Imagem de circuito de precisão & Tecnologia de Gravura

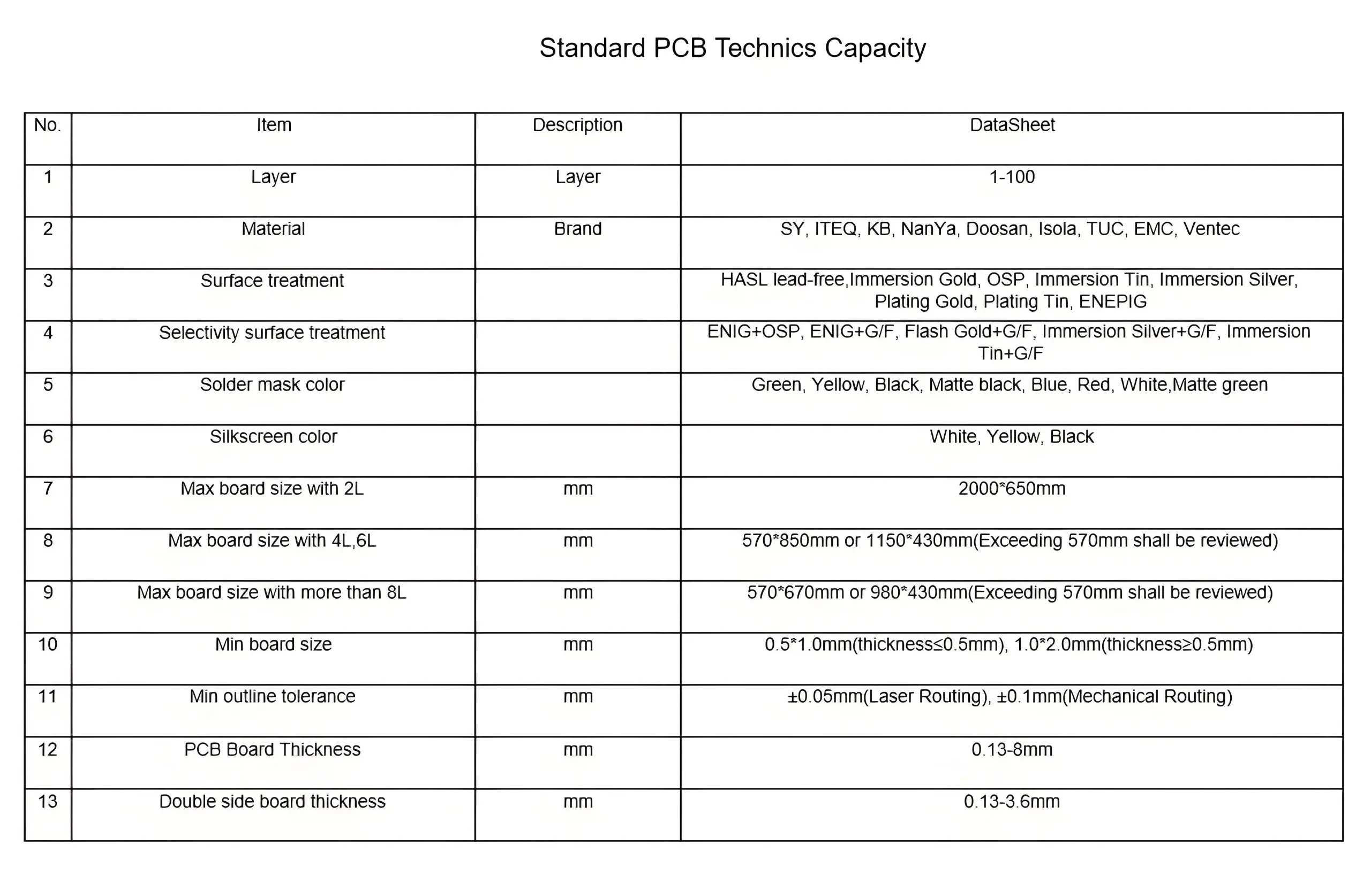

Fábrica UGPCB demonstra controle de processo excepcional em padronização e gravação de circuitos. Para produção de PCB padrão, alcançamos consistentemente:

- Imagem direta a laser (Ldi) substituindo máscaras tradicionais de fotolitografia, permitindo exposição baseada em arquivo digital com precisão de alinhamento de ±5μm

- Processo de gravação alcalina garantindo bordas de linha limpas com controle de largura de linha de ±15% (tolerância líder do setor)

- Experiência no manuseio de diversas espessuras de cobre (1Oz-6oz) com gravação lateral minimizada

Perfuração de alta precisão & Metalização de furo

Nossas capacidades de perfuração abrangem:

- Perfuração mecânica para placas de 0,4 mm a 3,0 mm com tolerância de tamanho de furo de ± 0,025 mm

- Perfuração a laser até microvias de 0,1 mm

- Metalização de furo alcançando >20revestimento de cobre uniforme μm através de deposição química avançada e galvanoplastia

- Processos especiais para 8:1 para 10:1 requisitos de proporção

Laminação multicamadas & Alinhamento Intercalar

- Fabricação de PCB de até 100 camadas usando materiais FR-4 Grau A

- Precision lamination with ±15um layer-to-layer alignment

- Processos controlados por temperatura/pressão/tempo que evitam a delaminação

- Opções para materiais de alta Tg, laminados de alta velocidade, e cobre pesado até 1000μm

Máscara de solda & Opções de acabamento de superfície

- Cores da máscara de solda: Verde/Azul/Vermelho/Preto com ponte de solda mínima de 0,08 mm

- Acabamentos de superfície:

- Sangrar (Nivelamento de solda com ar quente)

- CONCORDAR (Ouro de imersão em níquel eletrolítico)

- Imersão em estanho/prata

- OSP (Conservador de solda orgânica)

Controle de qualidade abrangente & Sistemas de teste

- AOI Inspeção: Detecção de defeitos de alta resolução para linha/espaço, almofadas, shorts/abertos

- Controle de impedância: Tolerância de ±10% para aplicações de alta velocidade/RF

- Teste elétrico: Sonda voadora & verificação de continuidade baseada em acessórios

- Teste de confiabilidade: Choque térmico, resistência à umidade, testes de flexão

Capacidade de Processo & Estabilidade

- CPK >1.33 (4um) em processos críticos, alcançando 1.67 (5um) em áreas-chave

- Controle de largura de linha dentro de ±15% (versus indústria 20% padrão)

- Controle estatístico de processo (Spc) garantindo qualidade de produção consistente

Serviços completos PCBA

- Montagem SMT: 01005 manuseio de componentes com precisão de posicionamento de ±0,03 mm

- Embalagem Avançada: Suporte BGA/Micro BGA/PoP com inspeção por raios X

- Suporte DFM: Cálculo de impedância, projeto de empilhamento, análise de capacidade de fabricação

Aplicações do setor & Contato

Servindo produtos eletrônicos de consumo, controles industriais, telecomunicações, dispositivos médicos, e setores automotivos com soluções de PCB personalizadas. Visite nosso site para obter relatórios de capacidade de processo e consulta gratuita de DFM.

LOGOTIPO UGPCB

LOGOTIPO UGPCB

WeChat

Digitalize o código QR com WeChat