Introduzione

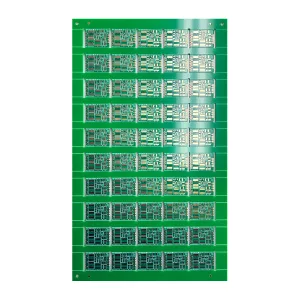

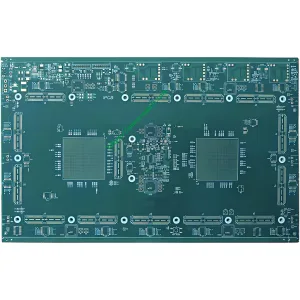

UGPCB‘s 2-Layer Rigid PCB is a fundamental, Alta affidabilità circuito solution engineered for demanding applications. Built on a robust Substrato FR-4 TG150 with a standard 1.60mm thickness, it delivers an optimal balance of performance, durability, ed efficienza in termini di costi. The board features a reliable lead-free Hot Air Solder Leveling (Sanguinare) finitura superficiale, a protective black solder mask, and clear white silkscreen legends for identification.

Panoramica del prodotto & Classificazione

This double-sided PCB serves as a core interconnect platform for a wide range of electronics. It is scientifically classified as a PCB rigido (by construction), UN 2-Layer or Double-Sided Board (by layer count), and is rated for Industrial Grade (Classe IPC 2) applications based on its FR-4 TG150 material specification, making it suitable for extended lifecycle products.

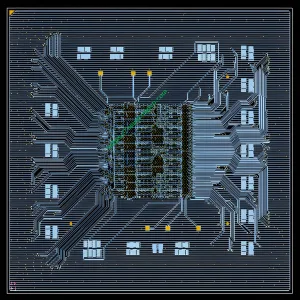

Progetto & Principio operativo

Successful implementation requires attention to electrical and thermal design rules. Adequate trace width for current capacity (per esempio., 1A per 10mil trace width for 1oz copper) and strategic placement of thermal reliefs are critical. The PCB functions as a miniature city: IL FR-4 substrate is the foundation, copper traces are the roads carrying signals and power, plated through-holes are interlayer connectors, IL maschera di saldatura is a protective coating, and the silkscreen provides navigation.

Costruzione, Materiali & Prestazione

The symmetrical stack-up ensures mechanical stability. Key materials define its capabilities:

-

Nucleo: FR-4 TG150 Laminate (Tg ≥ 150°C) provides high thermal endurance and stability.

-

Rame: Standard 1oz (35µm) electrodeposited copper foil.

-

Finiture: Black LPI solder mask and white epoxy silkscreen.

-

Finitura superficiale: Lead-Free HASL for excellent solderability.

This combination yields high heat resistance, superior electrical insulation, strong mechanical rigidity (from the 1.60mm thickness), and excellent solder joint reliability.

Processo di produzione & Controllo di qualità

Our production follows Standard IPC, encompassing CAM engineering, precision drilling, elettroplazione, LPI solder mask application, legend printing, lead-free HASL surface finishing, and electrical testing. Every board undergoes 100% electrical testing and Ispezione ottica automatizzata (AOI) to meet stringent quality criteria.

Applicazioni

This versatile PCB is ideal for:

-

Industrial Control Systems: PLCS, azionamenti a motore, sensor interfaces.

-

Elettronica di potenza: Switch-mode power supplies (SMPS), UPS boards, LED drivers.

-

Automobilistico & Elettronica di consumo: Auxiliary control modules, amplificatori audio, appliance controllers.

Key Specifications Table

| Parametro | Specifica |

|---|---|

| Strati | 2 |

| Spessore della scheda | 1.60 mm (Standard) |

| Materiale di base | FR-4, Tg ≥ 150°C |

| Copper Weight | 1 oz (35 µm) Standard |

| Maschera di saldatura | Nero, LPI |

| Silkscreen | Bianco |

| Finitura superficiale | HASL senza piombo |

| Min. Traccia/Spaziatura | ≥ 0.15 mm (6 mil) |

| Standard Compliance | IPC-A-600, Classe IPC 2 |

LOGO UGPCB

LOGO UGPCB