Radio signals traverse invisible airwaves, powered by RF PCBs undergoing a silent yet transformative technological evolution.

The rapid advancement of high-frequency communication is propelling RF PCB technology into a new era. Global 5G infrastructure deployment accelerates, millimeter-wave spectrum adoption expands, and IoT device proliferation grows exponentially – all demanding unprecedented performance from RF circuits.

Traditional FR-4 materials struggle with high-frequency requirements, while innovations like graphene transistors, liquid crystal polymer (LCP) substrates, and low-temperature curing adhesives are pushing physical boundaries. Concurrently, rigid-flex PCBs now achieve 100,000+ bend cycles, flexible circuits reach 0.05mm thickness, and custom-length FPC production becomes feasible – manufacturing breakthroughs enabling wearable electronics and new-energy vehicle innovations.

1. Material Revolution: Breaking High-Frequency Barriers

RF PCB performance hinges on core material properties. At millimeter-wave frequencies (>30GHz), dielectric constant (Dk) and dissipation factor (Df) become critical selection parameters determining signal transmission efficiency.

Traditional FR-4 (Dk≈4.3, Df≈0.02) exhibits significant loss above 10GHz, failing 5G/radar demands. Industry solutions now include:

-

Graphene RF Transistors: Flexible substrates now support 39GHz cutoff frequency devices. Carrier mobility reaches 2,500 cm²/V·s with <10% performance degradation after 1,000 bend cycles (IEC 60340 standard).

-

LCP Substrates: Preferred for wearables, LCP hybrid flex circuits achieve >90% transmittance and 3mm bend radius with 100,000-fold durability. Superior electrical properties (Dk=2.9-3.1, Df=0.002-0.004) outperform conventional materials.

-

Low-Temp Adhesives: Novel epoxy formulations cure at 80-120°C (30% lower than traditional processes), extending stencil life to 8,000+ prints while reducing production costs by 18%. Ideal for Mini LED packaging and automotive flex circuits.

High-Frequency PCB Material Comparison

| Material | Dk | Df | Max Frequency | Cost Factor |

|---|---|---|---|---|

| Standard FR-4 | 4.3-4.8 | 0.018-0.025 | <5GHz | 1.0x |

| Rogers 4350B | 3.48±0.05 | 0.0037 | 30GHz | 8.5x |

| PTFE-Based | 2.8-3.0 | 0.0009-0.002 | 77GHz | 12x |

| LCP | 2.9-3.1 | 0.002-0.004 | 110GHz | 15x |

| Graphene Composite | 2.3-3.5 | 0.0005-0.001 | >100GHz | 20x+ |

2. Design Breakthroughs: Redefining Density & Efficiency

Device miniaturization demands space-optimized RF PCB designs:

-

Ultra-thin flex circuits (0.05mm) increase wiring density by 50%, enabling 20% volume reduction in Tesla’s 4680 battery packs.

-

HDI rigid-flex boards achieve 20/20μm trace/space with 56Gbps throughput (e.g., Apple Vision Pro eye-tracking sensors), using laser back-drilling to control stubs <50μm.

-

Thermal management innovations: Nano-modified polyimide withstands 300°C and 1200V breakdown voltage for 800V EV platforms.

*”Rigid-flex PCBs contour to smartwatch curves, improving space utilization by 40%” – Huawei Watch GT4 Design Team*

3. Manufacturing: Precision Meets Intelligence

-

Laser Direct Imaging (LDI): Enables 5μm line widths with 92% yield, tripling traditional exposure efficiency.

-

Stepwise Processing: Combines die-cutting with laser etching for ±2μm dimensional accuracy (01005 component compatible).

-

AI Visual Inspection: 99.9% defect recognition for micron-level flaws, enhancing reliability while reducing costs.

4. Applications: Wearables to Electric Vehicles

Wearable Technology

Rigid-flex PCBs dominate the $150B wearable market:

-

Lululemon yoga pants with pressure-sensing flex PCBs

-

Apple Watch Ultra ECG connections (500Mbps data rate)

-

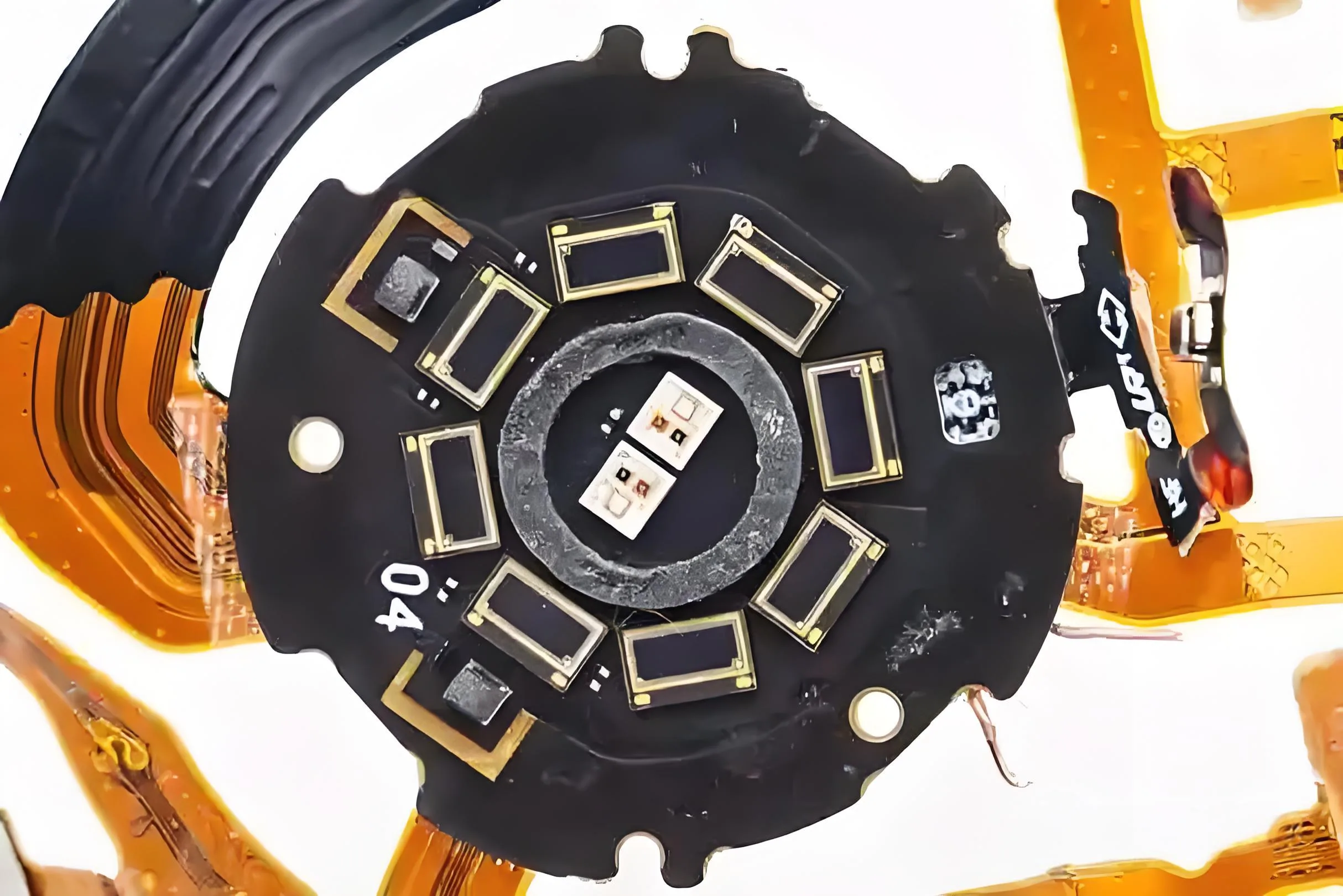

Meta Quest 4 HDI boards integrating 12 cameras + 5 mmWave radars

EV Electronics

BYD’s automotive flex solutions:

-

BMS FPCs with 100k cell monitoring/sec

-

Steering wheel ECG modules (95% accuracy)

-

THz-ready circuits for 6G V2X (0.1ms latency target)

High-Frequency Systems

Graphene RF transistors enable 39GHz 5G/6G base stations. Conductive inks reduce skin effect, while graphene-copper composites enhance corrosion resistance.

5. Future Trends: Convergence & Advancement

-

Embedded Components (IPD): 01005 component integration shrinks board size 40% while improving signal integrity.

-

Self-Powered Systems: Triboelectric nanogenerators (TENG) harvest kinetic energy; Neuralink-style brain interfaces enable thought-controlled vehicles.

-

Sustainable Manufacturing: Water-based inks and lead-free soldering reduce waste by 40%. Copper recycling rates >95% support “Zero-Carbon FPC” goals by 2030.

*Materials scientists predict: “Graphene-liquid metal composites will breach 100GHz barriers for 6G physical layers.”*

6. Conclusion

RF PCB advancements span materials (graphene/LCP), design (3D integration), and manufacturing (AI/LDI). These innovations drive 5G infrastructure, wearable devices, and EV performance.

With expanding 5G/mmWave deployments and IoT growth, demand for high-frequency PCB suppliers will intensify. Industry leaders like UGPCB continue developing patented solutions in advanced materials and flexible circuit technologies.

UGPCB LOGO

UGPCB LOGO