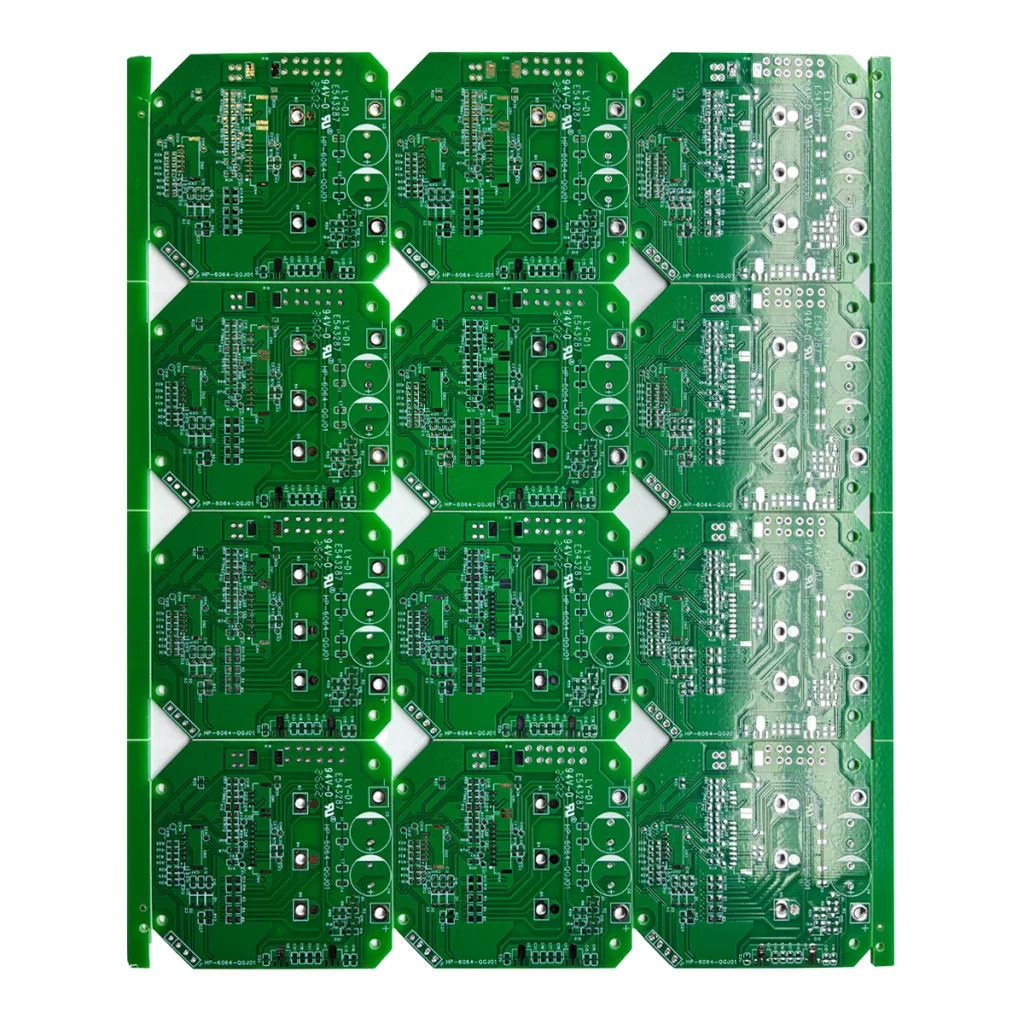

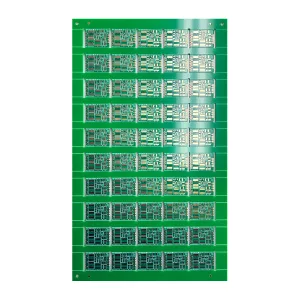

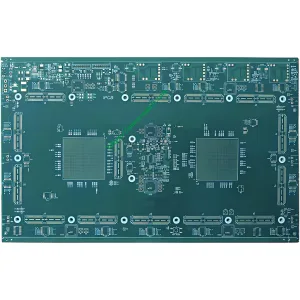

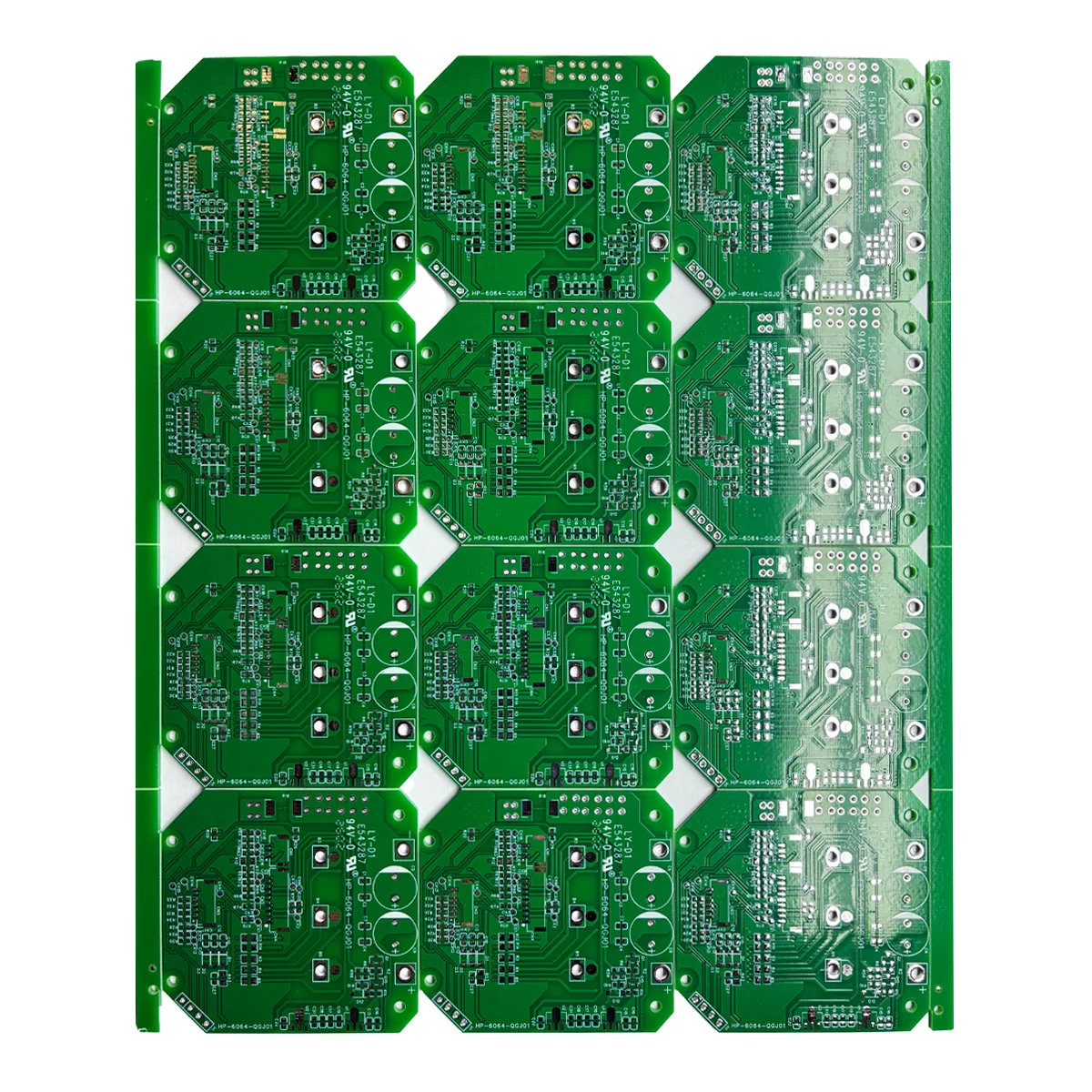

High-Performance FR-4 Double-Sided PCB 製品の概要 & 意味

これ 2-Layer Rigid プリント基板 (プリント基板) from UGPCB is a fundamental and widely used electronic interconnect solution. It features a standard 1.6mm board thickness, dimensions of 224.02mm x 189mm, and utilizes high-grade KB FR-4 laminate. This double-sided PCB serves as the essential “backbone” for electronic designs, providing reliable electrical connections and mechanical support for components. It is an ideal, cost-effective choice for a vast range of industrial control, 家電, and power supply applications.

設計上の重要な考慮事項

Successful design of a double-sided PCB requires balancing electrical performance with manufacturability. 主な考慮事項は次のとおりです。:

-

Routing Strategy: Efficiently utilize both top and bottom layers for trace routing. Plated Through-Holes (PTHs or Vias) enable inter-layer connections. Careful planning of trace density is crucial to prevent signal integrity issues like crosstalk.

-

Hole & Pad Design: Specify appropriate drill sizes and pad diameters for all PCB vias and component leads to ensure mechanical strength and soldering reliability, 順守 IPC標準 for annular ring.

-

力 & Ground Planes: While dedicated planes are absent, designers should widen power and ground traces or implement a gridded copper pour to reduce impedance and enhance stability—a key aspect of robust プリント基板設計.

-

デザインルールチェック (DRC): Prior to fabrication, rigorously verify that all parameters (trace width/clearance, hole sizes) align with the manufacturer’s capabilities (as per this board’s specs) to guarantee PCB design for manufacturability (DFM).

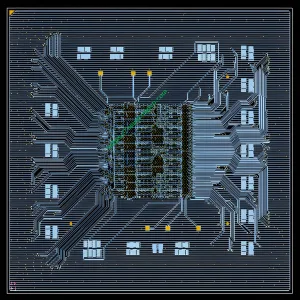

作業原則 & 構造

The functionality of this double-layer circuit board stems from its layered structure:

-

工事: The core consists of an FR-4 insulating dielectric layer, clad with copper foil (通常 1 オンス) on both sides. The unwanted copper is etched away during PCB製造, forming the desired circuit traces.

-

Electrical Interconnection: Circuits on the two layers are connected vertically via Plated Through-Holes (pths), created through mechanical drilling に続く electroless and electrolytic copper deposition.

-

Surface Protection: The Lead-Free Hot Air Solder Leveling (出血) finish applied to exposed copper pads prevents oxidation and ensures excellent solderability for component assembly.

製品分類 & 材料

Per the provided specifications, this product is accurately classified as follows:

-

レイヤーカウントごとに: 両面PCB または 2-レイヤーPCB.

-

By Substrate Rigidity: リジッドPCB.

-

ベース素材によって: FR-4基板. 具体的には, FR-4 from the “KB” brand, an epoxy glass laminate known for superior electrical insulation, 機械的強度, および火炎遅延 (UL94-V0).

-

表面仕上げによる: Lead-Free HASL PCB.

-

By Application Complexity: 標準, General-Purpose Industrial-Grade PCB.

パフォーマンス & 主な特長

Leveraging the specified materials and processes, this PCB delivers the following core performance benefits:

-

Reliable Mechanical & 電気性能: The KB FR-4 material offers stable dielectric constant and low dissipation factor for signal integrity. The 1.6mm standard thickness provides excellent resistance to bending and vibration.

-

Dependable Interconnections: The Lead-Free HASL surface finish アパートを提供します, highly solderable coating compatible with both wave soldering and hand soldering processes.

-

Superior Thermal Stability: FR-4 substrate withstands standard soldering temperatures and offers a high continuous operating temperature, suitable for most 産業用電子機器 環境.

-

High Cost-Effectiveness: Compared to multi-layer boards, double-sided PCBs offer significantly lower PCB fabrication cost and shorter lead times, representing an economical hardware solution.

-

Environmental Compliance: The 鉛フリーHASL process complies with international directives such as RoHS.

Detailed Manufacturing Process

UGPCB adheres to a stringent, high-standard PCB manufacturing process:

-

エンジニアリング & CAM: Gerber file analysis, DFM check, and photoplot generation.

-

Panelization: Cutting the large FR-4 銅張積層板 into production panels.

-

掘削: CNC drilling of component holes and PCB vias.

-

ホールメタライゼーション: デスミア, chemical copper deposition, and electrolytic copper plating to form conductive Plated Through-Holes (pths).

-

パターニング: フォトレジストの塗布, 暴露, development to transfer the circuit image.

-

エッチング: Removing unwanted copper to form precise circuit traces.

-

はんだマスク & シルクスクリーン: Applying LPI solder mask (typically green) and legend printing.

-

表面仕上げ: Applying 鉛フリーHASL coating to exposed pads.

-

Routing & 電気テスト: Profiling to final board outline and performing Electrical Test (飛行プローブ or Fixture Test).

-

最終検査 & 包装: Comprehensive 自動光学検査 (あおい), dimensional verification, and vacuum-sealed, moisture-proof packaging.

主要なアプリケーション & ユースケース

This specification of double-sided FR-4 PCB is widely deployed in reliable and cost-sensitive アプリケーション:

-

Industrial Control Systems: PLC controllers, motor drive boards, sensor interface modules.

-

Power Supply Units: Switch-mode power supplies (SMPS), UPS systems, LED driver boards.

-

家電: Appliance control boards (AC, washing machines), smart home controllers, オーディオ機器.

-

カーエレクトロニクス: Body control modules (BCM), lighting controllers, non-critical infotainment systems.

-

Telecommunications Equipment: Functional modules within routers, スイッチ.

-

テスト & 測定器: Data acquisition and display panels for equipment.

Why Choose UGPCB for Your Double-Sided PCB Needs?

Partnering with UGPCB guarantees:

-

精密製造: Strict adherence to 1.6mm thickness, 224.02x189mm dimensions, そして FR-4材 仕様.

-

Process Excellence: Standardized Lead-Free HASL PCB production ensures batch-to-batch consistency and reliability.

-

Expert Technical Support: Our team provides comprehensive support, から プリント基板設計 レビュー to production consultation.

-

Fast Turnkey Delivery: We offer competitive lead times for standard double-layer PCB prototypes and production runs.

Ready to start your project? Contact UGPCB today for a competitive quote and expert support. Let us be your trusted PCBメーカー and partner for success.

UGPCBのロゴ

UGPCBのロゴ