The Life-or-Death Battle in Microelectronics: Solder Mask Gap-Induced Chain Reaction

With 0201 components and 0.3mm pitch BGAs becoming mainstream, PCB pad solder skipping rates have surged 37% (IPC 2023 data). According to a decade-long study by UGPCB: 60% of SMT defects originate from paste transfer failure, where micro pad printing gaps act as the overlooked “invisible killer”.

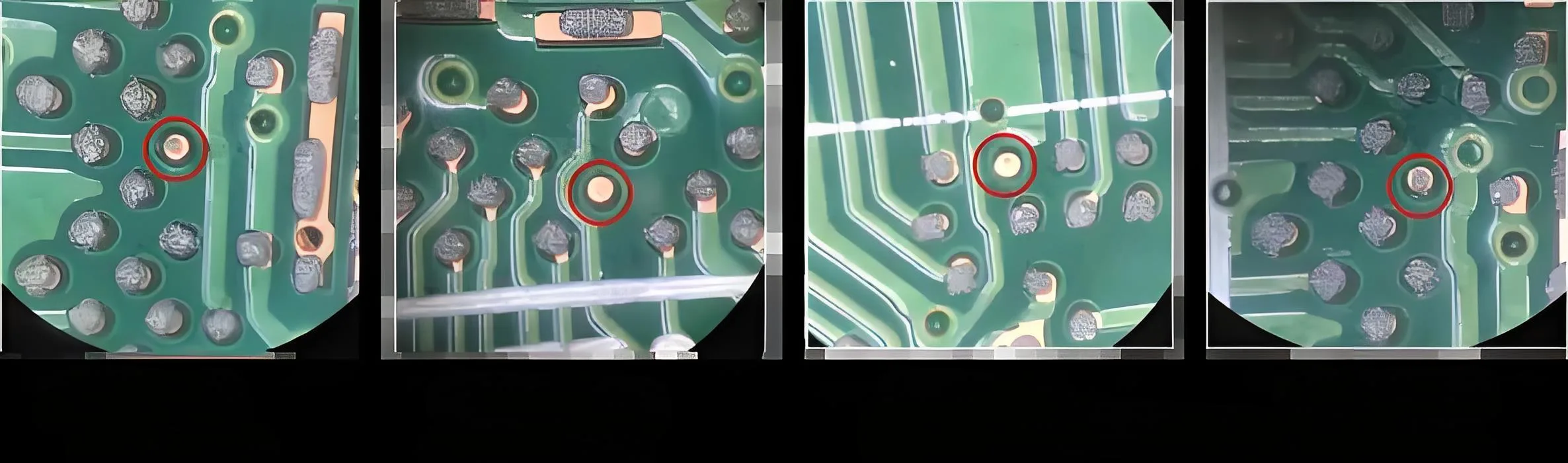

Lessons Written in Blood: Micrograph Reveals Industry Pain Points

-

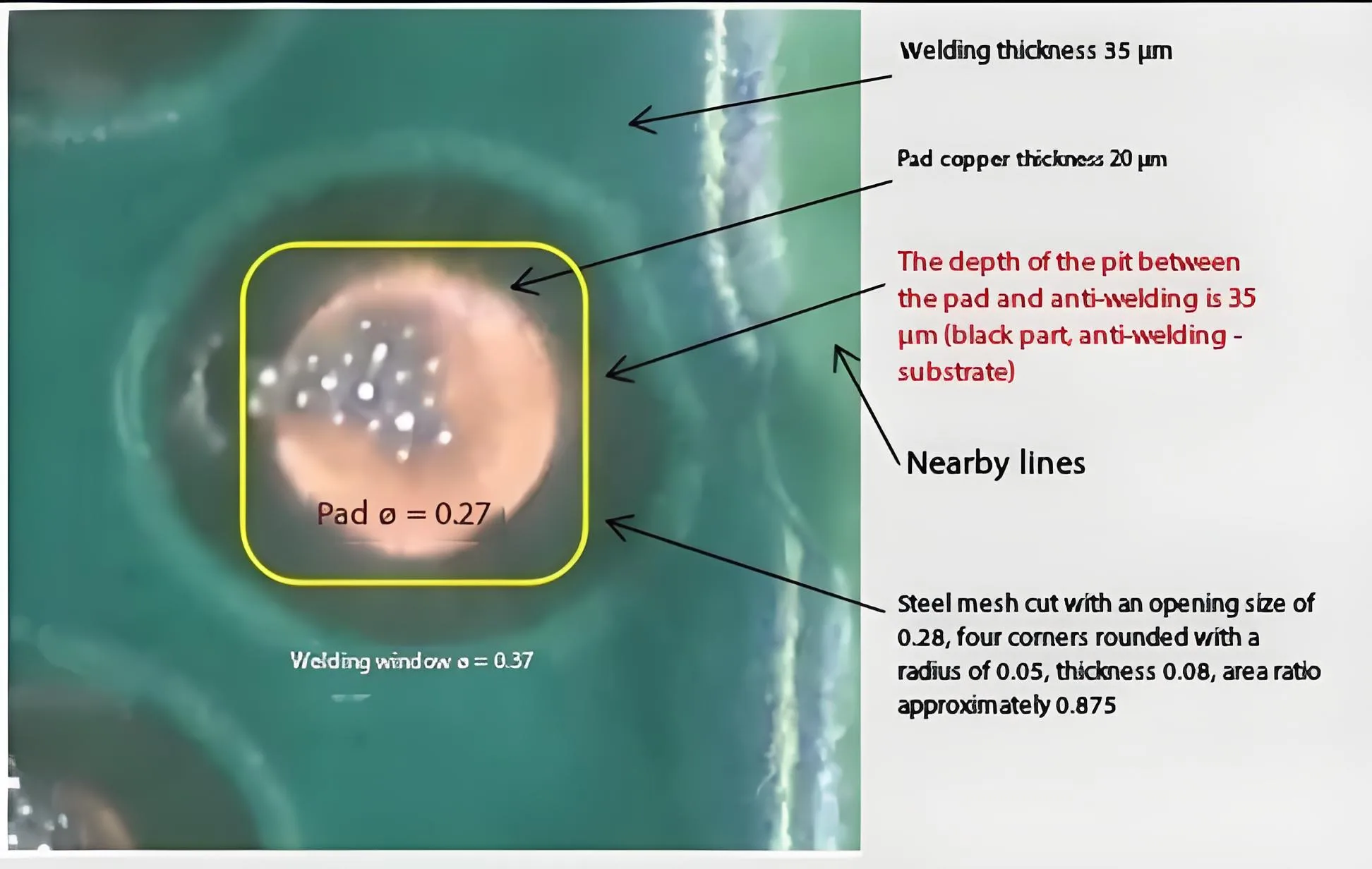

Solder mask to copper pad height difference: 35μm

-

Stencil aperture covering substrate area: 42%

-

Effective solder paste contact area: <58%

Physics Behind Failure: The Mathematical “Death Triangle” of Paste Transfer

Fatal Formula: The Collapse of IPC-7525 Area Ratio Theory

Area Ratio = (L×W) / [2h(L+W)]

Traditional theory fails when pad diameter ≤0.3mm! Empirical data from leading manufacturers reveals:

| Pad Diameter (mm) | Theoretical Area Ratio | Actual Transfer Rate |

|---|---|---|

| 0.40 | 0.68 | 92% |

| 0.31 | 0.61 | 85% |

| 0.27 | 0.55 | 63% |

Fluid Dynamics Exposed: Why Solder Paste “Rejects” Pads

Figure 2: Fluid Tension Simulation During Stencil Release

Alt: Solder paste stencil wall tension analysis – PCBA printing defect simulation – SMT solutions

Critical Findings:

-

Solder mask gaps create air cushion effect, reducing contact area by 41%

-

Solder skip occurs when paste cohesion > pad adhesion

Industrial-Grade Solutions: Three Pillars to Eliminate Solder Skipping

Pad Design Revolution: Copper Expansion Principle

-

Isolated pad diameter: 0.27mm → 0.31mm

-

Gap coverage reduced to 12%

-

Transfer rate increased to 89% (empirical data)

Solder Mask “Slimming” Initiative: The 25μm Gold Standard

Figure 3: Printing Comparison with Different Solder Mask Thicknesses

Alt: PCB solder mask thickness comparison – SMT yield improvement – PCBA supplier guide

Thickness Formula: H = (Rz + δ) × K (δ = paste particle size, Type 4: 25μm; K = safety factor 1.2)

Industry Validation: Mobile PCB manufacturer reduced thickness from 35μm to 22μm → 82% reduction in QFN solder skip

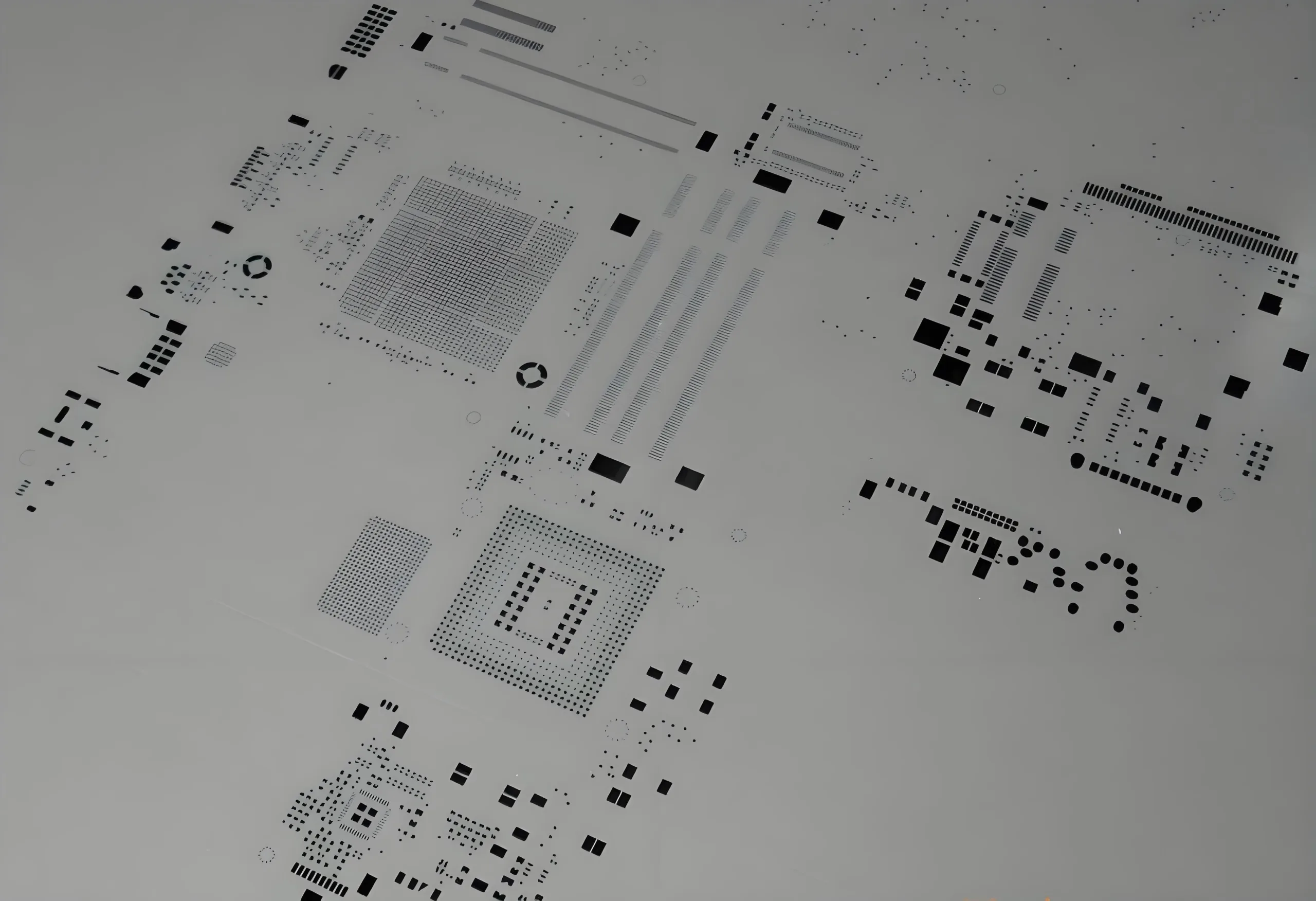

PH Stencils: The Ultimate Nano-Conformity Solution

Innovations:

Innovations:

-

Stepped aperture design: Wall angle from 7° to 15°

-

Electroformed nickel: 3x hardness increase

-

Demolding assist angle: 40% reduced wall friction

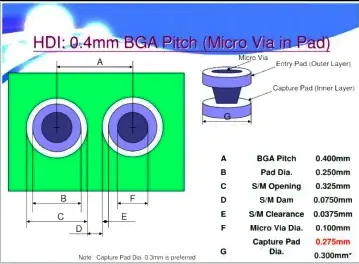

Industry Leaders’ Playbook: HDI + NSMD Gold Standard

Mobile Industry’s Precision Strategy

Case: 0.4mm Pitch BGA Process Blueprint 1. Replace legend printing → Bare copper design 2. Implement HDI microvias 3. Solder mask thickness: 18±3μm (IPC-6012 Class 3 compliant)

Conversion Engine: Your Factory Upgrade Action Plan

Immediate Execution Checklist:

-

Audit all isolated pads: Redesign if diameter <0.3mm

-

Demand solder mask thickness reports from PCB suppliers (Key metric: ≤25μm)

-

Procure PH stencils urgently: 55% aperture efficiency gain in fine-pitch areas

UGPCB LOGO

UGPCB LOGO