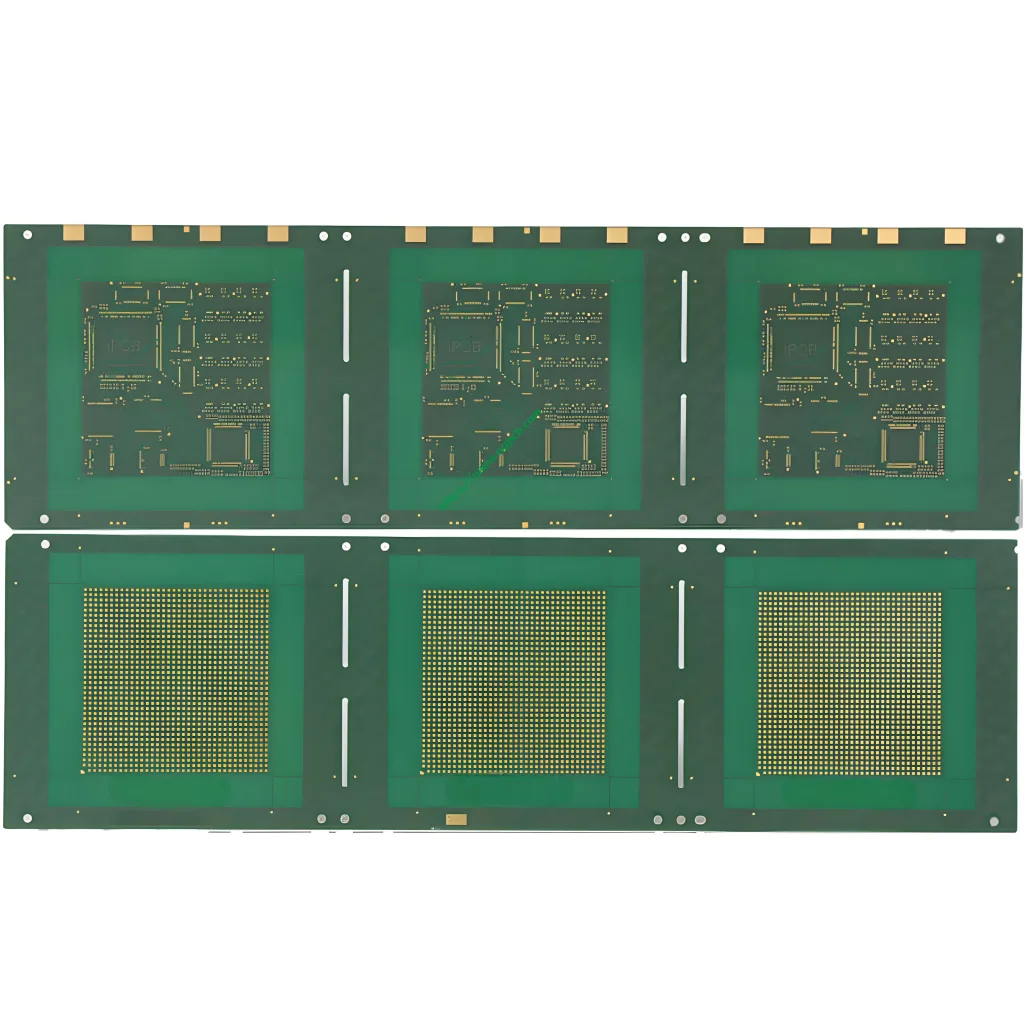

Panoramica del prodotto: What is an HDI IC Substrate Board?

An HDI IC Substrate Board is a critical, high-end circuito stampato engineered specifically for semiconductor package interconnection. It acts as the essential interface, providing electrical connectivity, distribuzione di potenza, and mechanical support between a finely-pitched silicon die and a standard motherboard PCB. UGPCB delivers high-reliability, advanced HDI IC Substrate manufacturing, meeting the stringent demands of applications from consumer electronics to high-performance computing.

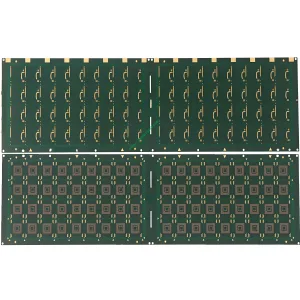

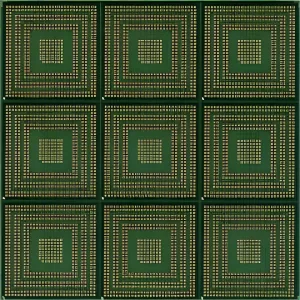

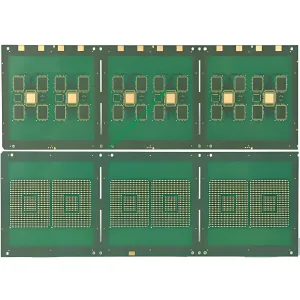

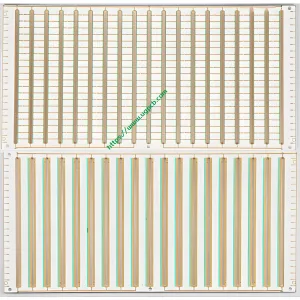

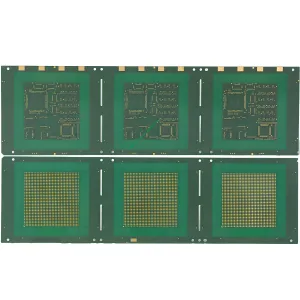

This board, built with SI10U material in a 6-strato (2+2+2) construction and a slim profile of 0.6mm, exemplifies state-of-the-art ISU tecnologia. With a 35x35mm unit size, it features a 0.1mm minimum laser via diameter, 30μm minimum trace width / 70μm minimum spacing, E Enepico (Elettroless Nickel Electroless Palladium Immersion Gold) finitura superficiale, making it an ideal solution for packaging high-speed, alta frequenza, and highly integrated chips.

In-Depth Analysis: Progetto, Funzione, and Applications

Core Definition & Principio di lavoro

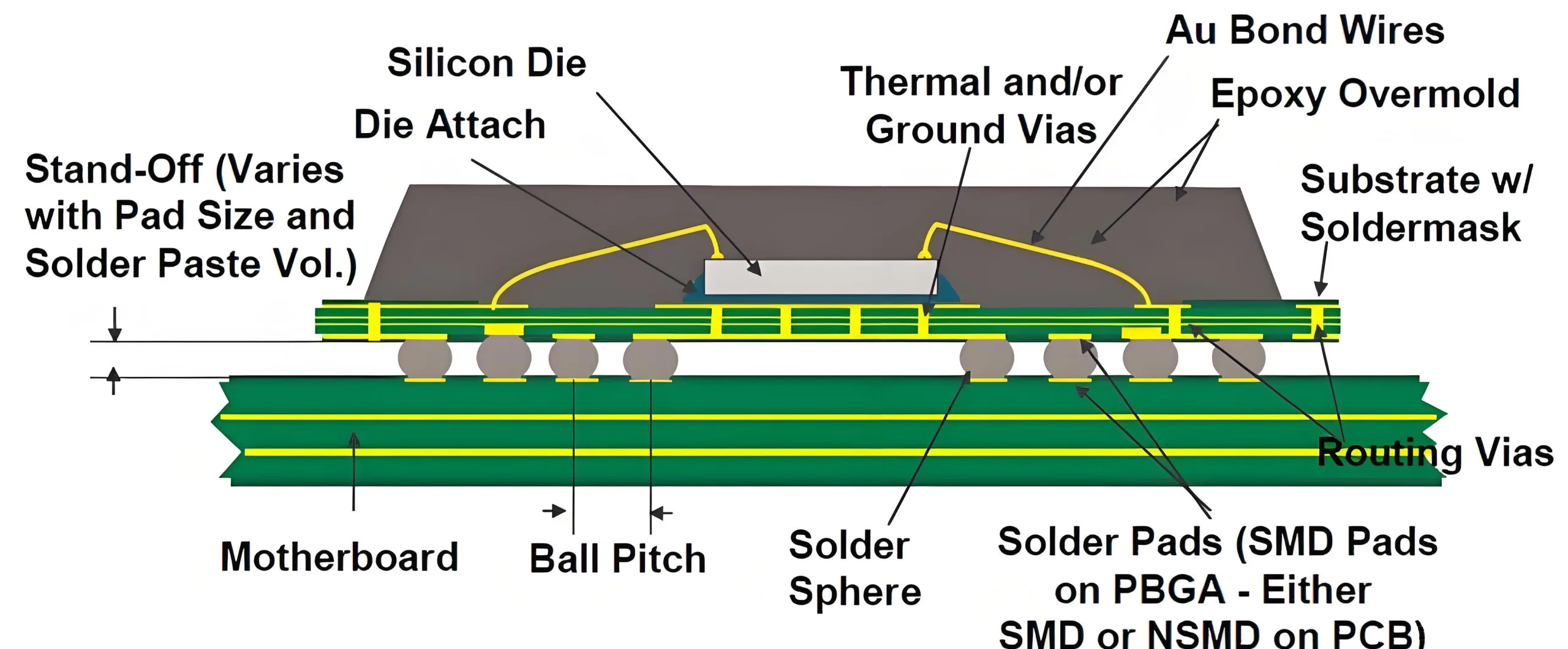

The HDI IC Substrate is designed to “fan-out” the dense array of micro-bumps from a semiconductor die, redistributing the connections to a larger pitch compatible with standard Assemblaggio PCB processes like BGA (Array a sfera) mounting.

The working principle follows this chain: Die → Microbumps → HDI IC Substrate (for signal redistribution & interconnessione) → Solder Balls (BGA/CSP) → Mainboard PCB. It is pivotal for signal integrity, power delivery, e gestione termica.

Considerazioni chiave sulla progettazione

-

Stack-up & Controllo dell'impedenza: The 6-layer (2+2+2) build-up is a classic design for high routing density. Precise impedance calculation (typically 50Ω single-ended or 100Ω differential) is crucial for signal integrity.

-

Micro-via Reliability: 0.1mm (100μm) laser-drilled micro-vias are key for interconnect density. Via shape, placcatura di rame, and fill process must be optimized for thermal cycle reliability.

-

Fine-Line Fabrication: 30μm trace width and 70μm spacing are core metrics of process capability, directly impacting I/O density and electrical performance.

-

Thermal & Mechanical Management: The selection of SI10U material considers its Coefficient of Thermal Expansion (Cte) matching with silicon to minimize thermal stress and enhance product longevity.

Primary Materials & Caratteristiche delle prestazioni

-

Core Material: Si10u. A high-performance laminate offering low dielectric constant (Non so), low dissipation factor (Df), high glass transition temperature (Tg), ed eccellente stabilità dimensionale, ideal for high-speed, high-frequency applications.

-

Maschera di saldatura: PSR-4000 AUS308. A high-resolution, high-reliability Liquid Photoimageable Solder Mask (LPSM) that provides precise coverage, excellent insulation, e resistenza chimica.

-

Finitura superficiale: Enepico. This finish deposits sequential layers of Nickel, Palladium, and Gold. Nickel acts as a diffusion barrier, Palladium prevents nickel corrosion, and the thin gold layer offers superior solderability and wire-bonding capability, perfect for fine-pitch pads.

-

Performance Summary: High density, ad alta velocità, alta affidabilità, Ottima gestione termica, and superior signal integrity.

Classificazione & Scenari di applicazione

HDI IC Substrates are categorized by technology and application:

-

By Technology: With core (per esempio., this 6L build-up) or coreless types.

-

Per applicazione:

-

Advanced Processors: processore, GPU, AI accelerator chips requiring maximum routing density and signal speed.

-

Mobile & Rf: Smartphone Application Processors (AP) e moduli RF, where miniaturization and thin profiles (0.6mm) are critical.

-

Memoria: Interface substrates for High Bandwidth Memory (HBM).

-

Networking & Automobilistico: High-speed switch chips and ADAS domain controllers.

-

UGPCB’s Manufacturing Process & Garanzia di qualità

UGPCB’s production integrates leading-edge processes compliant with IPC standards:

-

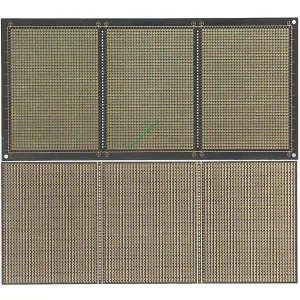

Perforazione laser: UV laser systems create precise 0.1mm micro-vias.

-

Placcatura & Via Fill: Advanced pulse plating ensures complete via filling for reliable interconnects.

-

Advanced Imaging: High-end exposure systems and high-resolution dry film achieve 30/70μm line definition.

-

Laminazione: Precise alignment and pressing of multiple core layers and prepreg (PP).

-

Finitura superficiale: Application of the Enepico coating for optimal solderability.

-

Test completi: Utilizes AOI (Ispezione ottica automatizzata), test delle sonde volanti, and impedance testing to guarantee compliance.

Nostro one-stop PCB servizio capability extends from Substrato del circuito integrato produzione to subsequent Assemblaggio SMT E test, offering a complete packaging solution.

Why Choose UGPCB for Your HDI IC Substrate?

-

Advanced Process Capability: Proven expertise in 30/70μm trace/space E 0.1mm micro-via tecnologia.

-

Materials Expertise: In-depth knowledge of advanced materials like Si10u to recommend optimal solutions.

-

Uncompromising Quality: Stringent, automotive-grade quality control throughout the entire process.

-

One-Stop Solution: We are more than a PCB fabricator; we are your PCBA partner, offering design support, produzione, e assemblaggio.

-

Expert Support: Dedicated engineering team provides DFM (Progettazione per la produzione) analysis and technical consultation.

Ottieni ora la tua soluzione personalizzata

Whether you are developing the next HPC platform, 5Infrastruttura G, O ADAS system, UGPCB’s professional HDI IC Substrate manufacturing E PCBA assembly services are your foundation for success.

Contact us today for a free technical consultation and quote! Let our experts help you enhance product performance through optimized IC substrate design and reliable Fabbricazione di PCB processi.

LOGO UGPCB

LOGO UGPCB