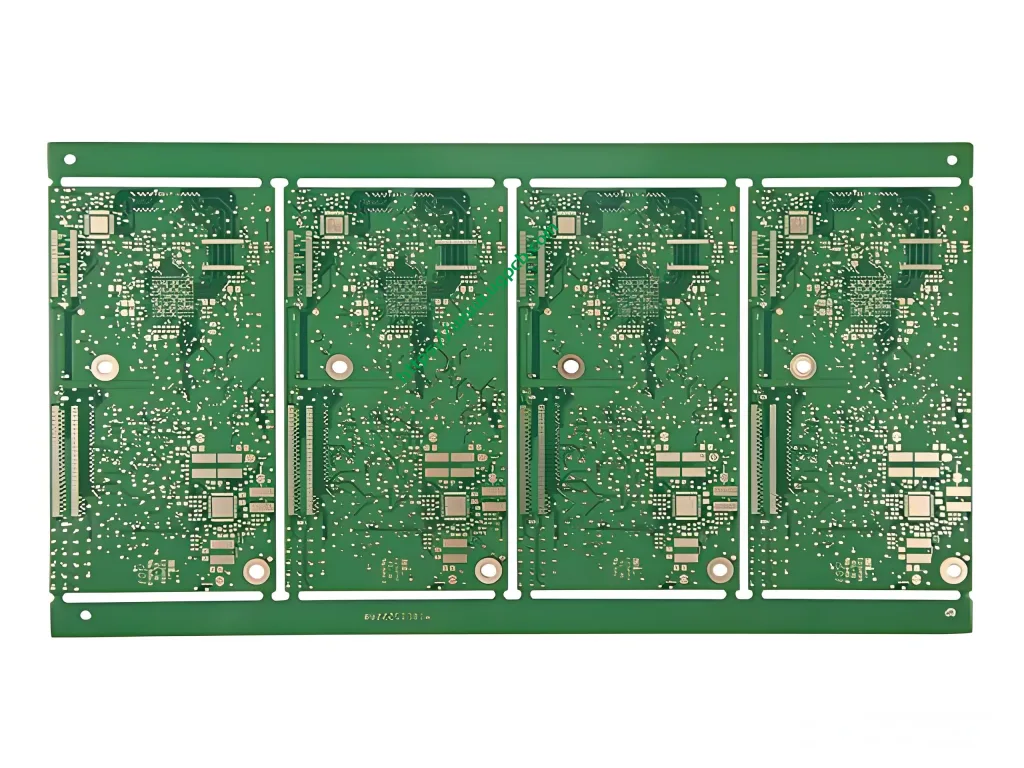

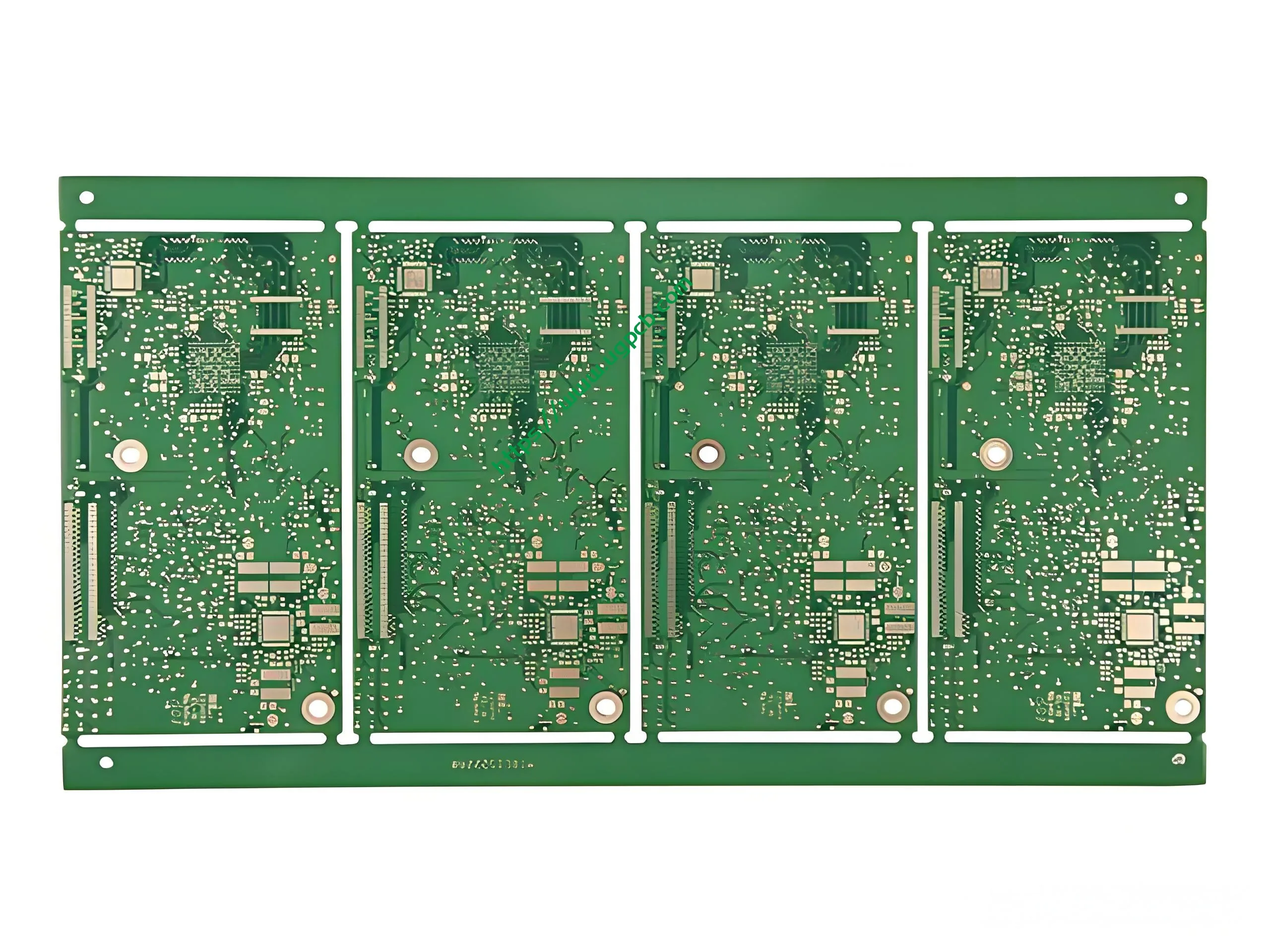

UGPCB’s 8-Layer 1+N+1 HDI PCB: A Comprehensive Guide

In the relentless pursuit of miniaturization and enhanced performance in electronics, High-Density Interconnect (HDI) PCBs have become the cornerstone. UGPCB’s 8-Layer 1+N+1 HDI product represents a sophisticated solution for designers pushing the boundaries of what’s possible. This article provides a detailed look at this advanced printed circuit board technology.

What is an 8-Layer 1+N+1 HDI PCB?

An 8-Layer 1+N+1 HDI PCB is a specific type of high-density interconnect board. The nomenclature “1+N+1” describes its microvia build-up structure.

-

The First and Last ‘1’: These represent a single layer of high-density microvias on the top and bottom surfaces of the board. These microvias are typically created using laser drilling.

-

The ‘N’: This represents the core of the board, which in this case is a standard 6-layer multilayer PCB (making the total 8 layers). The core contains through-holes or buried vias that connect the internal layers.

This structure allows for a very high number of interconnections in a compact space, making it ideal for complex, space-constrained PCB designs essential for modern microelectronic products.

Key Design Features and Specifications

UGPCB manufactures this HDI PCB with precision, adhering to the following critical specifications:

-

Material: High-Tg FR-4, a robust and reliable laminate offering excellent thermal and mechanical stability.

-

Board Thickness: A finished thickness of 0.8mm, supporting slim product profiles.

-

Copper Weight: 1 oz (35µm) for inner layers and 0.5 oz (17.5µm) for outer layers. This balance ensures good current carrying capacity while allowing for finer outer layer trace etching.

-

Surface Finish: Immersion Gold (ENIG) over an OSP (Organic Solderability Preservative) foundation. This combination provides a flat, durable surface for soldering and excellent shelf life.

-

Minimum Trace/Space: 3 mil (0.075 mm), enabling high-density circuitry.

-

Minimum Hole Size: 0.2mm for mechanical drills and an ultra-fine 0.1mm for laser-drilled microvias.

How This HDI PCB Structure Works

The “1+N+1” architecture functions by creating a more efficient routing pathway. Instead of using large through-holes that consume valuable real estate on every layer, this HDI PCB design utilizes microvias. These tiny laser-drilled holes connect only adjacent layers (e.g., L1 to L2, or L8 to L7). This “stacked” or “staggered” via approach frees up routing channels on the inner layers, allowing for a much greater component density and more efficient signal paths, which is crucial for high-speed PCBA assembly.

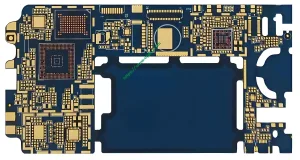

Primary Applications and Use Cases

The primary application for this advanced HDI PCB is in sophisticated microelectronic products. Specific use cases include:

-

Wearable Technology: Smartwatches, fitness trackers, and medical monitors.

-

Advanced Mobile Devices: Smartphones, tablets, and ultra-portable laptops.

-

High-Density Medical Equipment: Miniaturized medical imaging and diagnostic devices.

-

Aerospace and Defense Avionics: Where reliability and size are paramount.

The Material Composition: FR-4 Laminate

The choice of FR-4 material is strategic. It provides an excellent balance of performance, cost, and manufacturability. For this 0.8mm thick HDI PCB, a high-grade FR-4 with a high glass transition temperature (Tg) is used to withstand the thermal stress of multiple lamination cycles and lead-free PCBA soldering processes.

Performance and Structural Advantages

The structure of the 1+N+1 HDI board directly translates to significant performance benefits:

-

Enhanced Signal Integrity: Shorter interconnection paths reduce signal loss and propagation delay.

-

Improved Thermal Management: The dense via structure aids in heat dissipation.

-

Superior Reliability: The use of microvias reduces the risk of solder joint failure during thermal cycling.

-

Reduced Size and Weight: The core advantage of HDI technology, enabling smaller end products.

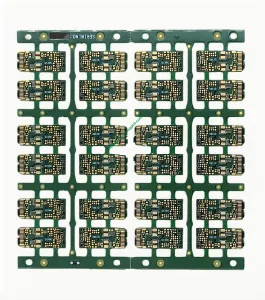

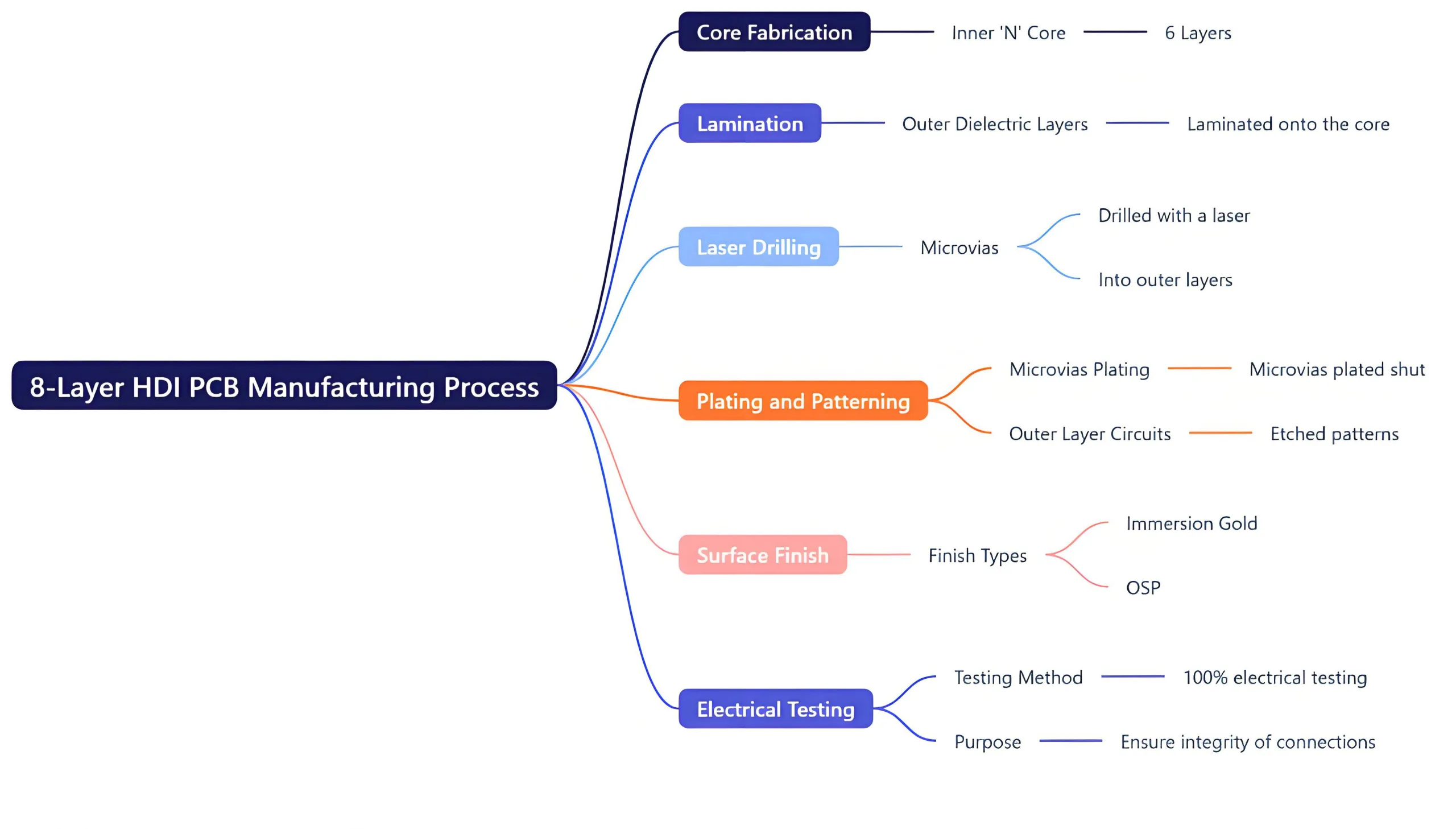

A Simplified Overview of the Production Process

The manufacturing of this HDI PCB is a multi-step, precision process:

-

Core Fabrication: The inner ‘N’ core (6 layers) is produced first.

-

Lamination: Outer dielectric layers are laminated onto the core.

-

Laser Drilling: Microvias are drilled with a laser into the outer layers.

-

Plating and Patterning: The microvias are plated shut, and the outer layer circuits are etched.

-

Surface Finish: The Immersion Gold and OSP are applied.

-

Electrical Testing: 100% electrical testing ensures the integrity of all connections.

Why Choose UGPCB for Your HDI PCB and PCBA Needs?

UGPCB’s expertise in manufacturing 8-Layer HDI PCBs offers distinct advantages for your project. Their capability to reliably produce boards with 3/3 mil lines and 0.1mm microvias positions them as a leader for complex PCB manufacturing. This makes them an ideal partner not just for PCB fabrication but also for a full turnkey PCBA service, ensuring a seamless transition from design to a finished, assembled product.

UGPCB LOGO

UGPCB LOGO