Radio Signals Traverse Invisible Airwaves, impulsado por PCB de RF Sometido a una evolución tecnológica silenciosa pero transformadora.

El rápido avance de la comunicación de alta frecuencia es impulsar la tecnología PCB RF a una nueva era. La implementación de infraestructura global 5G acelera, La adopción del espectro de onda milimétrica se expande, y la proliferación de dispositivos IoT crece exponencialmente, todos exigen un rendimiento sin precedentes de los circuitos de RF.

Los materiales FR-4 tradicionales luchan con requisitos de alta frecuencia, mientras que innovaciones como los transistores de grafeno, polímero de cristal líquido (LCP) sustratos, y los adhesivos de curado a baja temperatura están empujando los límites físicos. Al mismo tiempo, PCB rígido-flexibles ahora lograr 100,000+ ciclos de curvatura, Los circuitos flexibles alcanzan el espesor de 0.05 mm, y la producción de FPC personalizada se vuelve factible: los avances de fabricación que permiten la electrónica portátil e innovaciones de vehículos de nueva energía.

1. Revolución material: Romper las barreras de alta frecuencia

RF PCB Rendimiento Bisagras en las propiedades del material del núcleo. A frecuencias de onda milímetro (>30GHz), constante dieléctrica (Dk) y factor de disipación (df) convertirse en parámetros de selección crítica que determinan la eficiencia de la transmisión de la señal.

FR-4 tradicional (Dk≈4.3, Df≈0.02) exhibe pérdidas significativas por encima de 10 GHz, fallando 5G/demandas de radar. Las soluciones de la industria ahora incluyen:

-

Transistores de grafeno RF: Los sustratos flexibles ahora admiten dispositivos de frecuencia de corte de 39 GHz. Alcanza la movilidad del transportista 2,500 cm²/v · s con <10% Degradación del rendimiento después de 1,000 ciclos de curvatura (CEI 60340 estándar).

-

Sustratos LCP: Preferido para wearables, LCP Hybrid Flex Circuits alcanza >90% transmitancia y radio de curvatura de 3 mm con durabilidad de 100,000 veces. Propiedades eléctricas superiores (DK = 2.9-3.1, DF = 0.002-0.004) Explorar materiales convencionales.

-

Adhesivos de baja temperatura: Las nuevas formulaciones epoxi cura a 80-120 ° C (30% más bajo que los procesos tradicionales), extender la vida de la plantilla a 8,000+ Impresiones al tiempo que reduce los costos de producción por 18%. Ideal para mini envases LED y circuitos flexibles automotrices.

Comparación de material PCB de alta frecuencia

| Material | Dk | df | Frecuencia máxima | Factor de costo |

|---|---|---|---|---|

| Estándar FR-4 | 4.3-4.8 | 0.018-0.025 | <5GHz | 1.0incógnita |

| Rogers 4350b | 3.48±0,05 | 0.0037 | 30GHz | 8.5incógnita |

| Con sede en PTFE | 2.8-3.0 | 0.0009-0.002 | 77GHz | 12incógnita |

| LCP | 2.9-3.1 | 0.002-0.004 | 110GHz | 15incógnita |

| Compuesto de grafeno | 2.3-3.5 | 0.0005-0.001 | >100GHz | 20x+ |

2. Avances de diseño: Densidad de redefinición & Eficiencia

La miniaturización del dispositivo exige el espacio optimizado Diseños de PCB de RF:

-

Circuitos flexibles ultra delgados (0.05milímetros) aumentar la densidad de cableado por 50%, habilitador 20% Reducción de volumen en Tesla 4680 batería.

-

Las tablas HDI Rigid-Flex alcanzan 20/20 μm de rastreo/espacio con rendimiento de 56 Gbps (p.ej., Sensores de seguimiento ocular de Apple Vision Pro), Uso de láser de back-shilling para controlar los trozos <50μm.

-

Innovaciones de gestión térmica: La poliimida nanomodificada soporta 300 ° C y voltaje de desglose de 1200 V para plataformas de 800V EV.

*”Contornos de PCB de flexión rígida a curvas de reloj inteligente, Mejora de la utilización del espacio en un 40%” - Huawei Watch GT4 Design Team*

3. Fabricación: La precisión cumple con la inteligencia

-

Imágenes directas láser (LDI): Habilita anchos de línea de 5 μm con 92% producir, triplicar la eficiencia de exposición tradicional.

-

Procesamiento gradual: Combina el corte con láser grabado para una precisión dimensional de ± 2 μm (01005 compatible compatible).

-

Inspección visual de IA: 99.9% Reconocimiento de defectos para fallas a nivel de micrones, Mejorar la confiabilidad al tiempo que reduce los costos.

4. Aplicaciones: Portátiles para vehículos eléctricos

Tecnología portátil

Los PCB de flexión rígida dominan el mercado portátil de $ 150B:

-

Pantalones de yoga de Lululemon con PCB flexes de detección de presión

-

Apple Watch Ultra ECG Connections (500Velocidad de datos de MBPS)

-

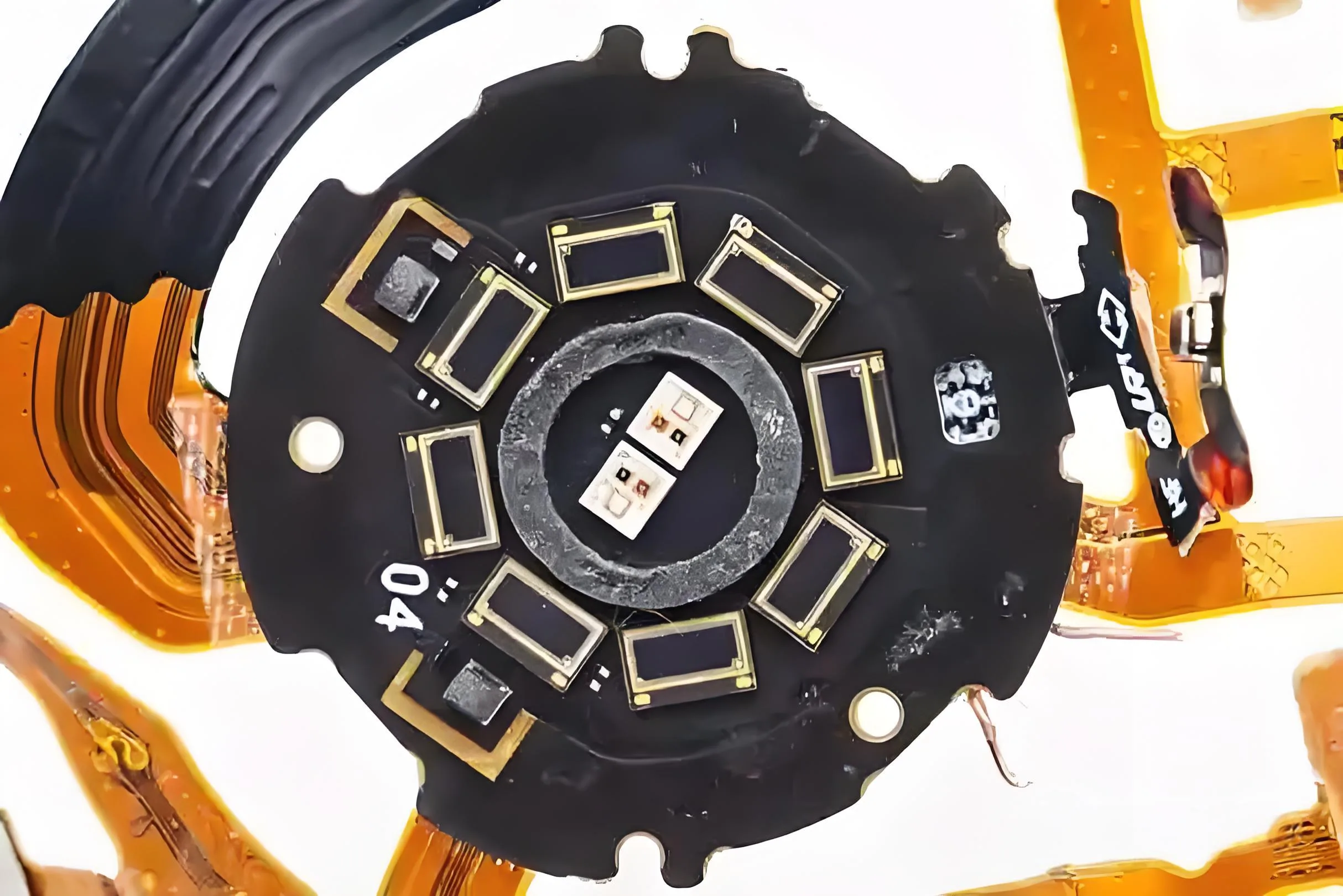

Meta misión 4 Tablas de HDI integrante 12 cámaras + 5 radares mmwave

Electrón electrónica

Soluciones de Flex Automotive de BYD:

-

FPCS BMS con monitoreo de células de 100k/seg

-

Módulos de ECG del volante (95% exactitud)

-

Circuitos listos para THZ para 6G V2X (0.1Objetivo de latencia de MS)

Sistemas de alta frecuencia

Los transistores de grafeno RF habilitan 39GHz 5G/6G Estaciones base. Las tintas conductoras reducen el efecto de la piel, mientras que los compuestos de grafeno-cobre mejoran la resistencia a la corrosión.

5. Tendencias futuras: Convergencia & Adelanto

-

Componentes incrustados (IPD): 01005 Integración de componentes Tamaño de la placa 40% Al mejorar la integridad de la señal.

-

Sistemas autopotencias: Nanogeneradores triboeléctricos (Teng) cosecha de energía cinética; Las interfaces cerebrales de estilo neuralink permiten vehículos controlados por el pensamiento.

-

Fabricación sostenible: Las tintas a base de agua y la soldadura sin plomo reducen los desechos por 40%. Tasas de reciclaje de cobre >95% apoyo “FPC de carbono cero” objetivos por 2030.

*Los científicos de materiales predicen: “Los compuestos metálicos de grafeno-líquido violarán las barreras de 100 GHz por capas físicas 6 g.”*

6. Conclusión

RF PCB Advancements Span Materials (Grafeno/LCP), diseño (3D Integración), y fabricación (AI/LDI). Estas innovaciones impulsan la infraestructura 5G, dispositivos portátiles, y rendimiento de EV.

Con implementaciones de 5G/MMWAVE y crecimiento de IoT, demanda de Proveedores de PCB de alta frecuencia se intensificará. Líderes de la industria como UGPCB Continuar desarrollando soluciones patentadas en materiales avanzados y tecnologías de circuito flexible.

UGPCB LOGO

UGPCB LOGO