テフロン高周波マイクロ波PCB基板

テフロンPCBが使用するPCB材料, F4BMはガラス織布をラミネートしたものです, 接着剤フィルム, テフロン樹脂と四フッ化エチレンフィルム, 科学的公式と厳密な技術プロセスに従って. この製品は、電気的性能において F4B シリーズに比べていくつかの利点があります。 (より広い範囲の誘電率, 誘電正接が低い, 抵抗の増加, より安定したパフォーマンス).

誘電率: 2.20 2.55 2.65 3.0

寸法(mm): 300*250 380*350 440*550 500*500 460*610 600*500 840*840 840*1200 1500*1000

特別な次元の場合,カスタマイズされたラミネートが利用可能です.

ラミネートの厚さ(mm): 0.25 0.5 0.8 1.0 1.5 2.0 3.0 4.0 5.0 6.0 8.0 10.0 12.0

テフロン高周波マイクロ波PCB基板

テフロン基板は耐候性などの優れた特性を備えているため、一般的なFR4基板の代替として広く使用されています。, 高い断熱, 高い潤滑, 非粘着性、非毒性. しかし, 通常のFR4ボードとの比較, テフロン PCB ボードは固体材料の中で最も表面張力が小さいです, いかなる物質にも付着しません, 機械的特性が非常に小さい. その摩擦係数はたったの 1 / 5 ポリエチレンのもの, これはパーフルオロカーボン表面の重要な特徴です. 加えて, フッ素炭素鎖の低い分子間力による, テフロンはベタつかない, そのため、テフロン基板の製造工程において基板表面に付着しにくい.

私たちの利点

1. 迅速な対応,24 オンラインサービス時間

2. MOQ要件なし

3. 多様な機能

4. 迅速な対応が可能

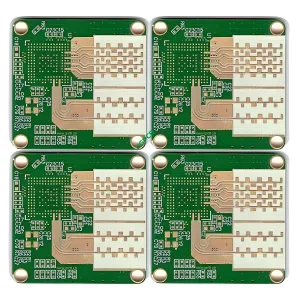

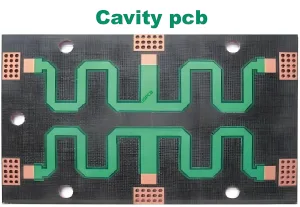

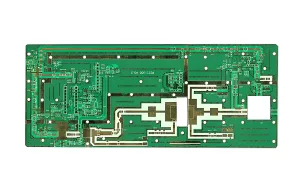

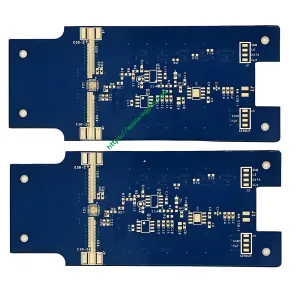

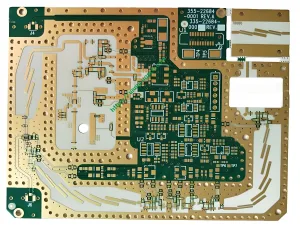

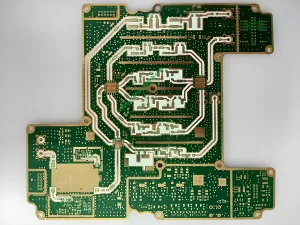

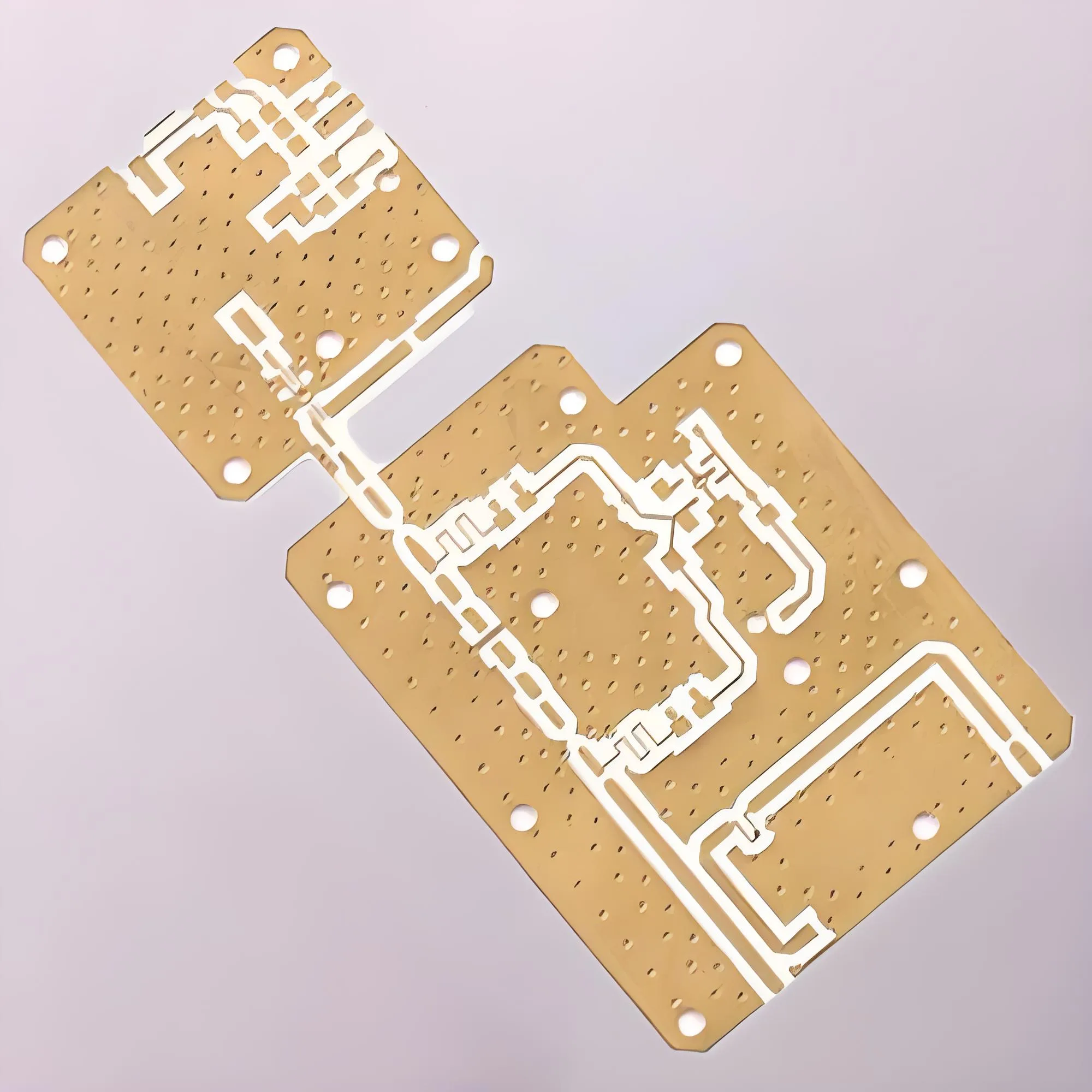

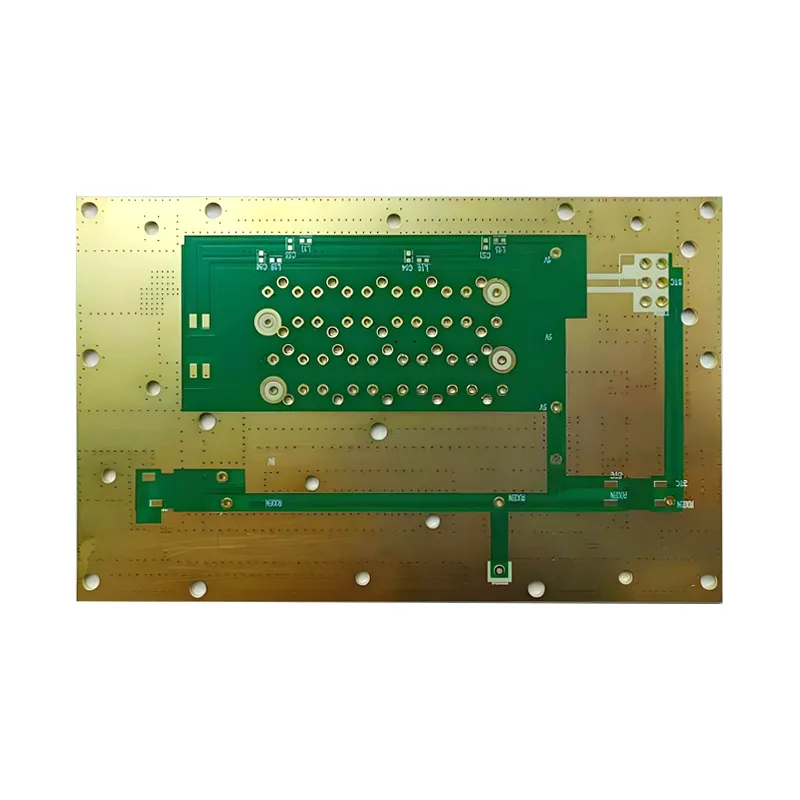

リアルプロジェクト表示:

誘電体DKの幅が広い, DF角度の接線値は低くなります, 抵抗値が増加します, パフォーマンスはより安定しています.

RF/マイクロ波テフロン PCB アプリケーション

高周波対応テフロン PCB(RF PCB) PCB業界ではますます使用されている技術です.

–上記の作品を備えた高頻度のRF PCB 100 MHz.

–上記の作品を備えたマイクロ波PCB 2 GHz無線周波数.

テフロン PCB はリモコンなどのさまざまな用途に使用されています(ワイヤレスコントロール)安全,スマートフォン,センサーなど.

新しいテクノロジーは、これらのRFアプリケーションをますます多く使用します.

これは、高品質の基準に従って製造を要求し、アプリケーションに応じて適切なRF材料を選択する.

さまざまな材料の特性を知っていることが重要です. 適切な材料を選択することは、おそらくテフロン PCB の製造プロセスにおいて最も重要な決定です。.

UGPCBのロゴ

UGPCBのロゴ