In the field of electronic engineering, the layer count of a 인쇄 회로 기판 (PCB) is often a direct indicator of a product’s complexity and technological sophistication. While most engineers routinely work with 2, 4, or 6-layer boards—with consumer electronics even employing cost-optimized solutions like “pseudo-8-layer” boards (6 functional electrical layers plus 2 insulation layers for thickness)—the landscape shifts dramatically in high-end servers, high-performance computing motherboards, and cutting-edge communication equipment. 여기, PCBs with 16, 32, or even 64 layers are common. This raises a critical question: what are the underlying design principles and manufacturing technologies that enable these high-layer count PCBs? This article provides an in-depth analysis of the technical aspects, core challenges, and advanced manufacturing solutions for high-layer count PCBs.

Why High-Layer Count PCBs? More Than Just a Routing Game

Increasing PCB layer count is not about pursuing impressive numbers. The fundamental driver is the exponential growth in performance demands of modern electronic devices. When chip pin density continues to rise (예를 들어, BGA packages with over 2500 solder balls), signal speeds enter the GHz regime (예를 들어, PCIE 5.0 ~에 32 GT/초), and systems must simultaneously handle high-speed digital, RF analog, and high-power signals, 전통적인 4 or 6-layer boards become inadequate.

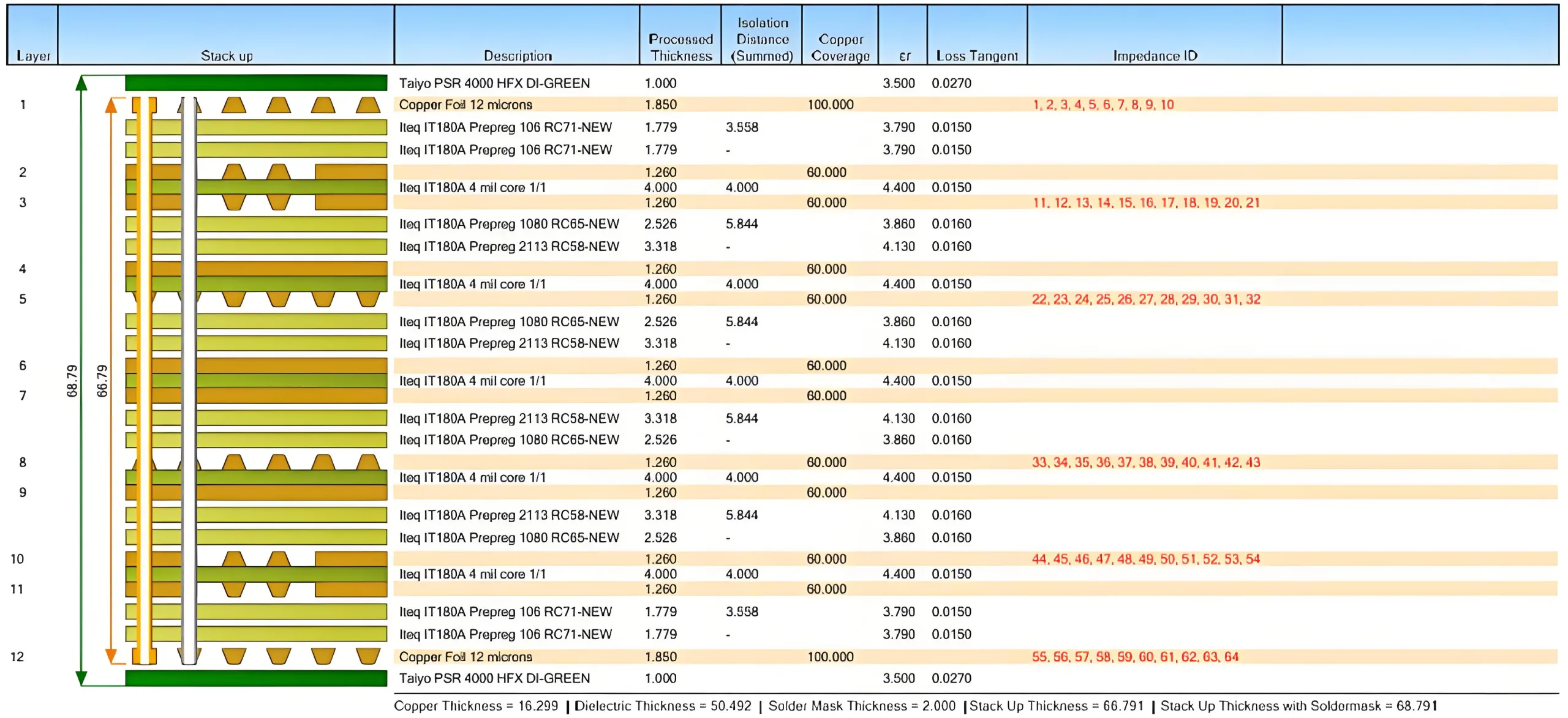

The core value of high-layer count PCBs lies in providing ample routing resources and complete reference planes. A typical 12-layer board stack-up might be: 신호 1 / 지면 / 신호 2 / 힘 1 / 신호 3 / 지면 / 신호 4 / 힘 2 / 신호 5 / 지면 / 신호 6. This symmetrical “ground-signal-power-signal-ground” stack-up (following guidelines like IPC-2141A) effectively controls impedance and provides a low-noise return path for high-speed signals. Statistics show that in equipment like data center switches, designs using PCBs with 20+ layers can reduce crosstalk in critical network signals by over 60% (data referenced from IPC TR-579 report).

Design Challenges for High-Layer Count PCBs: Beyond “Drawing Traces”

Signal Integrity and Impedance Control

In high-speed design, PCB traces are no longer simple electrical connections but must be precisely controlled transmission lines. Deviations in characteristic impedance (예를 들어, 50Ω 단일 종단, 90Ω/100Ω differential) directly cause signal reflection, overshoot, and data eye diagram closure. Impedance primarily depends on trace width (w), 유전체 두께 (시간), 유전 상수 (εr), 그리고 구리 두께. Industry-standard tools like Polar Si9000 model this using simplified formulas (마이크로스트립 라인용):

Z0 ≈ (87 / √(εr + 1.41)) * ln(5.98 * H / (0.8 * W + T))

where T is trace thickness. For common FR-4 material (εr ≈ 4.2 @ 1GHz), to achieve 50Ω impedance with a dielectric thickness H=5 mil, the trace width W needs to be controlled at approximately 8.5 밀. 하지만, non-uniformity in the laminated structure of high-layer count boards, the glass weave effect, and production etching tolerances (typically ±10%) all introduce impedance variations. The IPC-6012D standard allows a ±10% deviation of the measured value from the nominal impedance for controlled impedance boards, but high-end applications now demand tolerances as tight as ±7%.

Power Integrity and PCB Thermal Management

As layer count increases, the complexity of Power Distribution Network (PDN) design grows exponentially. Core voltages can be as low as 0.8V with transient currents reaching hundreds of amps. In this scenario, the target impedance of the power planes must be extremely low (예를 들어, <1 MΩ) to suppress voltage ripple. This requires careful planning of decoupling capacitor placement, optimization of inter-plane capacitance between power and ground planes (calculated by C = ε0 * εr * A / d, where A is the overlapping area and d is the dielectric thickness), and may necessitate dedicated power layers. 뿐만 아니라, increased power density due to high-density routing (엄청난 100 W/cm² in some ASIC areas) requires enhanced cooling through thermal via arrays, embedded copper coins, or metal substrates, adding further complexity to stack-up design and processing.

The Alchemy of PCB Manufacturing: The Precision Process Chain for High-Layer Count Boards

Transforming design into physical reality presents another significant challenge for high-layer count PCBs. The core process can be summarized as a precise cycle of “lamination – alignment – drilling – plating.”

Layer-to-Layer Alignment: The Art of Micron-Level Registration

All layers of a multilayer board (inner layer cores and prepreg) must be laminated into a single unit under high temperature and pressure. Layer misregistration can cause drills to cut off traces, create shorts, or cause impedance discontinuities. For a 16-layer board, if the mean alignment error per layer is 25 μm (the graphic registration tolerance allowed by IPC-A-600G Class 3), the worst-case cumulative error could exceed 100 μm—enough to compromise a 0.2 mm BGA pad.

Leading manufacturers like UGPCB tackle this challenge using 레이저 직접 이미징 (LDI) 그리고 high-precision optical alignment systems. Alignment pins 그리고 global fiducial scales etched on each core layer, combined with CCD vision capture and servo adjustment, can control layer-to-layer registration within 15 μm (data based on leading industry vendor process whitepapers). 추가적으로, material rheology analysis to predict resin flow and glass fiber orientation of prepreg during lamination allows for pre-compensation of dimensional deformation, ensuring uniform dielectric thickness after pressing.

https://example.com/pcb-lamination-alignment.png

Image Alt Text: Detailed explanation of multilayer PCB lamination and alignment process, showing laser targets, optical alignment, and lamination flow, ensuring high-precision layer-to-layer registration.

Via Interconnection: From Through-Holes to Any-Layer HDI

Traditional through-holes penetrate the entire board thickness, occupying significant routing space in high-layer count PCBs and causing long signal return path problems. 그러므로, 고밀도 상호 연결 (HDI) 기술 enables more flexible layer transitions using 블라인드 비아 (from surface to inner layer), 묻힌 vias (inner layer to inner layer), 그리고 마이크로 비아 (diameter ≤ 0.15 mm).

예를 들어, a “1+N+1” HDI structure (where surface layers use microvias and the middle is an N-layer traditional core) can increase routing density by over 40% without increasing total layer count (referencing IPC-2226 HDI design standard). 하지만, this introduces process complexities like sequential lamination drilling, via filling and plating, 그리고 multiple lamination cycles. Manufacturers must equip laser drilling machines (for microvias), vertical vacuum plugging machines (to ensure void-free filling), 그리고 plasma cleaning equipment (to remove drill smear), and perform rigorous 비행 프로브 테스트 그리고 four-wire Kelvin testing to verify the reliability of every interconnection point.

미래의 트렌드: Material Innovation and Simulation-Driven Design-Manufacturing Integration

The evolution of high-layer count PCBs continues. As signal rates advance towards 56Gbps and beyond using PAM4 modulation, low-loss materials (like Panasonic MEGTRON 6, 로저스 RO4000 시리즈) with εr as low as 3.2 소산 인자 (Df) 아래에 0.002 are being adopted. 동시에, embedded components (like buried resistors and capacitors) 그리고 semiconductor package integration (예를 들어, Intel’s EMIB, TSMC’s SoIC) are blurring the lines between PCBs and ICs.

For designers and procurement specialists, selecting a qualified high-layer count PCB 공급업체 is paramount. Beyond focusing on their maximum layer capability (예를 들어, stable mass production of 32 레이어), 임피던스 제어 capability (whether they provide impedance test reports), 그리고 HDI process level (minimum hole size/trace width), it is crucial to evaluate their design support services (such as SI/PI simulation and stack-up optimization advice) 그리고 quality control system (adherence to IPC Class 3 standards and availability of comprehensive inspection equipment like AOI, AVI, 3D X-ray).

Seeking a high-reliability, 고성능 다층 PCB 해결책? Contacting a professional supplier with full-chain capabilities from design simulation to precision manufacturing to obtain a custom stack-up design proposal 그리고 instant quote for your project is the first critical step toward success. In the era of the Internet of Everything and computational explosion, high-layer count PCBs are no longer just carriers; they are the foundational cornerstone defining the performance limits of electronic systems.