UGPCB排水処理システム: PCB業界におけるグリーンマニュファクチャリングの新たなベンチマークを設定

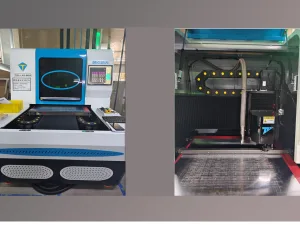

設備概要とコア技術分析

UGPCB モジュール式のインテリジェント廃水処理システムを採用, 重金属および有機汚染の特性が高い地域に対処するために特別に設計されています。 プリント基板 業界. このシステムは 3 つのコア技術モジュールを統合しています: 化学沈殿, 膜分離, IoT監視. それは次のことを実現します:

-

重金属除去率≧ 99.8% (GB21900-2020表に準拠 3 標準)

-

CODcr処理効率 92% (を超える “電子産業の汚染物質排出基準”)

-

100% 銅回収率 (電着技術による資源循環を実現)

このシステムはIoTベースのインテリジェント制御システムを利用して監視します。 20 リアルタイムのパラメータ, pHレベルを含む, 重金属濃度, と流量. データはクラウドプラットフォームにアップロードされます, 有効化:

-

遠隔故障診断 (応答時間 ≤ 15 分)

-

化学薬品投与のインテリジェントな最適化 (化学薬品の使用量を大幅に削減 30%)

-

動的エネルギー消費調整 (消費電力 ≤ 3.5 処理水1トン当たりのkWh)

環境技術 UGPCBのメリット

クローズドループ資源循環システム

-

排水再利用率 85%: 逆浸透の組み合わせによって実現 (ロ) および限外濾過 (フロリダ州) プロセス, GB/Tを満たす処理水質 19923-2005 工業用水再利用基準.

-

金属資源の回収: 年間回収量 1,200 トンの銅, 錫, および他の金属, ~の経済的利益を生み出す 24 百万元 (に基づく 2025 市場価格).

IoT対応のインテリジェントな運用と保守

-

機器の健全性予測: 振動センサーと AI アルゴリズムを利用して、潜在的な障害を早期に警告します。 72 数時間前に.

-

炭素排出管理: 統合された二酸化炭素排出量計算モジュールは、処理プロセス中にリアルタイムの二酸化炭素排出データを表示します.

認定と標準的なリーダーシップ

-

ISO 14001 環境管理システム認定

-

UL認定 (ECOLOGO®環境ラベル認証)

-

ROHS準拠 (EU の有害物質制限指令に適合)

PCBA生産における環境慣行

で プリント基板 (印刷回路基板アセンブリ) 段階, UGPCBは鉛フリー生産体制を確立:

-

鉛フリーはんだの使用: 鉛を含むSn-Ag-Cu合金を採用 < 0.1%

-

排ガス処理装置: 活性炭吸着技術と触媒燃焼技術を組み合わせて、VOC 排出量を 10mg/m3 未満に維持します。

-

電気集塵機: 粒子状物質捕集効率の達成 ≥ 99.9%

業界への影響と社会的責任

業界標準のアップグレードを推進

-

草案作成への参加 “中国電子回路産業協会の環境技術基準”

-

PCB排水処理のエネルギー消費基準策定への関与 (≤ 4.0 水1トンあたりkWh)

グリーンサプライチェーンの開発

PCB廃棄物トレーサビリティプラットフォームの導入, 原材料からリサイクルまでの全プロセスの追跡を可能にする.

環境効果データ

-

年間排出量削減: 代金引換 180 トン, アンモニア態窒素 25 トン, 重金属 3.2 トン

-

節水効果: 年間削減量 400,000 淡水消費量の立方メートル

将来のテクノロジーの展望

UGPCB は現在、生物電気化学結合処理技術を開発中です。, 以下のような結果が予想されます:

-

40% 治療費の削減 (~による目標達成 2026)

-

マイクロエレクトロニクスグレードの純水の再利用を実現 (抵抗率≧ 18 MΩ・cm)

UGPCBのロゴ

UGPCBのロゴ