La batalla de vida o muerte en microelectrónica: Reacción en cadena inducida por la brecha de máscara de soldadura

Con 0201 componentes y bgas de tono de 0.3 mm que se convierten en la corriente principal, tarjeta de circuito impreso tarifas de omisión de soldadura han surgido 37% (PCI 2023 datos). De acuerdo con un estudio de una década por UGPCB: 60% de defectos SMT se originan en la falla de transferencia de pasta, dónde brechas de impresión de micro almohadillas actuar como los pasados por alto “asesino invisible”.

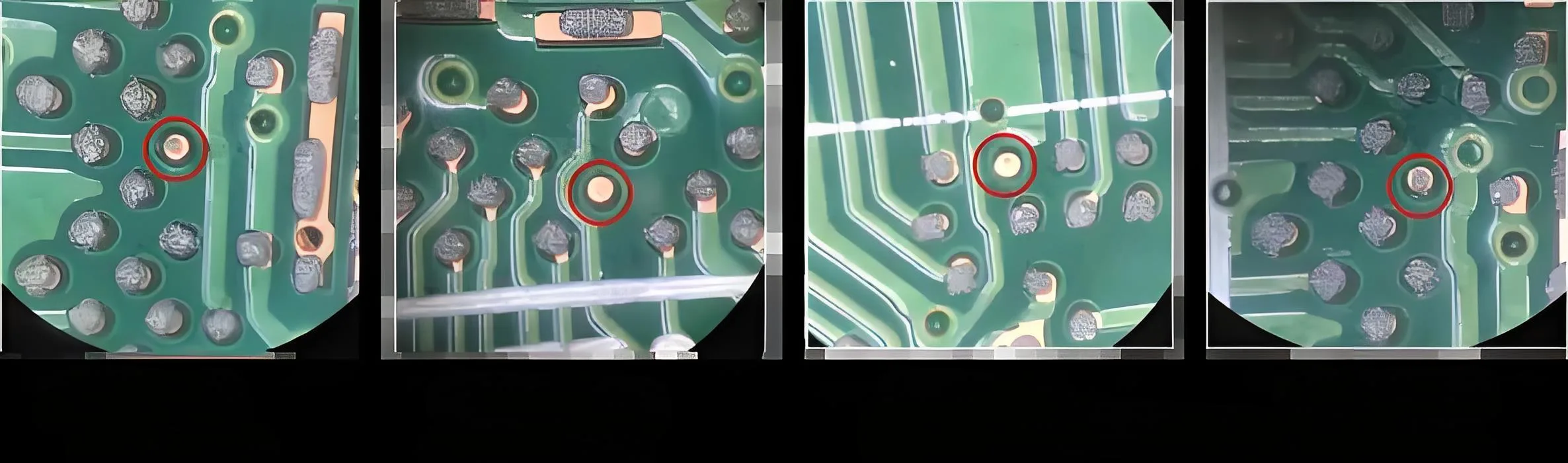

Lecciones escritas en sangre: La micrografía revela puntos de dolor de la industria

-

Máscara de soldadura a la altura de la almohadilla de cobre: 35μm

-

Aperture de plantilla que cubre el área de sustrato: 42%

-

Área de contacto de pasta de soldadura efectiva: <58%

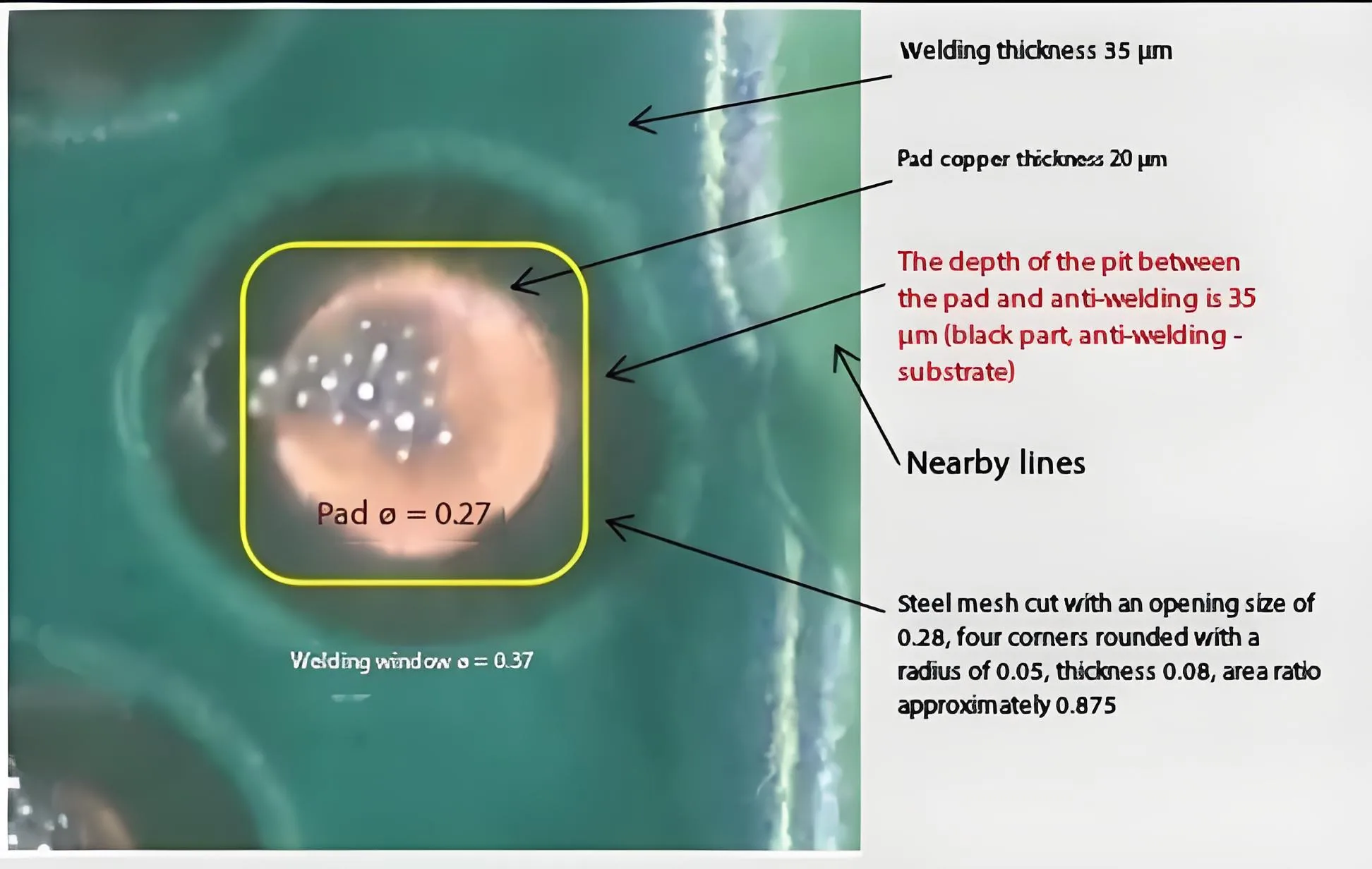

Física detrás del fracaso: Lo matemático “Triángulo de la muerte” de transferencia de pasta

Fórmula fatal: El colapso de la teoría de la relación de área IPC-7525

Relación de área = (L × W) / [2H(L+W)]

La teoría tradicional falla cuando el diámetro de la almohadilla ≤0.3 mm! Los datos empíricos de los principales fabricantes revelan:

| Diámetro de la almohadilla (milímetros) | Relación teórica | Tasa de transferencia real |

|---|---|---|

| 0.40 | 0.68 | 92% |

| 0.31 | 0.61 | 85% |

| 0.27 | 0.55 | 63% |

Dinámica de fluidos expuesto: Por qué la pasta de soldadura “Rechazado” Almohadilla

Cifra 2: Simulación de tensión fluida durante la liberación de plantilla

Alternativo: Análisis de tensión de la pared de la plantilla de pasta de soldadura – Simulación de defectos de impresión PCBA – Soluciones SMT

Hallazgos críticos:

-

Los huecos de máscara de soldadura crean efecto de cojín de aire, Reducir el área de contacto por 41%

-

El salto de soldadura ocurre cuando la cohesión de pasta > adhesión

Soluciones de grado industrial: Tres pilares para eliminar la soldadura omitiendo

Revolución del diseño de la almohadilla: Principio de expansión del cobre

-

Diámetro aislado de la almohadilla: 0.27mm → 0.31 mm

-

Cobertura de brecha reducida a 12%

-

La tasa de transferencia aumentada a 89% (datos empíricos)

Máscara de soldadura “Adelgazante” Iniciativa: El estándar de oro de 25 μm

Cifra 3: Comparación de impresión con diferentes espesores de máscara de soldadura

Alternativo: Comparación de espesor de máscara de soldadura de PCB – Mejora del rendimiento de SMT – Guía de proveedores de PCBA

Fórmula de grosor: H = (RZ + d) × K (δ = Tamaño de partícula de pasta, Tipo 4: 25μm; K = factor de seguridad 1.2)

Validación de la industria: El fabricante de PCB móvil redujo el grosor de 35 μm a 22 μm → 82% Reducción en el salto de soldadura de QFN

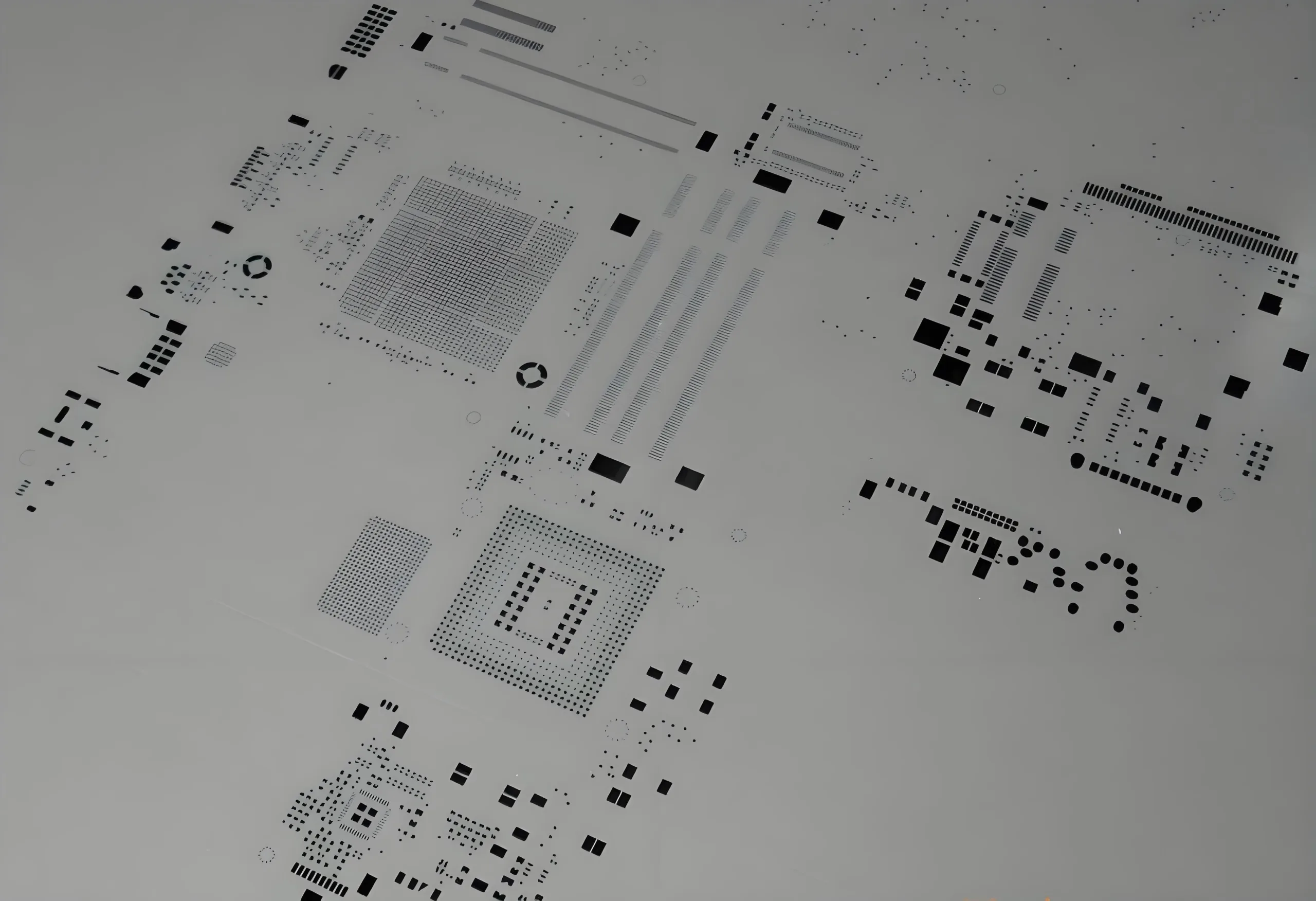

Plantillas de ph: La mejor solución de nano-conformidad

Innovación:

Innovación:

-

Diseño de apertura escalonada: Ángulo de pared de 7 ° a 15 °

-

Níquel electroformado: 3x aumento de dureza

-

Ángulo de asistencia de demoldización: 40% fricción de pared reducida

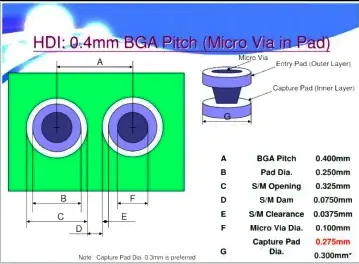

Líderes de la industria’ Libro de jugadas: IDH + Norma de oro NSMD

Estrategia de precisión de la industria móvil

Caso: 0.4MM Pitch BGA Process Blueprint 1. Reemplace la impresión de leyenda → diseño de cobre desnudo 2. Implementar IDH Microvias 3. Grosor de la máscara de soldadura: 18± 3 μm (Clase IPC-6012 3 obediente)

Motor de conversión: Su plan de acción de actualización de fábrica

Lista de verificación de ejecución inmediata:

-

Auditar todas las almohadillas aisladas: Rediseño si diámetro <0.3milímetros

-

Demanda de los informes de grosor de máscara de soldadura de Proveedores de PCB (Métrica clave: ≤25 μm)

-

Adquirir plantillas de pH con urgencia: 55% ganancia de eficiencia de apertura en áreas de lanzamiento fino

UGPCB LOGO

UGPCB LOGO