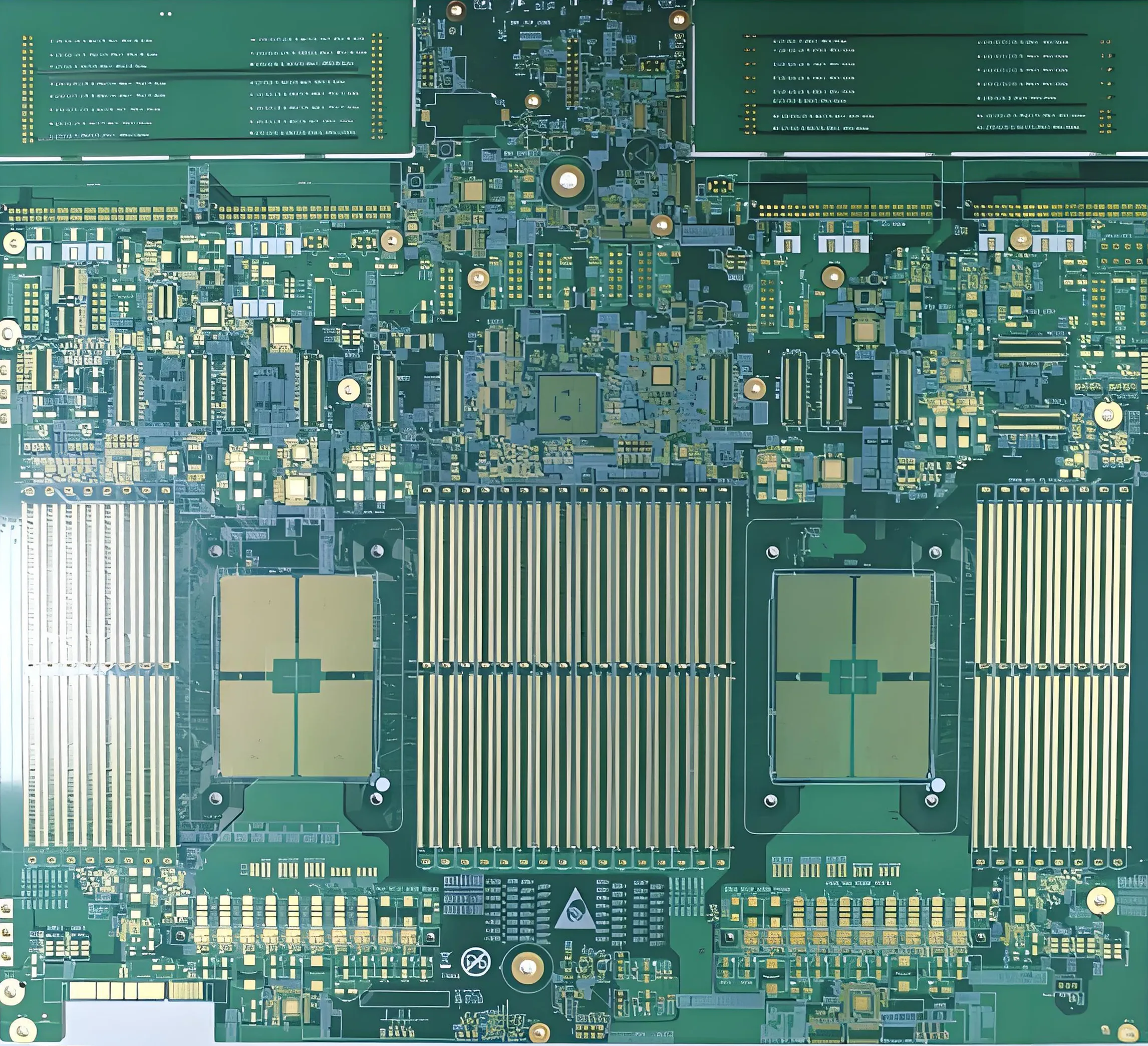

Power the Future of Computing: UGPCB’s High-Performance Server PCB Solutions

In today’s rapidly evolving landscape of data centers, artificial intelligence, and cloud computing, server performance and stability are pivotal to digital efficiency. As the fundamental hardware bedrock, the quality of Server Printed Circuit Boards (PCBs) is paramount. Leveraging deep technical expertise, UGPCB provides professional, customized, high-performance server PCB manufacturing and PCBA (Printed Circuit Board Assembly) one-stop solutions.

1. Product Overview & Definition

A Server PCB is a complex, multi-layer circuit board specifically engineered for server-class products. Its critical mission is to host core components like CPUs, memory, high-speed buses, and power modules while ensuring stable signal transmission at speeds of tens of Gbps and beyond. It is not merely a physical connection platform but the core element guaranteeing the system’s signal integrity, power integrity, and thermal performance.

The specifications you provide (Board Thickness: 2.8mm ±10%, 22 Layers, 2/1 oz Copper Weight, 0.1/0.1 mm Trace/Space) define a typical high-layer-count, high-density, high-speed server PCB. It is suitable for critical applications in mid-to-high-end dual-processor or AI server motherboards, accelerator cards, and backplanes.

2. Design Essentials & Key Technologies

The success of such advanced PCB designs hinges on mastering a range of cutting-edge technologies:

-

Stack-up & Impedance Control: The complex 22-layer stack-up requires precise calculation to achieve strict impedance control (typically 50Ω single-ended, 100Ω differential), forming the cornerstone of high-speed PCB design.

-

Back Drilling: This critical process removes the unused copper stub from high-speed signal vias (e.g., for PCIe, DDR buses), significantly reducing signal reflection and attenuation, and is central to enhancing signal integrity.

-

High-Speed Laminate Application: We utilize premium high-speed materials like IT-968G & IT-180A from ITEQ. Their low dissipation factor (Df) and stable dielectric constant (Dk) ensure signal purity and low latency. A high Glass Transition Temperature (Tg >170°C) guarantees material reliability under the prolonged high-temperature operation of servers.

-

RTF (Reverse Treated Foil) Copper: Its smoother surface profile effectively reduces “skin effect” losses for high-frequency signals on the conductor surface, further enhancing high-speed performance.

-

Any-Layer HDI & Hybrid Construction: Supports high-density routing. Combined with hybrid construction techniques, it allows the use of different performance materials in localized areas (e.g., high-current power zones vs. high-speed signal zones) to meet specific circuit requirements.

3. Performance & Structural Features

-

Exceptional Electrical Performance: Extremely low signal loss and excellent impedance consistency meet the demands of high-speed protocols like PCIe 4.0/5.0 and DDR4/DDR5.

-

Ultra-High Reliability: ENIG (Electroless Nickel Immersion Gold) surface finish provides a flat soldering surface and superior oxidation resistance, ensuring long-term connection reliability. The 10oz thick inner copper cores (combined with the 2/1oz design) offer robust current-carrying capacity and thermal pathways for power layers.

-

Precision Manufacturing Capability: The 0.1/0.1 mm trace/space and a minimum finished hole diameter of 0.25mm demonstrate UGPCB’s top-tier expertise in high-precision PCB fabrication.

-

Robust Thermal Management: The 2.8mm thick board structure, combined with thick copper design, provides excellent thermal dissipation, aiding overall system cooling.

4. Production Process & Quality Control

UGPCB’s server PCB production follows a stringent, automotive electronics-grade quality control protocol: Material Inspection → Inner Layer Imaging → Precision Lamination → Laser/Mechanical Drilling → Back Drilling → Copper Deposition & Plating → Outer Layer Imaging → Solder Mask → Surface Finish (ENIG) → Electrical Test (Flying Probe/Dedicated Fixture) → Final Inspection. Each stage is supported by high-speed signal testing, AOI (Automated Optical Inspection), and more, ensuring every delivered PCB meets design specifications.

5. Application Scenarios & Technical Classification

This high-performance server PCB is widely used in:

-

AI Servers & GPU Accelerator Cards: For processing massive parallel computing tasks.

-

Cloud Computing Data Center Servers: As core compute nodes.

-

High-End Storage Servers: For high-speed data storage and exchange.

-

Network Switching Equipment: Core routing and switching motherboards.

Scientific Classification:

-

By Layer Count: High Multi-layer Board (22 Layers)

-

By Technology: High-Speed/High-Frequency PCB, Back-Drilled PCB, Heavy Copper PCB, High-Density Interconnect (HDI) PCB

-

By Application: Data Center/Server-Dedicated PCB