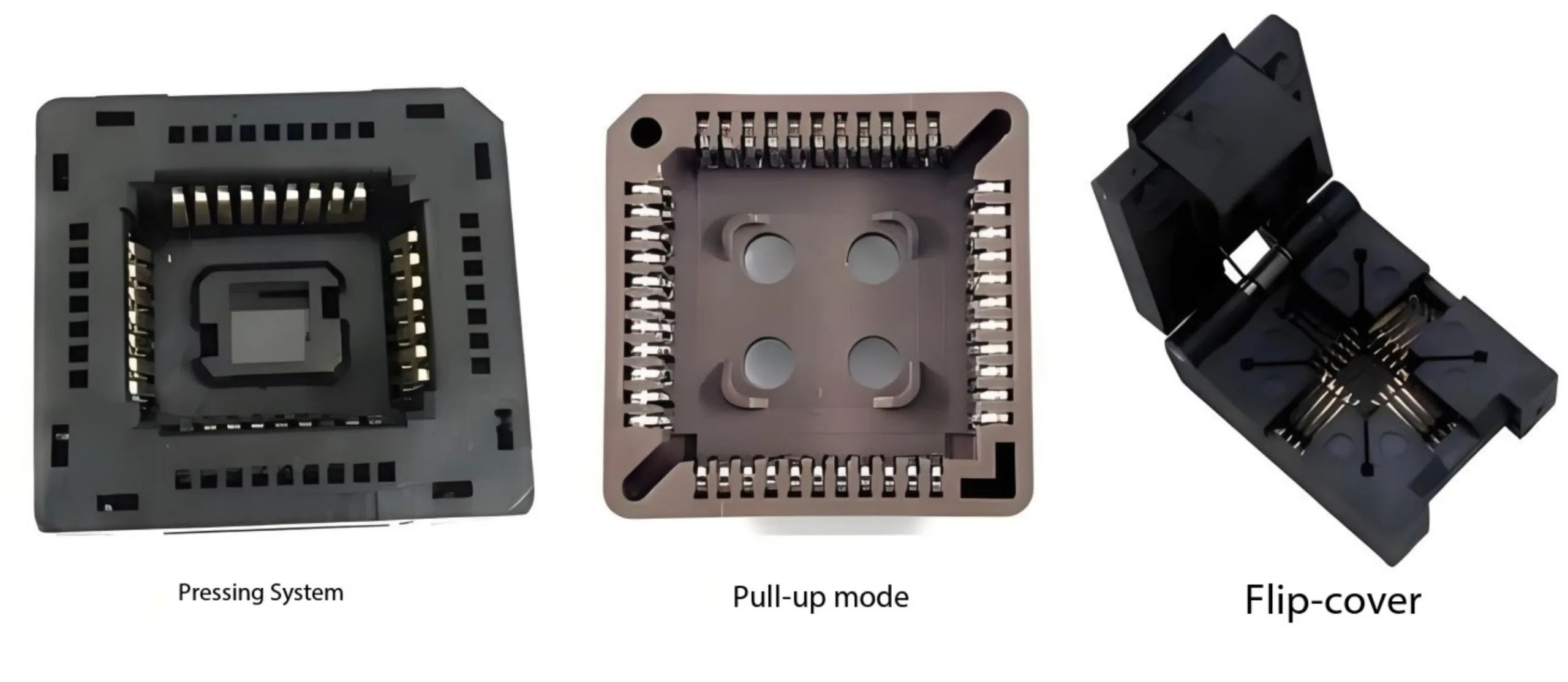

PLCC (Plastic Leaded Chip Carrier) or QFJ (Quad Flat J-leaded) uses downward-bent J-shaped leads for mechanical stability against vibration/thermal stress.

Standardization Advantage: PLCC/QFJ’s high compatibility with universal test sockets streamlines production testing. Though QFJ is technically precise, “PLCC” remains industry-preferred.

QFN: Leadless Miniaturization Breakthrough

QFN (Quad Flat No-lead) eliminates external leads, connecting via:

-

Exposed Pad (EP): Direct thermal path to PCB copper

-

Wettable Flanks: Side-wall solderable pads

Key Advantages:

-

Ultra-Compact: 40% smaller than QFP

-

Electrical Superiority: Shorter paths reduce parasitic inductance (L ≈ μ·l/w)

-

Thermal Efficiency: Lower θja vs. same-size QFP

Thickness Evolution: LQFN → UQFN → VQFN → WQFN → X1QFN → X2QFN. LCC (LPCC/LCCC) is its leadless ceramic/plastic variant.

Array Packages: Revolutionizing Density Limits

When quad-flat reaches I/O limits, array packages (LGA, BGA) enable 2D interconnect density.

LGA: Precision Elastic Connection

LGA (Land Grid Array) uses precisely aligned metal contacts (e.g., LGA775: 775 contacts) mating with socket pins.

Core Value:

-

Socketability: CPU upgrades/maintenance

-

Low Inductance: Short signal paths

-

High Reliability: Ideal for CPUs (Intel/AMD)

Limitation: High socket cost/size favors BGA in compact devices. Note: LGAs can be direct-SMT soldered.

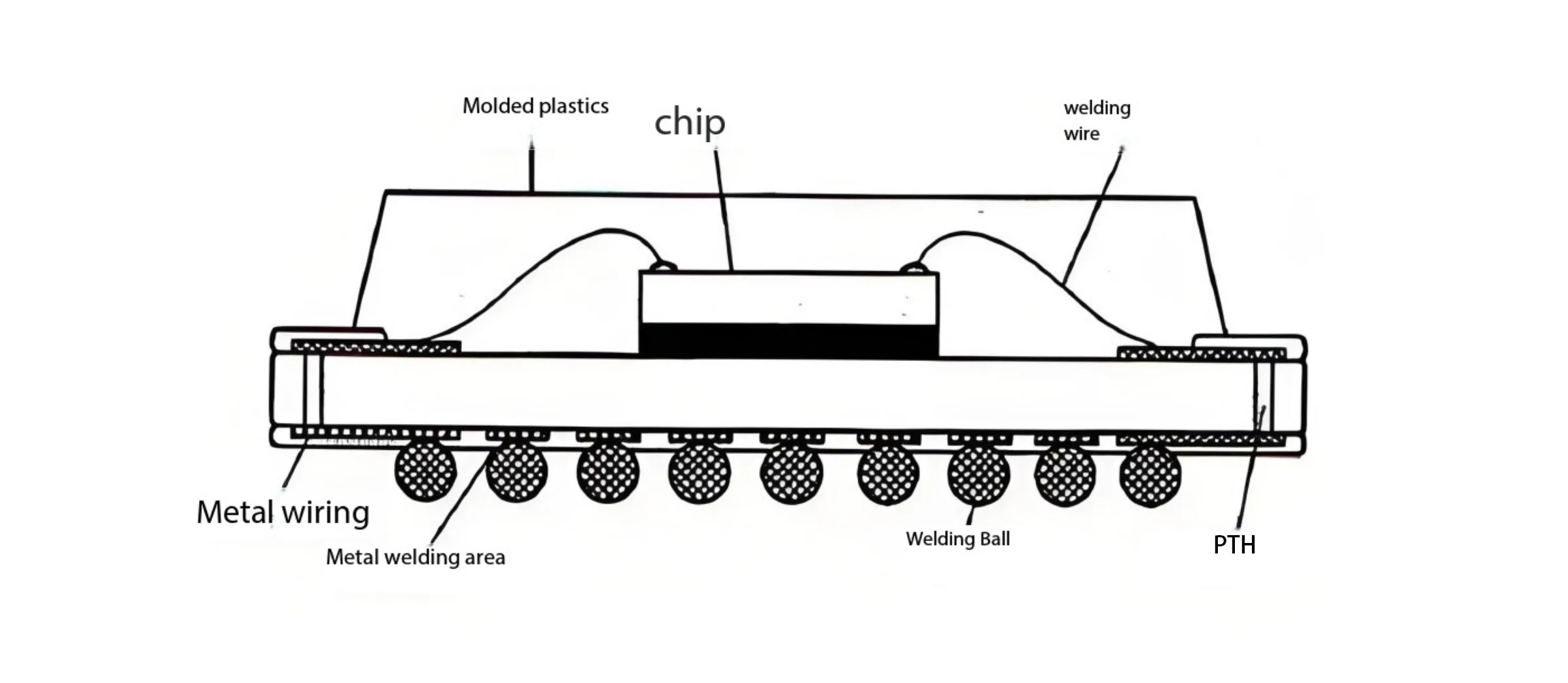

BGA: The Solder Ball Dominance

BGA (Ball Grid Array) connects via a solder ball matrix. Ball pitch (0.3–1.0mm; <0.2mm for FBGA) is critical.

Transformative Advantages:

-

High Density: >1,000 I/Os (vs. QFP’s ~300)

-

Space Saving: 30%+ area reduction vs. QFP

-

Electrical/Thermal: Low signal delay; balls conduct heat

-

Self-Alignment: Surface tension aids assembly

BGA Family:

-

Material: PBGA (Plastic), CBGA/CABGA (Ceramic)

-

Size/Pitch: nFBGA/FBGA (Fine-pitch), TinyBGA, DSBGA/WCSP (Die-size), LFBGA/VFBGA (Thin)

-

Integration:

-

FCBGA (Flip-Chip): Direct die-to-substrate connection via microbumps

-

PoP (Package-on-Package): Vertical stacking (e.g., logic + memory)

-

PG-WF2BGA: Fan-out wafer-level packaging

-

Challenges: X-ray inspection (AXI), complex rework, CTE-matching PCB materials.

Array Package Comparison

| Feature | PGA (Pin Grid Array) | LGA (Land Grid Array) | BGA (Ball Grid Array) |

|---|---|---|---|

| Connection | Rigid pins | Planar contacts | Solder balls |

| Key Strength | Socket reliability | Density + socketable | Max density/min size |

| Signal Delay | Highest | Medium | Lowest |

| Applications | Legacy CPUs/industrial | Desktop/server CPUs | Mobile/GPU/SoC |

| PCB Space | Large | Medium | Compact |

Chip-Scale & Wafer-Level Packages: Approaching Physical Limits

CSP: Redefining Size Boundaries

CSP (Chip Scale Package) key metric: Package size ≤ 1.2× die size (vs. 2–5× for traditional). Essentially miniaturized BGA (FBGA/VFBGA) with finer pitch (0.2–0.5mm).

Value: Ultimate miniaturization for wearables/sensors.

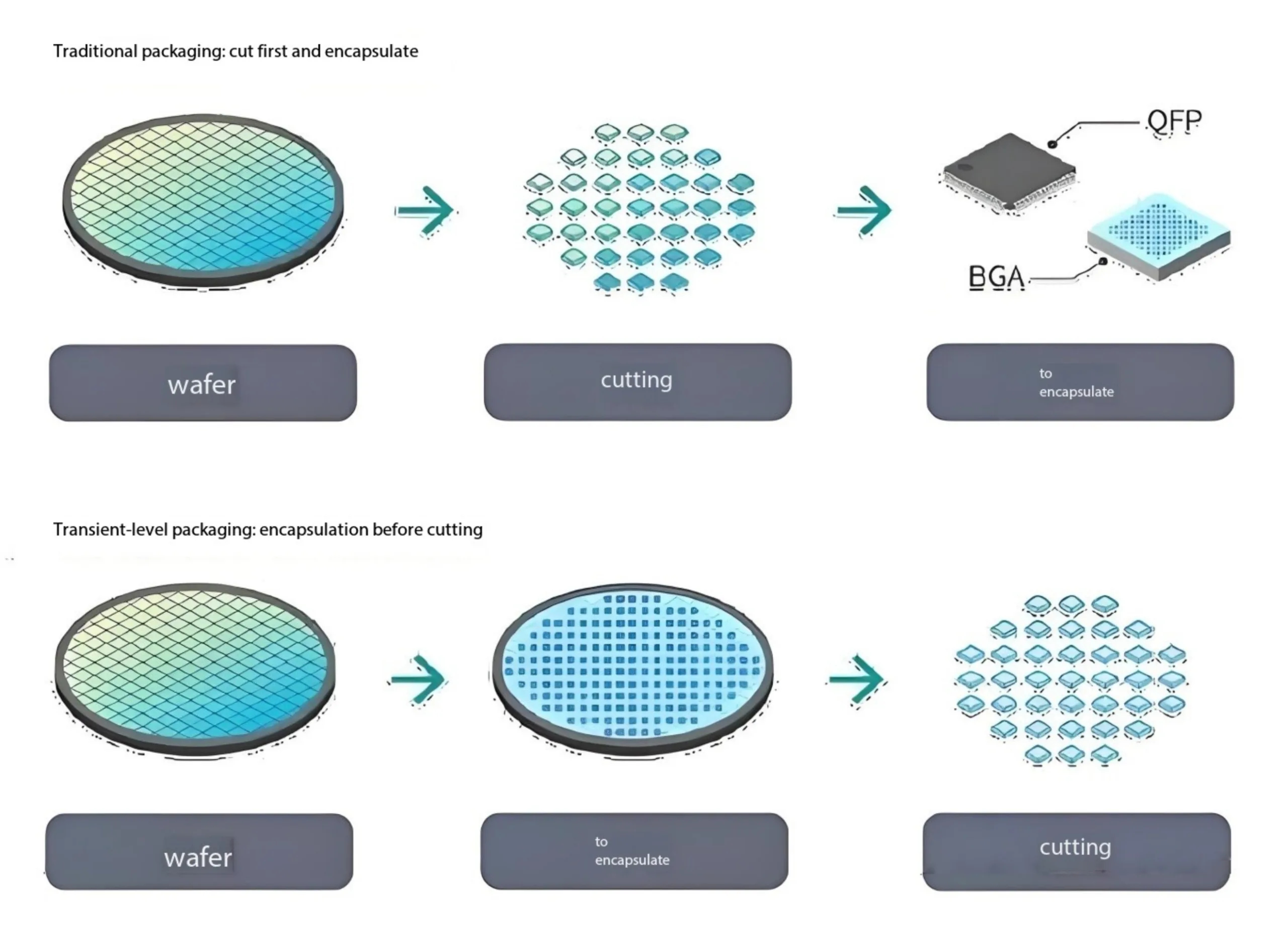

WLCSP: The Wafer-Level Revolution

WLCSP/Wafer-Level Packaging completes all steps (RDL, balling) on the wafer before dicing.

Disruptive Advantages:

-

Minimal Size: ≈ Die dimensions

-

Cost Reduction: 30-50% cheaper (no substrates/molding)

-

Peak Performance: Shortest interconnects, lowest parasitics

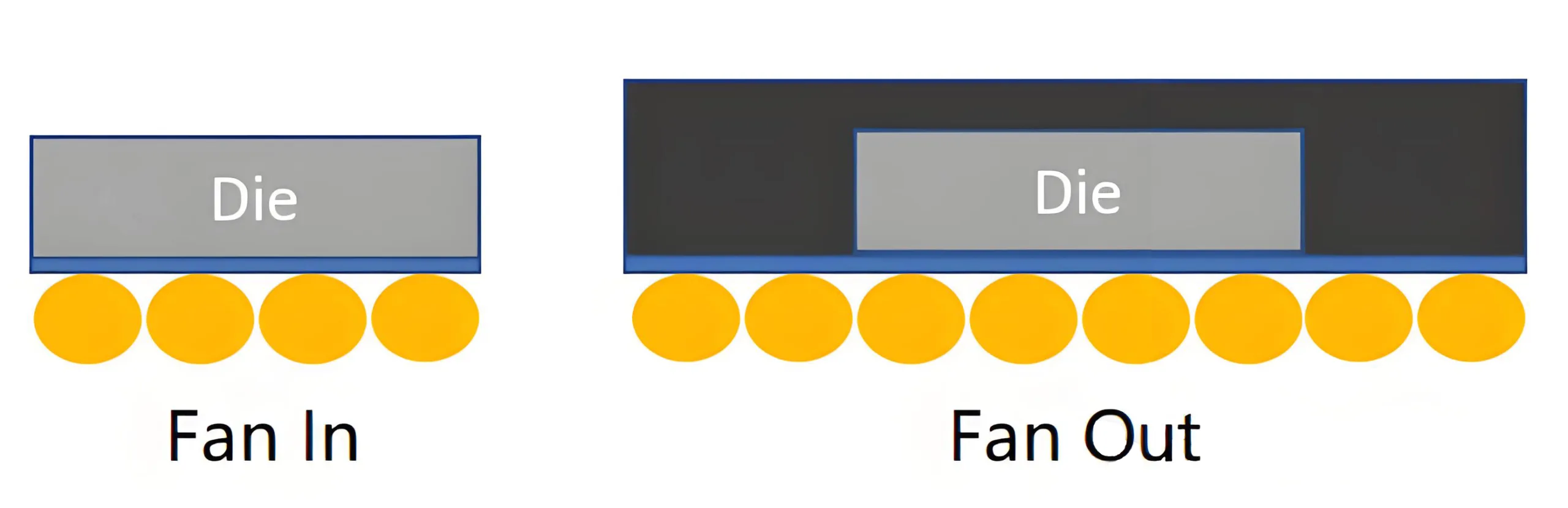

WLCSP Types:

-

Fan-In WLCSP:

-

Balls within die area

-

Package size = die size

-

Low-cost for sensors/PMICs

-

-

Fan-Out WLCSP (e.g., TSMC InFO, Samsung FO-PLP):

-

Balls extend beyond die

-

Package size > die size

-

Higher I/O density, multi-chip integration

-

For premium SoCs/RF modules

-

Visual ID: Unencapsulated silicon (vs. resin-molded DFN).

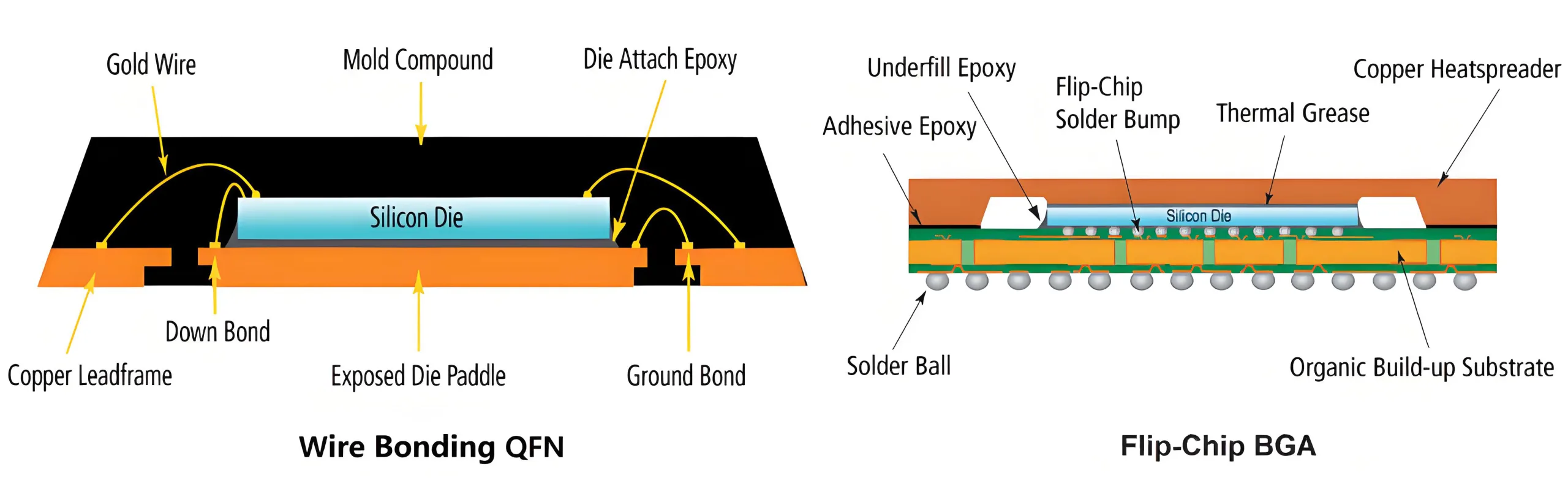

Packaging Morphology & Bonding Techniques

External package form (QFP/BGA/WLCSP) and internal bonding are intrinsically linked:

-

Wire Bonding:

-

Mature, low-cost

-

Dominates QFP/QFN/mid-range BGAs

-

Au/Cu wires; moderate I/O

-

-

Flip-Chip:

-

Dies attach face-down via microbumps

-

Shortest interconnects, lowest inductance

-

Essential for FCBGA/WLCSP/high-performance CSP

-

Conclusion & Future Frontiers

From QFP to LGA/BGA and finally CSP/WLCSP, chip packaging evolution is a chronicle of space compression, performance gains, and cost optimization. Each miniaturization leap reshapes PCB design—driving finer traces, multilayer HDI, and advanced materials.

Next Frontier: Technologies like TSV (Through-Silicon Via), SiP (System-in-Package), and 2.5D/3D IC now enable 3D heterogeneous integration, pushing PCB design into new dimensions—to be explored in our next article.

When a billion transistors fit in a grain-of-sand-sized package, electronic engineering battles at the molecular scale.

UGPCB LOGO

UGPCB LOGO

Thanks for sharing the information with us.

whoah this blog is magnificent i really like reading your articles. Keep up the good paintings! You recognize, many people are searching round for this info, you can help them greatly.