Professional Definition: What is a 6-Layer High-Frequency Hybrid PCB?

In the fields of 5G communications, Автомобильный радар, and high-end computing, стандартный FR-4 PCBs often fall short in meeting the demands for high-frequency, высокоскоростной, and high-stability signal transmission. This is where the Высокочастотный Гибридная печатная плата becomes critical.

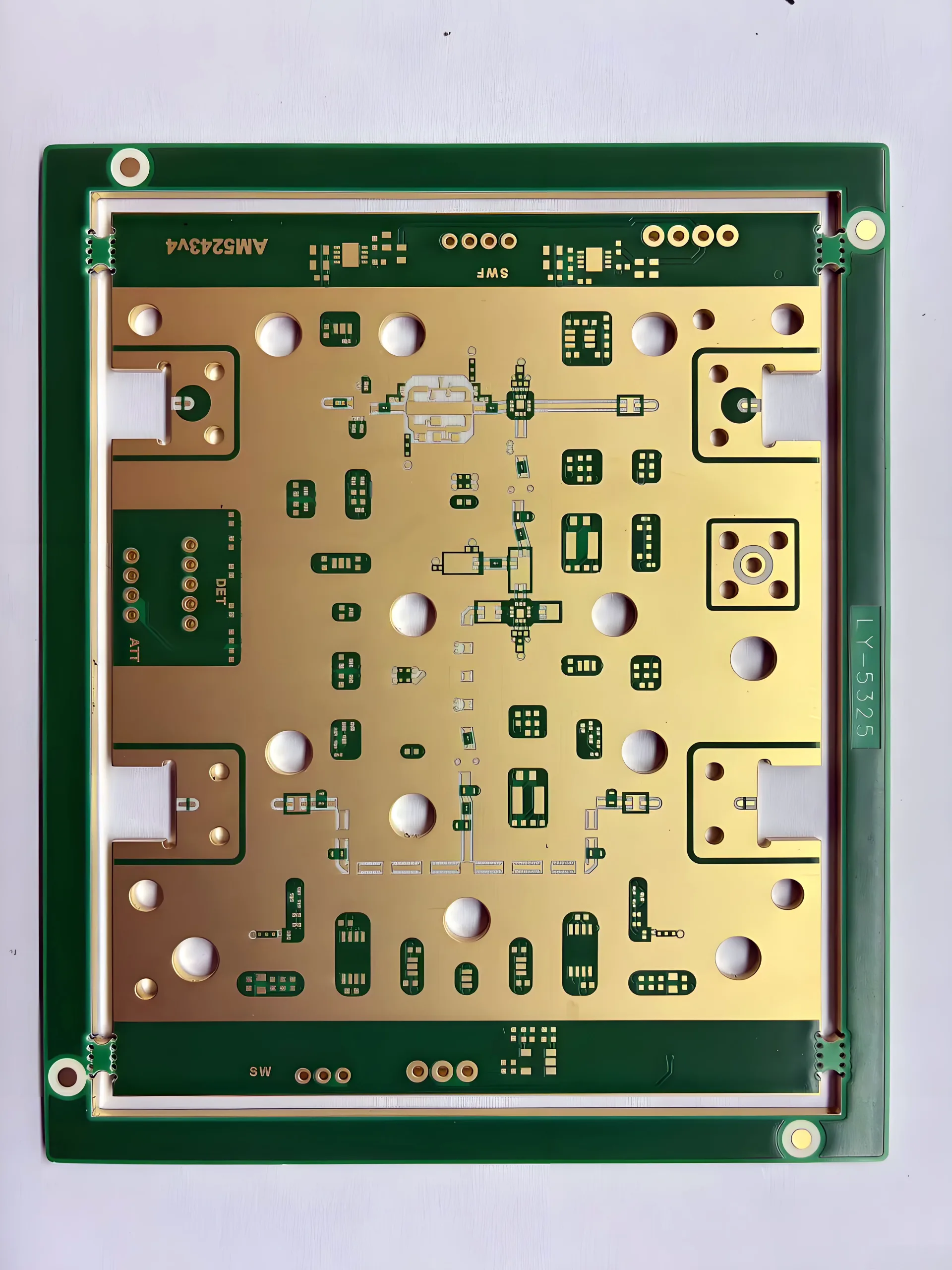

A 6-layer high-frequency hybrid PCB is a multilayer circuit board that integrates different performance-grade high-frequency laminate материалы (such as Rogers) with standard or specialized materials through precision lamination. Этот hybrid construction strategically places materials to optimize electrical, тепло, and cost performance across different circuit layers. It serves as the core hardware foundation for complex RF microwave circuits and high-speed digital designs.

Product Deep Dive: UGPCB’s High-Performance 6-Layer Hybrid Board

1. Основные спецификации & Материальная наука

-

Слой & Строительство: 6 Слои. This represents an optimal balance between complexity, производительность, и стоимость, suitable for integrating digital control and RF front-end circuits.

-

Material Stack-up (Hybrid Core):

Rogers 4350B + Rogers 4450F + IT180A. This is the essence of the design.-

Роджерс 4350b: An industry-standard high-frequency circuit board material known for its stable Диэлектрическая проницаемость (Дк) and low Коэффициент рассеяния (Дф), making it ideal for RF signal layers.

-

Rogers 4450F: A prepreg (ПП) with high glass transition temperature (Тг) and excellent thermal stability, used for bonding layers and ensuring reliability of the hybrid stack-up under thermal stress.

-

ИТ180А: A high-performance, mid-loss thermoset material often used for inner signal or power plane layers where good signal integrity is required at a managed cost. This hybrid approach applies the best material where it’s needed most.

-

-

Толщина & Медный вес: Стандартный 1.6мм thickness for good mechanical rigidity. Copper weight is

1/H/H/H/H/1 oz, indicating 1 oz copper foil for outer layers и 0.5 унция (H oz) copper for inner layers. This facilitates fine-line etching and optimized impedance control. -

Поверхностная отделка: Электролетное никелевое электролетное погружение палладий Золото (Enepic): 120 μin Ni, 2 μin Pd, 2 μin Au. This is a premium finish offering excellent solderability, wire-bond capability, and corrosion resistance. It is particularly suited for Подложки ИС and assemblies requiring multiple reflow cycles or gold wire bonding.

2. Соображения дизайна & Operational Principle

-

Соображения дизайна:

-

Контроль импеданса & Целостность сигнала: Utilizing the stable Dk of Rogers materials, combined with precise stack-up design and trace width/spacing control, enables tight PCB impedance control (например, 50Ω single-ended, 100Ω differential), что имеет решающее значение для high-speed PCB signal integrity.

-

Stack-up Planning: High-speed RF traces are typically routed on the Rogers material layers, while power, ground, and lower-frequency digital signals are placed on IT180A layers. A symmetrical stack-up (as in this design) helps prevent warpage.

-

Тепловое управление: The superior thermal conductivity of Rogers materials, combined with strategic ground vias and thermal relief designs, aids in dissipating heat from high-power RF components.

-

-

Operational Principle: This PCB acts as the “skeleton” and “highway system” of an electronic device. Its core function is to mount and interconnect components (RF chips, процессоры, конденсаторы, и т. д.). High-frequency signals travel via микроволновая печатная плата transmission lines on the Rogers layers with minimal loss and distortion; power is distributed stably through inner-layer copper planes; and complex interconnections are achieved via blind and buried vias, shortening paths and enhancing electrical performance.

3. Four Advanced Processes: Ensuring Reliability & Производительность

-

Основные слепые/скрытые переходные отверстия: These vias connect adjacent layers within a core (например, Rogers laminate) without penetrating the entire board. This significantly increases routing density in Взаимодействие высокой плотности (ИЧР) печатные платы, reduces parasitic effects, and improves high-frequency performance.

-

Resin Filled Vias: After plating, through-holes or blind/buried vias are filled with epoxy resin. This prevents chemical entrapment, provides a flat surface for fine-line patterning of subsequent layers, and enhances via reliability.

-

Via-in-Pad (VIP): A via is placed directly within a component pad, then filled and planarized with resin and copper. This is a hallmark of advanced HDI PCBS, enabling further miniaturization and higher component density.

-

Metalized Edge (Edge Plating): A continuous metal layer (обычно медь) is plated along the board edge. This provides excellent EMI shielding, protects internal circuits, and strengthens the edge for connector mating and mechanical wear.

4. Key Performance Characteristics

-

Superior High-Frequency Performance: Низкая потеря, stable Dk for pristine signal transmission in RF PCB.

-

Отличная целостность сигнала: Precision impedance control meets Высокоскоростной дизайн печатной платы требования.

-

Взаимодействие высокой плотности (ИЧР): Blind/buried vias and VIP technology support Высокая печатная плата layouts.

-

Повышенная надежность: Robust hybrid construction, ENEPIG finish, and metalized edges suit demanding environments.

-

Improved Thermal & Shielding Performance: Good thermal conductivity and effective EMI suppression.

5. Scientific Classification

-

По количеству слоев: Многослойная печатная плата

-

By Material Type: Гибридный / Mixed Material PCB

-

По технологиям: Advanced HDI PCB

-

По приложению: RF Microwave PCB / High-Speed Digital PCB

6. Standard Production Flow

Engineering Design → Material Prep & Shearing → Rogers Material Laser Drilling (Слепые исчезновения) → Desmear & Metallization → Inner Layer Imaging & Etching → Core Lamination (Hybrid Bonding) → Mechanical Drilling → Смола начинка & Curing → Outer Layer Imaging → ENEPIG Surface Finish → Metalized Edge Plating → Solder Mask & Silkscreen → Electrical Test & Заключительная проверка.

7. Основные приложения (Варианты использования)

This product is ideal for high-reliability electronic projects with stringent demands:

-

5G Коммуникационная инфраструктура: RF PCB within AAUs (Active Antenna Units) and remote radio units.

-

Автомобильная электроника: Radar PCBs for ADAS and autonomous vehicles (например, 77GHz radar).

-

Аэрокосмическая промышленность & Оборона: High-Reliability PCBs in radar systems, satellite comms, and EW equipment.

-

High-End Test & Measurement: Core boards for network analyzers and spectrum analyzers.

-

Высокопроизводительные вычисления & Центры обработки данных: Backplanes or motherboards for high-speed servers/switches.

Why Choose UGPCB for Your 6-Layer High-Frequency Hybrid PCB?

In advanced Производство печатных плат, consistency and attention to detail determine success. UGPCB possesses deep expertise across the entire complex process chain—from Rogers material processing и laser drilling к resin filling и ENEPIG plating. We deliver not just boards that meet specifications, but robust PCB solutions that ensure your product’s successful volume production.

Contact us today for dedicated technical support and a competitive quote for your 5G PCB, automotive radar PCB, или high-frequency module PCB project. Let UGPCB be your trusted partner for высокочастотный, high-speed PCB fabrication.