TG150 PCB Circuit Board Introducere: Meeting the Thermal Challenge in Modern Electronics

In high-speed communications, auto, aerospațial, and advanced industrial controls, electronic devices face increasingly harsh operating environments. Elevated temperatures can cause standard PCB substrates (De ex., standard FR-4) to reach their glass transition, leading to softening, deformation, and critical performance loss, jeopardizing system reliability. Selecting a high-Tg printed circuit board is essential for ensuring long-term stability in these demanding applications.

1. Product Overview: What is a TG150 PCB?

O TG150 PCB is a printed circuit board fabricated using a laminate material with a glass transition temperature (TG) of 150°C. The Tg is a crucial metric for a PCB substrate’s thermal endurance. Compared to common TG130 PCB laminates, TG150 material maintains superior physical rigidity and stable electrical properties under high temperatures. UGPCB 4-layer TG150 circuit board combines this high-performance material with an Aur de imersiune (De acord) surface finish and supports 0.08mm fine-line circuitry şi 0.2mm micro-drilling, making it a high-reliability PCB multistrat solution for advanced applications.

2. Core Material and Enhanced Performance of TG150 PCB

-

Material de bază: A high-performance epoxy or modified FR-4 formulation, specially engineered to consistently achieve a Tg of 150°C or higher.

-

Key Performance Advantages (vs. TG130 PCBs):

-

Exceptional Thermal Stability: The increase from 130°C to 150°C Tg significantly enhances the board’s resistance to deformation at high temperatures, improving its ability to withstand high-temperature assembly processes like lead-free soldering.

-

Superior Moisture and Chemical Resistance: A denser molecular structure reduces moisture absorption in humid environments, minimizing losses in insulation resistance (IR) și integritatea semnalului, while offering better resistance to chemical exposure.

-

Improved Mechanical Strength and Dimensional Stability: High Tg PCBs exhibit lower Z-axis expansion coefficients and stronger bond strength during thermal cycling, reducing risks like via cracking and delamination.

-

Stable Electrical Characteristics: Constanta dielectrică (DK) şi factor de disipare (Df) remain more stable at elevated operating temperatures, ensuring higher signal integrity for PCB-uri de înaltă frecvență.

-

3. Structure and Design Specifications of Our TG150 PCB

PCB Stack-up

This product is a standard 4-strat PCB board. A typical stack-up is Signal Layer – Ground Plane – Power Plane – Signal Layer, providing a complete return path for high-speed signals and effective EMI control.

Key Design Capabilities & Specifications

Minimum Trace Width/Space: 0.08mm / 0.1mm. This represents advanced fine-line Fabricarea PCB-urilor capability, essential for routing high-density ICs (De ex., BGA packages).

Drill Diameter: 0.2mm. Suport micro-via drilling, facilitating higher density interconnects and saving board space.

Surface Finish: Aur de imersiune (De acord). Provides a flat surface, excellent solderability, and long shelf life, ideal for fine-pitch components (De ex., MFF, BGA).

4. Manufacturing Process and Quality Control

UGPCB TG150 PCB manufacturing process strictly adheres to international standards like IPC-6012 (Qualification and Performance Specification for Rigid PCBs). The process includes:

Material Preparation → Inner Layer Imaging → Etching → Lamination → Drilling (0.2mm) → Desmear & Plating → Outer Layer Imaging → Pattern Plating → Etching → Solder Mask Application → ENIG Surface Finish → Routing → Electrical Testing → Final Inspection.

At each stage, we employ advanced equipment (De ex., LDI imaging, AOI inspection) and rigorous reliability testing (De ex., stres termic, ionic contamination) to ensure the quality of every high-Tg circuit board.

5. Product Classification and Typical Applications

-

Technical Classification:

-

By Tg: Mid-High Tg PCB (Tg ≥ 150°C).

-

By Layer Count: PCB multistrat (4-Layer Board).

-

Prin tehnologie: Precision PCB (HDI-ready capability).

-

By Finish: ENIG PCB, Fine-Line PCB.

-

-

Ideal Application Scenarios:

-

Electronică auto: Unități de control al motorului (ACOPERI), infotainment systems, power management modules – requiring tolerance under-hood temperatures.

-

Telecommunications Equipment: 5G base station PAs, optical modules, network switches – where high power generates sustained heat.

-

Industrial Controls: Servo drives, PLCs, industrial PCs – for reliable operation in hot factory environments.

-

Power Electronics: High-power switch-mode power supplies (SMPS), inverters – where power components generate significant heat.

-

Aerospațial & Defense: Electronic systems with extreme demands for reliability and environmental resilience.

-

6. Why Choose UGPCB for Your TG150 PCBs?

-

Certified Materials: We use verified, traceable TG150 PCB laminates from reputable suppliers.

-

Precision Manufacturing: Our expertise in multilayer PCB fabrication şi ENIG processing ensures high yield for 0.08mm fine-line designs.

-

Guaranteed Specifications: All technical parameters (Tg 150°C, 0.2mm drills) are rigorously validated against datasheets.

-

End-to-End Support: We provide full technical support from Design PCB recenzie şi controlul impedanței to rapid prototyping and volume production.

7. Take Action: Secure Your Design with a Robust Foundation

Don’t let thermal limitations hinder your product innovation. Choosing UGPCB’s high-reliability TG150 PCB means investing in exceptional stability, durability, și performanță.

Apel la acțiune

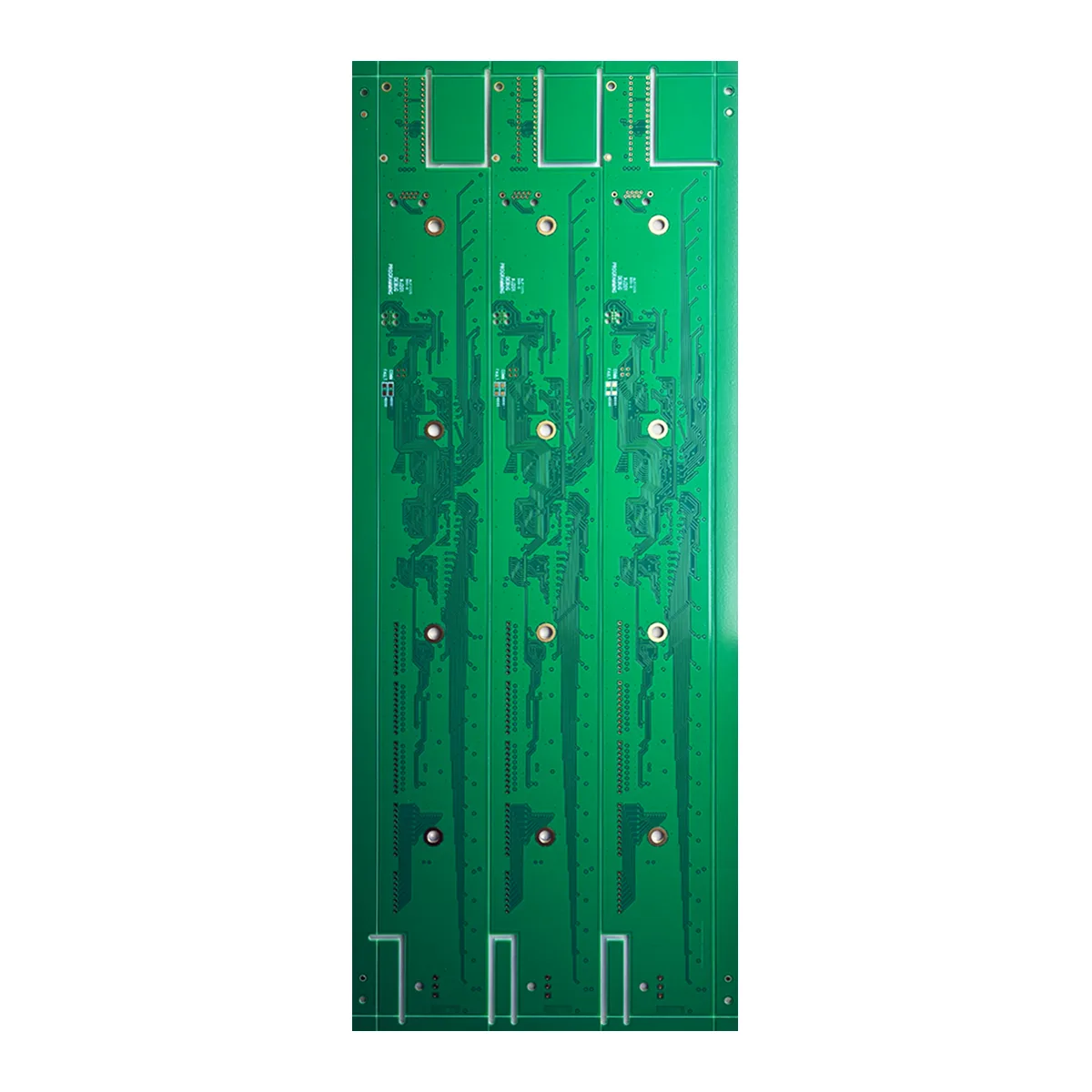

*(Image Suggestion: High-quality close-up photo of a populated TG150 PCB used in a telecom orautomotive application.)*

Alt Tag: High-density assembled 4-layer TG150 PCB with ENIG finish for automotive or telecom applications

Is your next project facing thermal reliability challenges?

Do you need a PCB that can withstand rigorous environmental stress?

Contact the UGPCB expert team today!

[Click here to Get a Free Quote for TG150 PCBs]

[Upload Your Gerber Files for a 24-Hour Design Review]

Let our expertise in high-performance Fabricarea PCB-urilor power your success.