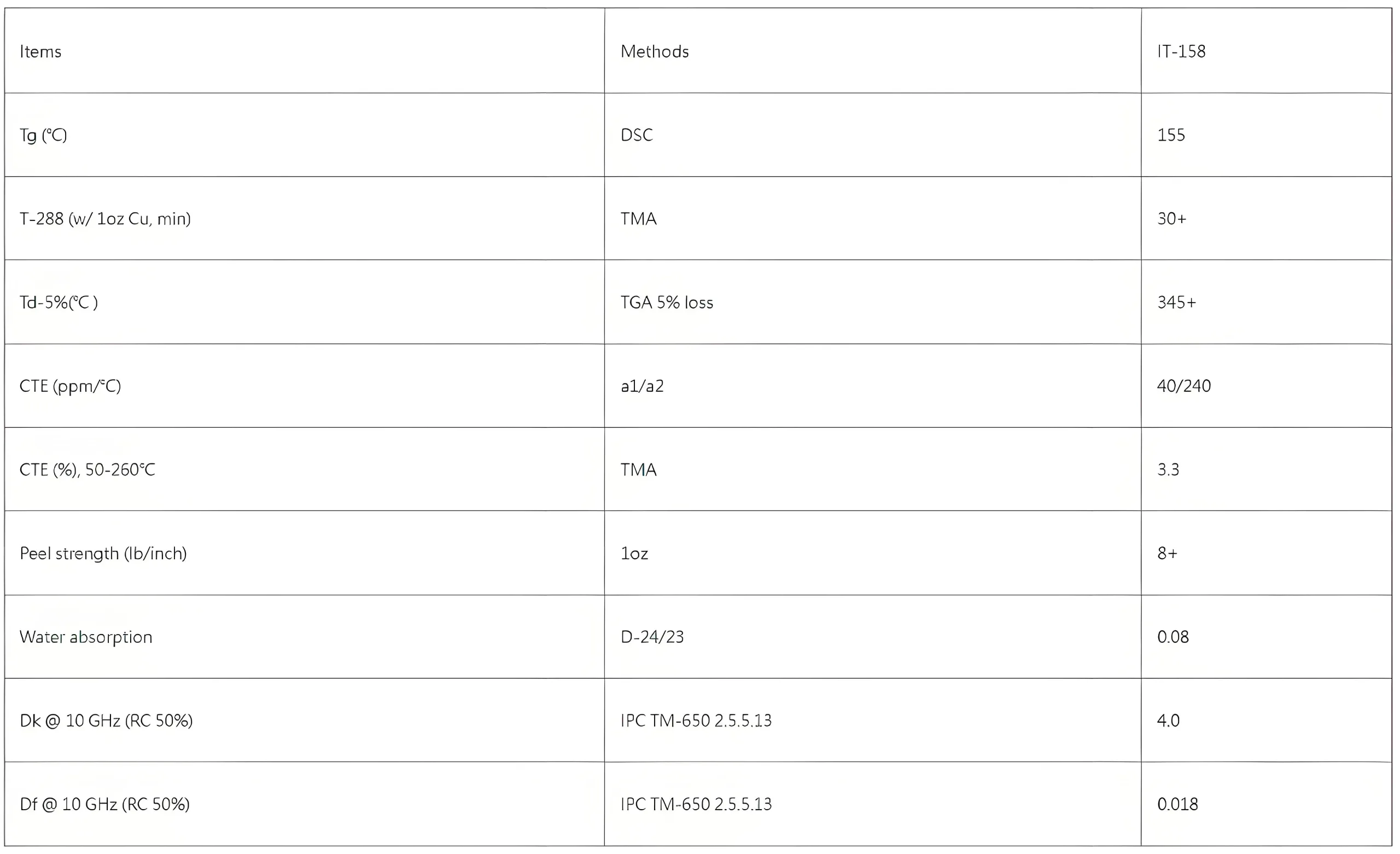

ITEQ IT-158 PCB Board Material

Key Performance Parameters & Technical Advantages

ITEQ IT-158 laminate emerges as a premier choice for high-end PCB manufacturing through exceptional technical specifications:

Thermal Reliability

-

Tg: 155°C (ensures structural stability during lead-free soldering)

-

T-288: >30 seconds at 288°C (superior thermal shock resistance)

-

Td-5%: 345°C (prevents delamination in extreme conditions)

Mechanical Stability

-

Z-axis CTE: 40ppm/°C (3.3% expansion from 50-260°C)

-

Peel Strength: ≥8lb/inch (copper-clad bond integrity)

-

Water Absorption: 0.08% (maintains electrical stability in 85% RH environments)

High-Frequency Signal Transmission Characteristics

Dielectric Performance at 10GHz

-

Dk: 4.0 ±0.05

-

Df: 0.018

*(Ideal for 5G/mmWave applications with 0.15dB/inch insertion loss reduction)*

Typical Application Scenarios

5G Communication Infrastructure

-

Base station antennas

-

Optical transceivers

Automotive Electronics

-

ADAS radar systems (AEC-Q200 compatible)

-

ECU control modules

Industrial Automation

-

Servo drives (10,000hr MTBF at 105°C)

-

Power inverters

Consumer Electronics

-

Smartphone RF modules

-

Laptop motherboard HDI designs

PCB Material Selection Workflow

Phase 1: Requirement Analysis

-

Operating temperature range: Tmax +20°C margin

-

Signal frequency threshold: ≥1GHz critical

-

Environmental rating: IP67 compliance

Phase 2: Comparative Evaluation

| Parameter | ITEQ IT-158 | Competitor A | Competitor B |

|---|---|---|---|

| Tg (°C) | 155 | 140 | 130 |

| Df @10GHz | 0.018 | 0.025 | 0.032 |

| UL Certification | 94V-0 | 94HB | 94V-1 |

Phase 3: Reliability Validation

-

PCT Test: 121°C/100%RH/2atm ×96hr

-

Thermal Stress: 3× solder dips @288°C

-

CAF Resistance: IPC-TM-650 2.6.25 compliant

Design Optimization Strategies

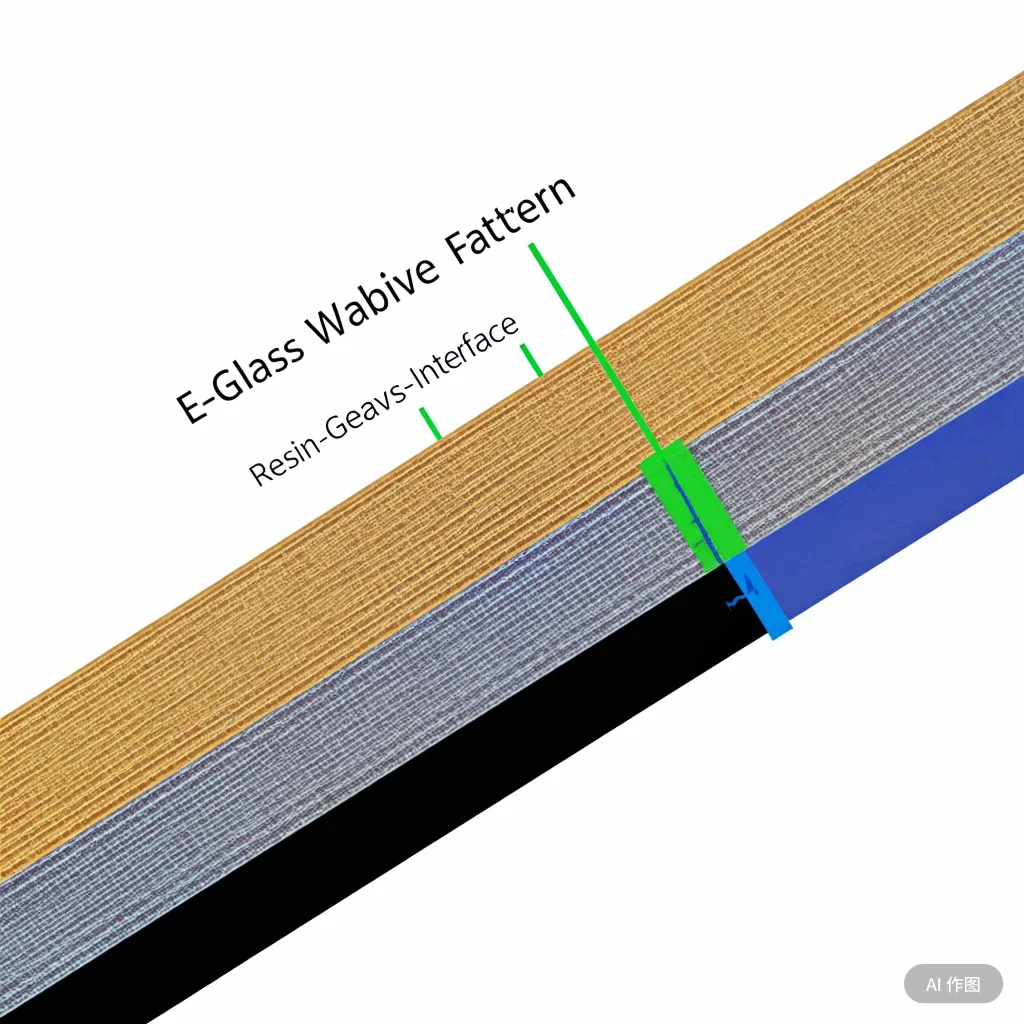

Stackup Configuration

-

Hybrid dielectric construction (≤5% thickness tolerance)

-

Buried vias for thermal management

Impedance Control

-

Microstrip line tolerance: ±10%

-

Differential pair spacing: 3× dielectric height

Manufacturing Process

-

Drilling: Back-drilling with ≤0.15mm stub

-

Surface Finish: ENEPIG preferred (Ni:3-5μm, Au:0.05-0.1μm)

ITEQ IT-158 PCB Substrate Parameter Table

UGPCB LOGO

UGPCB LOGO

Real informative and fantastic anatomical structure of subject matter, now that’s user friendly (:.