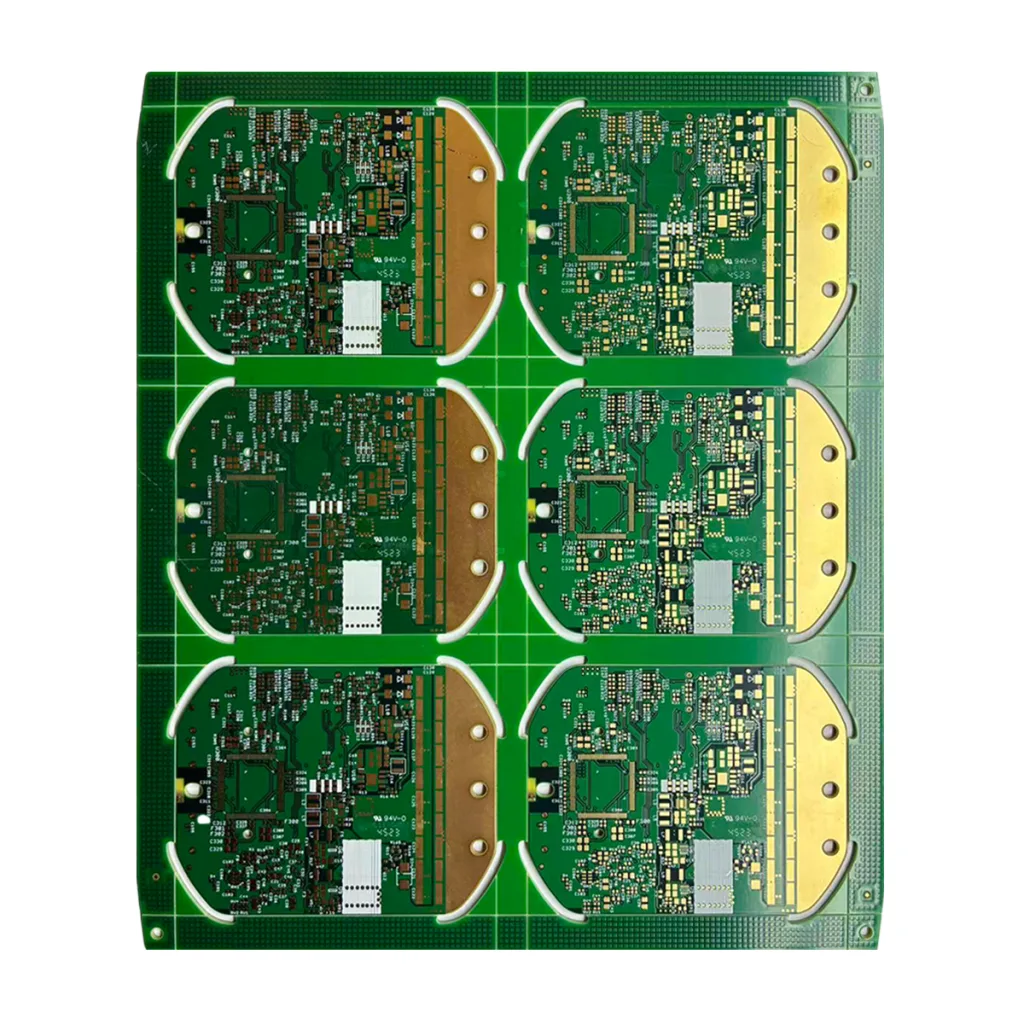

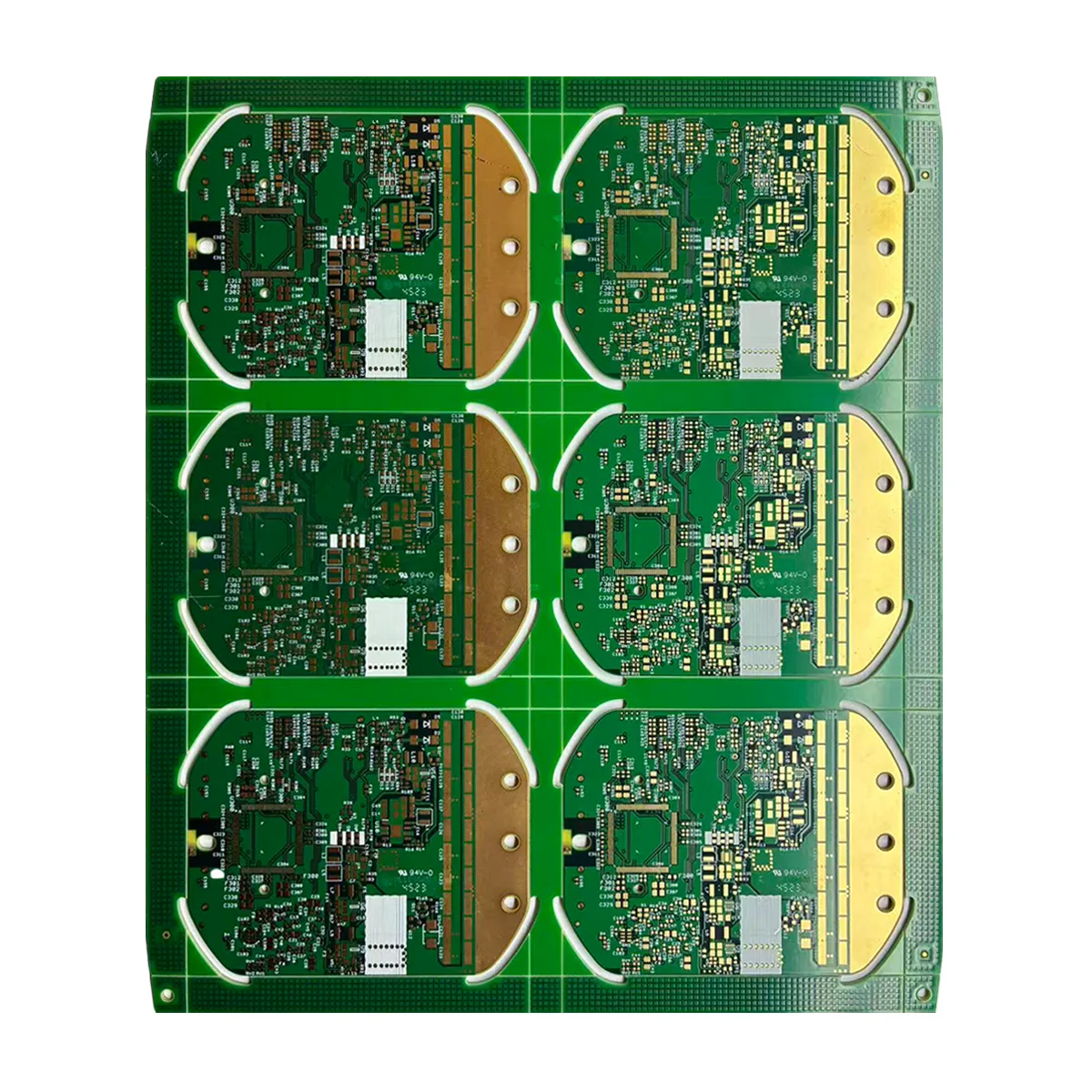

プロフェッショナル製品の概要

The UGPCB 12-Layer Rigid PCB is a high-end 多層回路基板 engineered for complex signal transmission, 高密度相互接続 (HDI), and demanding operating environments. Manufactured with high-performance FR-4 TU872SLK laminate and finished with 2-microinch Immersion Gold (同意する), this board is a cornerstone solution for industrial control systems, 通信インフラ, and advanced computing hardware, offering exceptional electrical performance, long-term reliability, and robust signal integrity.

Product Definition & 分類

This product is classified as a High-Layer Count Rigid Printed Circuit Board. It can be further categorized as:

-

構造によって: 剛性 プリント基板.

-

レイヤーカウントごとに: 12-Layer Multilayer Board (mid-to-high layer count).

-

テクノロジーによって: Standard Multilayer PCB suitable for complex, non-extreme miniaturization designs.

-

By Application Class: Industrial/Telecom-Grade PCB, meeting requirements for high reliability and long-term stability.

設計上の重要な考慮事項

Designing a 12-layer PCB requires meticulous attention to:

-

スタックアップデザイン: A rational stack-up sequence (例えば。, alternating signal-ground-signal layers) is paramount for impedance control, crosstalk reduction, and Electromagnetic Compatibility (EMC). A proper 12-layer stack-up provides excellent power integrity and signal shielding.

-

インピーダンス制御: For high-speed digital signals (例えば。, DDR, PCIE) or RF lines, precise calculation and control of trace characteristic impedance (例えば。, 50Ω シングルエンド, 90Ω/100Ω差動) are essential. We utilize advanced EDA tools and precise process controls to ensure consistency.

-

力 & Ground Plane Management: Solid ground planes and optimized power segmentation ensure low-noise power delivery and clear return paths, which are critical for system stability.

-

熱管理: The 1.6mm board thickness and the thermal properties of FR-4 must align with component power dissipation. High-power areas may require thermal vias or integration with external cooling solutions.

それがどのように機能するか

A PCB is a passive platform that provides mechanical support, electrical interconnection, and signal transmission pathways for electronic components. This 12-layer PCB facilitates a complete working system by connecting chips, 抵抗器, コンデンサ, 等, through a complex network of etched copper traces. The multilayer architecture allows traces to cross on different layers without interference, significantly increasing circuit complexity and integration density. The ENIG surface finish guarantees reliable solder joints and long-term contact stability.

*(Image Suggestion: Detailed cross-sectional diagram of a 12-layer PCB stack-up)*

*代替テキスト: Cross-sectional view of a 12-layer PCB stack-up showing alternating copper layers and dielectric, illustrating complex internal structure for high-density interconnect.*

工事 & 材料

-

Layer Structure: 12 conductive copper layers laminated with insulating prepreg.

-

コア素材: FR-4 TU872SLK. This is a high-performance epoxy glass laminate offering advantages over standard FR-4:

-

Higher Thermal Stability (高ガラス転移温度, typically ≥170°C), providing better resistance to thermal expansion.

-

Superior Electrical Properties, with stable Dielectric Constant (DK) および散逸係数 (Df) under high-temperature and high-frequency conditions.

-

Excellent CAF (Conductive Anodic Filament) Resistance, ideal for high-voltage, high-humidity environments, ensuring superior reliability.

-

-

仕上がり厚さ: 1.60mm (nominal), with tight tolerance control (通常±10%).

-

表面仕上げ: エレクトロレスニッケルイマージョンゴールド (同意する). ニッケルの厚さ: 3-5μm; 金の厚さ: 2 microinches (約. 0.05μm). The gold layer protects the nickel from oxidation, providing a flat, はんだ付け可能な表面, while the nickel acts as a diffusion barrier between copper and gold.

主な特長 & パフォーマンス

-

高い信頼性: TU872SLK high-Tg material and ENIG finish ensure resistance to high temperatures, 腐食, and suitability for long-term operation in harsh environments.

-

優れた信号の完全性: Rigorous stack-up design and impedance control guarantee high-speed signal quality and lower bit error rates.

-

Strong Load-Bearing & Thermal Capacity: The 1.6mm thickness offers robust mechanical strength and substantial thermal load management.

-

Precision Solder Platform: The flat 2μ” ENIG surface is ideal for fine-pitch コンポーネント (例えば。, BGAS), resulting in strong, reliable solder joints with low defect rates.

-

高密度相互接続 (HDI): Twelve routing layers support complex, dense circuit designs, enabling reduced product footprint.

Manufacturing Process Flow

Inner Layer Imaging → AOI Inspection → Lamination & Pressing → Drilling → Electroless Copper Deposition → Outer Layer Imaging → Pattern Plating → Etching → Solder Mask Application → ENIG Surface Finish → Routing & Profiling → Electrical Testing → Final Quality Control (FQC)

アプリケーション & ユースケース

This PCB is widely used in stability and performance-critical fields:

-

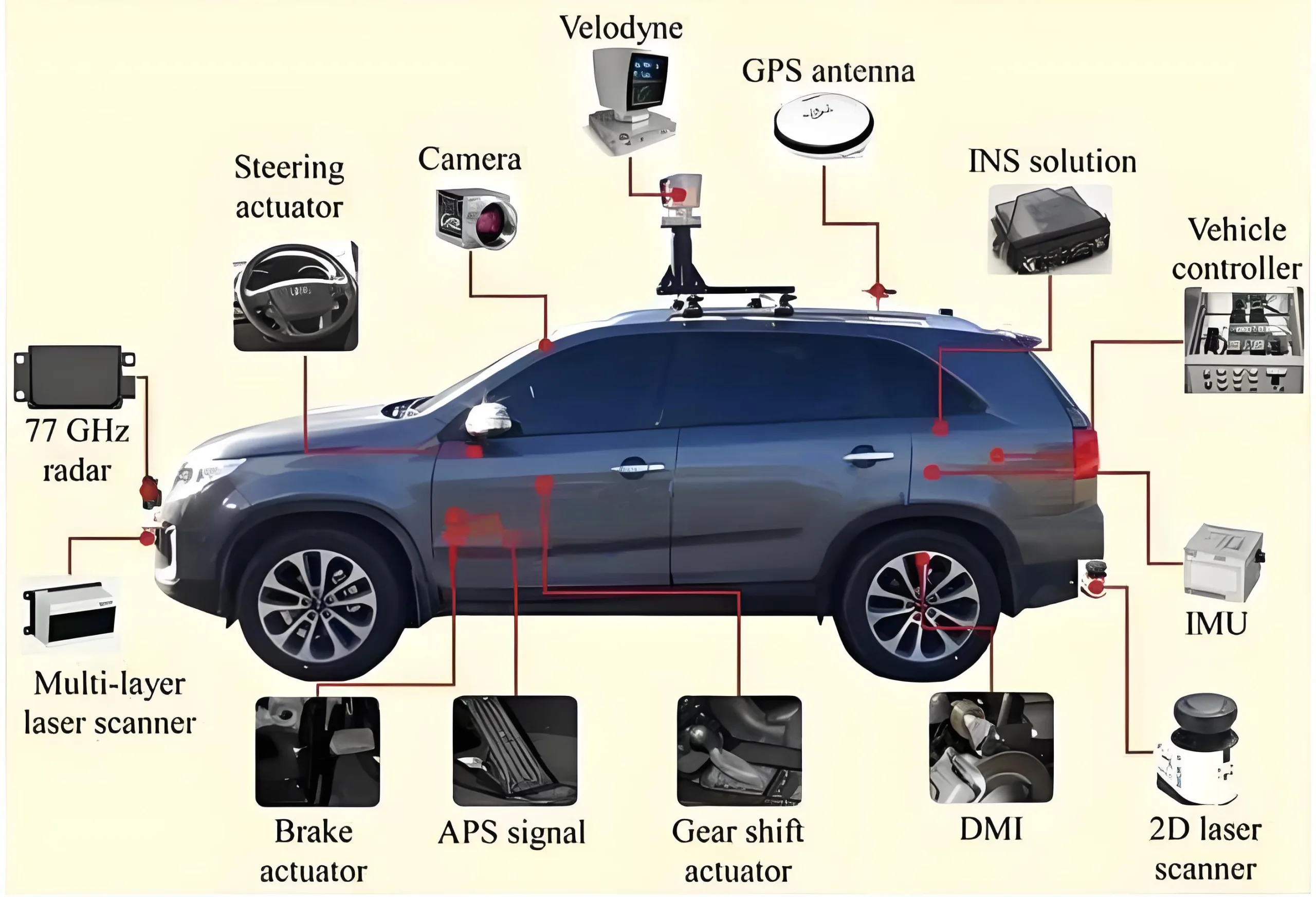

産業用自動化: PLC controllers, servo drives, industrial robot control boards.

-

Telecommunications Equipment: ルーター, スイッチ, base station cards, optical modules.

-

医療エレクトロニクス: Control units for advanced medical imaging systems, patient monitors.

-

テスト & 測定器: High-precision oscilloscopes, スペクトラムアナライザ, signal generators.

-

力 & Energy: Inverter control boards, バッテリー管理システム (BMS) ボード, smart meters.

-

カーエレクトロニクス: High-end infotainment systems, 高度なドライバー支援システム (アダス) domain controllers.

UGPCBのロゴ

UGPCBのロゴ