ในการประกอบ SMT, ข้อบกพร่องระดับไมครอนอาจทำให้คุณภาพลดลง. สำหรับ พีซีบี designers and พีซีบี production managers, ลูกประสานแบบถาวรบนแผ่นส่วนประกอบชิป (เช่น ตัวต้านทาน และตัวเก็บประจุ MLCC) เป็นปัญหาทั่วไป. These defects affect aesthetics and can cause short circuits in demanding applications, threatening product reliability. This guide analyzes the five root causes of solder balls and provides a systematic, IPC-based solution framework to enhance soldering yield.

The Core Mechanism: Paste Squeeze and Failed Containment

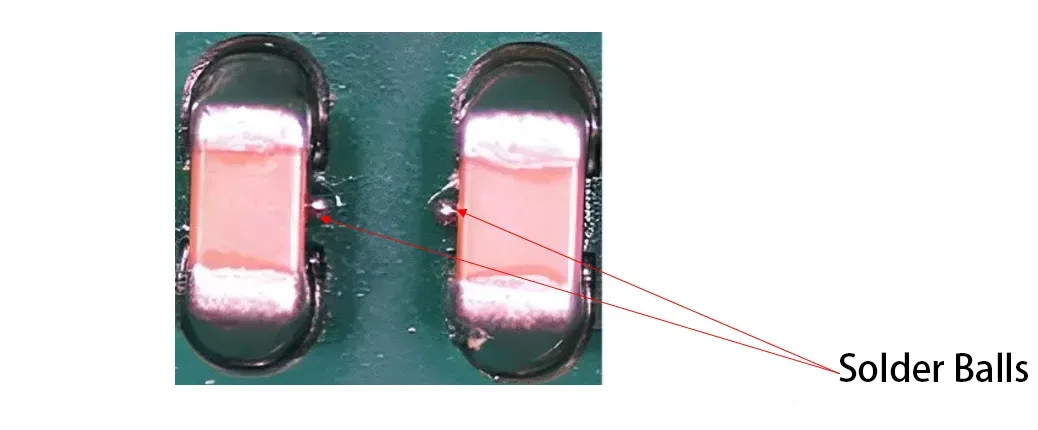

ลูกประสาน “escape” rather than “form.” During reflow, molten solder paste fails to coalesce into the main joint due to surface tension, separating and balling up at the pad edges. Per IPC-A-610, a solder ball is a defect if its diameter exceeds 0.13mm or if it risks bridging conductors.

The primary cause is solder paste being squeezed onto the solder mask during printing or placement. The non-wettable solder mask prevents paste from rejoining the main joint, forming independent balls.

Root Cause 1: การออกแบบพีซีบี “Topography”

การออกแบบ PCB is the first defense. Poor pad and solder mask design creates escape routes.

1. Solder Mask Dams: To Keep or Remove?

Traditional solder mask dams between adjacent Chip pads prevent bridging but create paste-trapping trenches. Removing the dam eliminates this terrain, allowing paste to deposit cleanly on the pad for unified surface tension control during reflow.

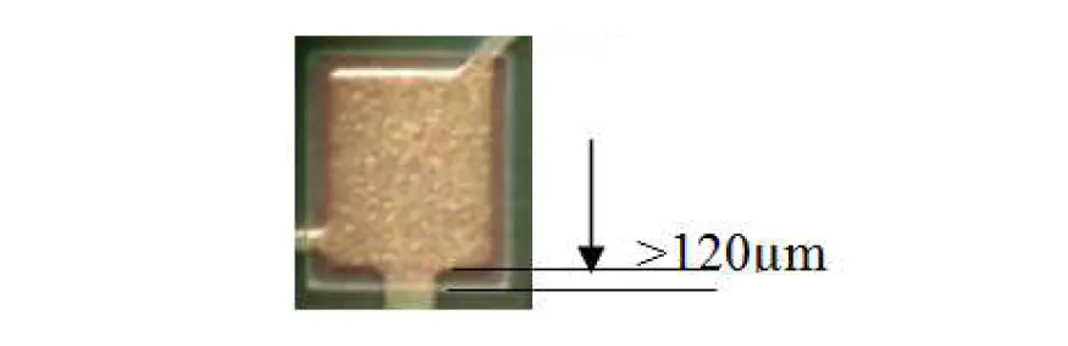

2. Solder Mask Opening (เอสเอ็มดี): Ensure Adequate Buffer

The SMD must be larger than the copper pad. IPC-7351 recommends a minimum 75µm (3MIL) single-side gap for Chip components, with 120µm (5MIL) as best practice. This buffer accommodates minor solder mask misalignment, ensuring paste contacts only the wettable copper.

3. Manage Manufacturing Tolerances

Collaborate with your PCB supplier. Specify stringent solder mask alignment tolerances (typically ≤50µm) and choose a supplier capable of meeting them within your design’s buffer zone.

Root Cause 2: Stencil Design “Dosage Control”

ที่ stencil dictates paste volume and shape.

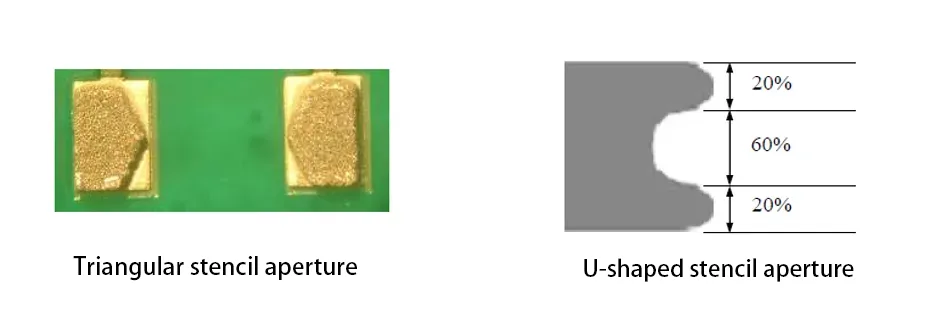

1. Volume Reduction & Shaping: U-Shaped/Triangular Apertures

สำหรับ 0402 and larger components, reduce paste volume. Advanced designs use U-shaped or triangular apertures instead of squares. This reduces center volume while directing paste to the pad ends, providing sufficient solder while minimizing squeeze-out. This can reduce paste volume by 15-20%.

2. Optimize Aperture Ratio

Stencil aperture width is typically 80-90% of the pad width. Ensure an Area Ratio > 0.66 for clean release and precise volume control.

Root Cause 3: Pursuing “Zero Gap” in Paste Printing

Printing defines initial paste placement.

1. Achieve True Zero-Gap Contact

Any stencil-PCB gap causes paste bleed under squeegee pressure. Ensure a flat support platform and optimal pin placement for uniform PCB backing. Calibrate machine parallelism regularly.

2. Maintain Cleaning and Alignment

Dried paste on the stencil bottom creates gaps. Implement frequent bottom-side wiping (เช่น, ทั้งหมด 5-10 boards for fine-pitch components). Use high-precision vision alignment for perfect stencil-to-pad registration.

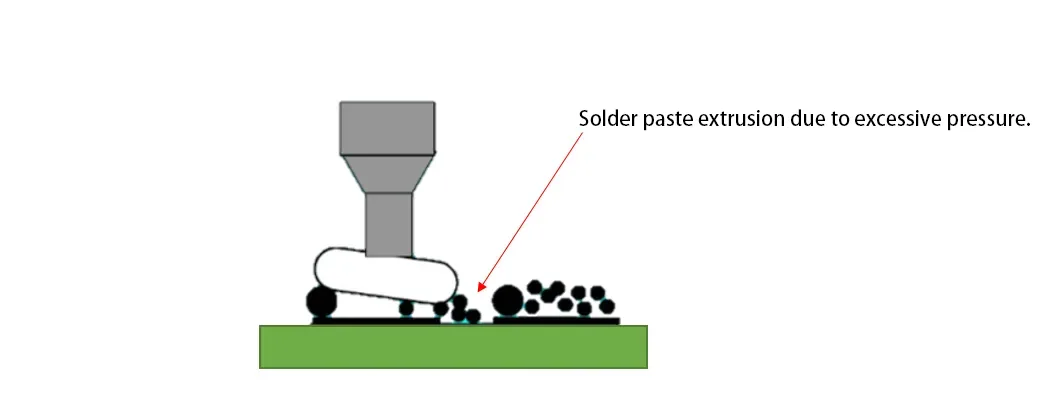

Root Cause 4: “Gentle” ตำแหน่งส่วนประกอบ

Placement can crush paste.

Excessive Z-force or low placement height squeezes paste out. Set the component placement height ถึง 1/2 ถึง 2/3 of the post-print paste height. This allows the part to “kiss” the paste without impact.

Root Cause 5: Reflow “Thermodynamic” ควบคุม

The reflow profile, especially preheat, เป็นสิ่งสำคัญ.

1. Avoid Extended Preheat and “Hot Slump”

Long soak zones can cause “hot slump”: premature flux evaporation/viscosity drop makes paste slump and spread onto the solder mask before melting, leading to ball formation.

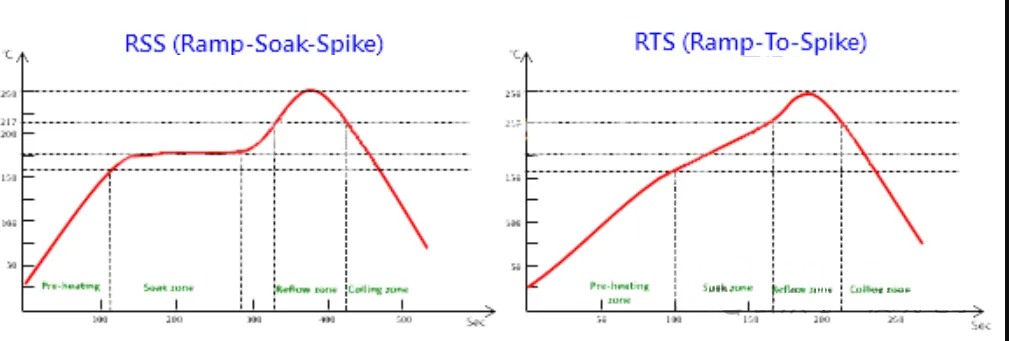

2. Use a Ramp-to-Peak or Linear Profile

Shorten or eliminate the soak plateau. Use a controlled linear ramp from ambient to peak, with a preheat rate of 1.0-2.0°C/sec. This reduces low-temperature dwell time, limits slump, and allows synchronous melting for effective surface tension pull.

Data Point: Per IPC/JEDEC J-STD-020, for SAC305 solder, เป้า 60-90 seconds above liquidus (TAL) and a 235-245°C peak. Optimize the preheat slope within these constraints.

บทสรุป: A Systemic Optimization Approach

Solving Chip component solder balls requires a system engineering approach across การออกแบบ PCB, stencil fabrication, SMT printing, component placement, และ reflow soldering.

Checklist for Solder Ball Reduction:

-

การออกแบบพีซีบี: Are solder mask dams removed? Are SMD openings ≥120µm?

-

Stencil Design: Are U-shaped/triangular apertures used? Is the aperture ratio correct?

-

Printing Process: Is stencil cleaning frequent? Is alignment accuracy high?

-

Placement Program: Is placement height set to 1/2 – 2/3 of paste height?

-

โปรไฟล์การรีมอน: Can you implement a linear ramp with a controlled preheat rate?

For high-reliability products, engage a professional ผู้ผลิต PCBA สำหรับ ออกแบบเพื่อการผลิต (DFM) review early on. An experienced EMS partner can identify risks and provide proven solutions. Through collaborative design and process control, solder balls can be minimized to within IPC acceptability limits, achieving higher first-pass yield and superior board reliability.

โลโก้ UGPCB

โลโก้ UGPCB

I like the helpful information you provide to

your articles. I will bookmark your weblog and check again here regularly.

I am fairly sure I will be told many new stuff proper right here!

Best of luck for the next!

It’s in reality a nice and helpful piece of information. I’m satisfied that you just

shared this helpful info with us. Please keep us up to

date like this. Thanks for sharing.

Pretty! This has been an incredibly wonderful

article. Many thanks for supplying this information.

Thanks for ones marvelous posting! I certainly enjoyed reading it, you are a great author.

I will always bookmark your blog and definitely will come back in the future.

I want to encourage yourself to continue your great writing, have a

nice afternoon!

I have been surfing on-line more than 3 hours today, but I never discovered any interesting article like yours.

It is pretty worth sufficient for me. In my view, if all site owners and bloggers made good content as you probably did, ที่

web will be much more helpful than ever before.

สวัสดี, i think that i saw you visited my blog so i came to return the prefer?.I’m trying

to find issues to enhance my web site!I suppose its ok to use a few of your

ideas!!

This is my first time pay a visit at here and i am genuinely pleassant to read all at alone place.