UGPCB: Pioneering High-Density Interconnect Innovation with Advanced HDI PCB Technology

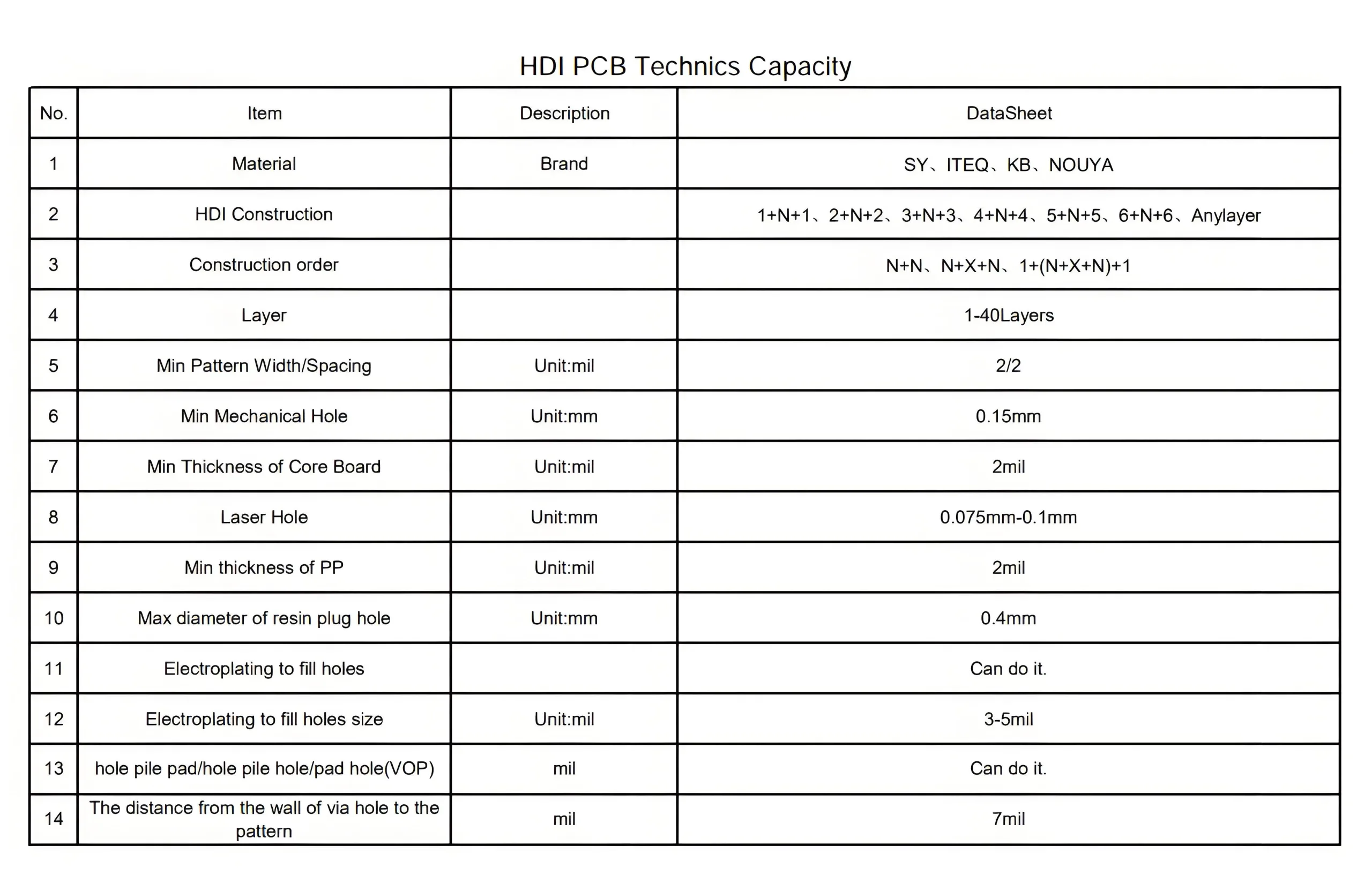

Industry-Leading HDI PCB Manufacturing Capabilities

UGPCB stands at the forefront of IDH (Interconexión de alta densidad) tecnología de PCB, driving progress in an era where electronic devices demand unprecedented thinness and functionality. Specializing in 4-40 layer multilayer boards with thickness ranging from 0.4mm to 6.0mm, we cater to diverse needs from consumer electronics to premium communication equipment.

Our cutting-edge Any-layer HDI technology enables seamless interconnection across over 10 tarjeta de circuito impreso capas, delivering robust connectivity solutions for high-performance computing and communication devices. This capability positions us as a trusted partner for next-generation electronic applications.

Process Technology: Precision Meets Reliability

Equipo avanzado & Innovación

UGPCB sets industry benchmarks in HDI PCB manufacturing through state-of-the-art equipment and process innovation:

- Perforación láser: Achieves microvia processing as small as 0.075mm (3mil) with precision exceeding industry standards

- Tecnología de microvia: Hidden interconnections through next-layer vias eliminate fan-in/fan-out routing, significantly enhancing circuit density

- Control de impedancia: Maintains +/-7% impedance tolerance for superior signal integrity in 5G and high-performance computing applications

Comprehensive Manufacturing Process

Our HDI production workflow integrates:

- Perforación láser: CO₂ laser systems ensure consistent hole quality and cleanliness

- Plating Process: 12-18μm copper thickness guarantees electrical reliability

- Pattern Transfer: Supports 1.5/1.5mil minimum line width/spacing for ultra-dense routing

- Lamination Technology: Layer alignment accuracy within ±200μm ensures structural stability

We utilize high-performance PCB substrates including high-Tg FR-4 (140/150/170℃) and polyimide materials to ensure stable performance in high-temperature environments.

Seguro de calidad & Testing Systems

Multi-Layered Inspection Protocols

UGPCB implements rigorous quality control through:

- AOI (Inspección óptica automática)

- Flying Probe Testing

- X-ray Inspection

Microvia Reliability

The inherent reliability of our microvia technology stems from:

- Thinner construction with 1:1 relación de aspecto

- Superior signal transmission stability compared to traditional through-holes

- Enhanced long-term durability for demanding applications

Aplicaciones: Empowering Cutting-Edge Technologies

UGPCB’s HDI PCBs power high-tech applications across multiple sectors:

- 5G Communication: High-frequency PCBs for 5G base stations and RF modules

- Electrónica automotriz: Stable signal transmission for navigation and entertainment systems

- Dispositivos médicos: Precision data acquisition for patient monitors and surgical instruments

- Controles Industriales: Efficient data exchange for PLCs and sensor networks

Ventajas técnicas: Por qué elegir UGPCB?

Superior Performance Features

- Eficiencia del espacio: Microvia/blind via designs reduce PCB footprint by up to 30%

- Integridad de señal: Low-DK materials minimize signal delay and crosstalk for high-speed transmission

- Design Flexibility: Enables complex circuits in compact spaces

- Gestión Térmica: Dedicated thermal layers improve heat dissipation for high-power applications

R&D Direction & Perspectiva futura

Next-Gen Technology Investment

UGPCB actively develops HDI PCBs with:

- Higher density and finer lines

- Lower signal loss characteristics

- Laser drilling advancements

- Nanomaterial integration

- Smart manufacturing systems

Our R&D team focuses on advanced microvia technologies and material innovations to support client roadmaps for 5G, AI, and IoT devices.

Conclusión: Your Trusted HDI PCB Partner

Liderazgo de la industria

As an HDI PCB technology leader, UGPCB delivers:

- Advanced process capabilities

- Stringent quality control

- Continuous technological innovation

Comprehensive Solutions

From smartphones to automotive systems, we provide total high-density interconnect solutions. Choosing UGPCB means selecting:

- Superior performance

- Reliable quality

- Technological foresight

Contact UGPCB today to explore how our HDI PCB technology can empower your next-generation products.

UGPCB LOGO

UGPCB LOGO

WeChat

Escanea el código QR con WeChat