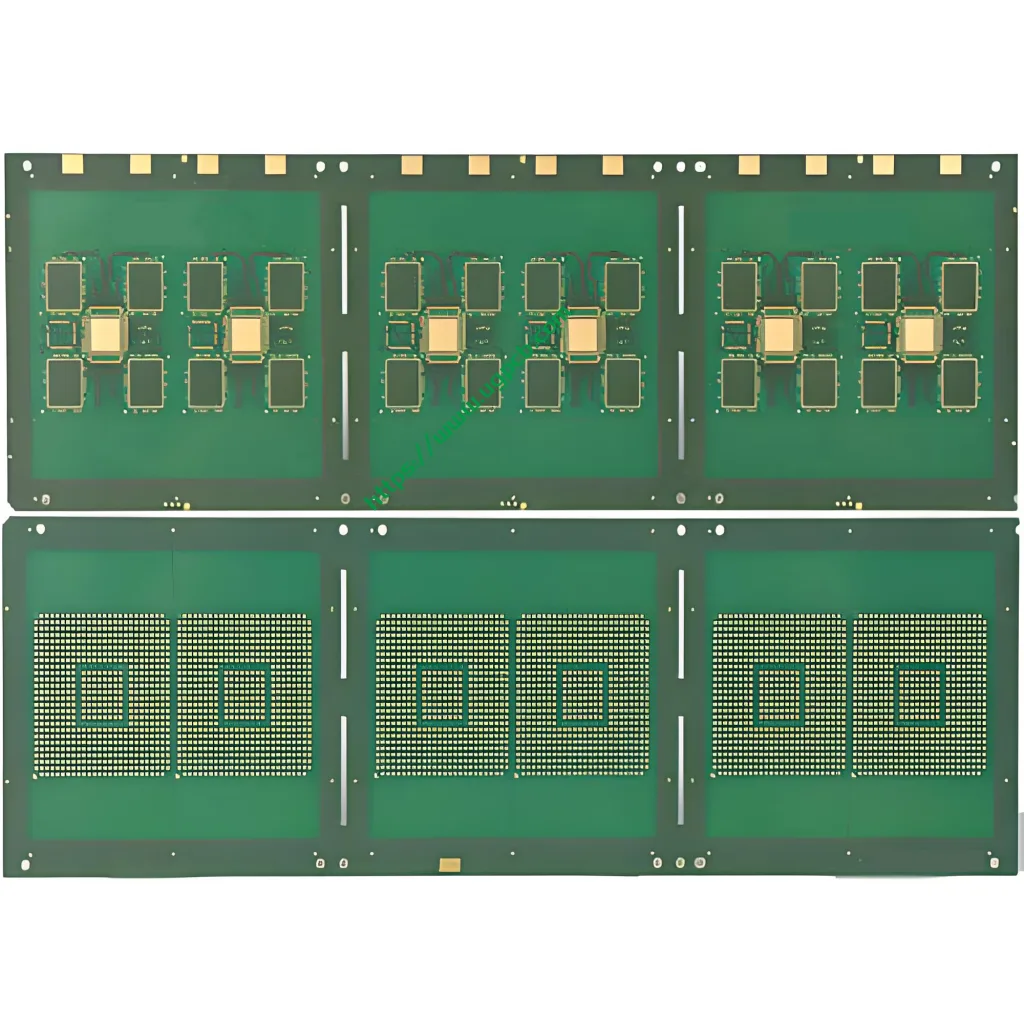

UGPCB: High-Density Blind Vias IC Substrate for Advanced Semiconductor Packaging

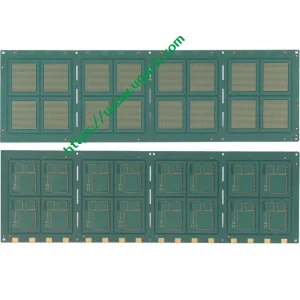

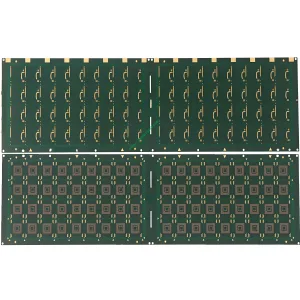

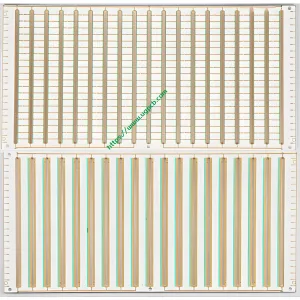

UGPCB’s 8-layer Blind Vias IC Substrate, built with Mitsubishi Gas HF HL832NX material, enables superior signal integrity and high-density interconnects for next-generation chips, featuring 30μm line width and 0.1mm micro vias.

As electronics rapidly evolve toward miniaturización, mayor densidad, and enhanced performance, traditional through-hole via technology struggles to meet the demands of modern chip packaging. Blind Via technology has emerged as a critical solution for Interconexión de alta densidad (IDH) diseño.

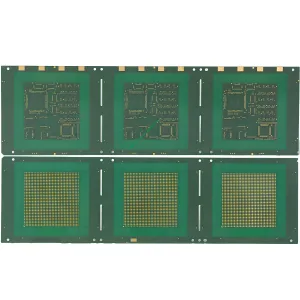

A Blind Via is a conductive hole that connects an outer layer of a PCB to one or more inner layers without passing through the entire board. UGPCB’s 8-Layer Blind Vias IC Substrate, utilizing Mitsubishi Gas HF material, exemplifies this advanced technology, providing a precision, reliable interconnection platform for advanced semiconductor packaging.

Core Product: In-Depth Look at Blind Vias IC Substrates

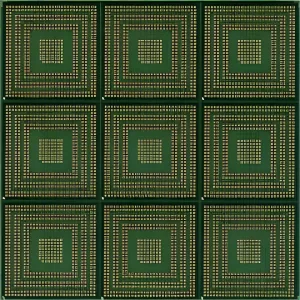

Blind Via technology defines a specific type of interconnect structure that connects an outer layer to an adjacent inner layer only. Unlike a through-hole via, a blind via starts on the board surface and terminates precisely at a specific inner copper layer.

This structure maximizes usable wiring space by eliminating unnecessary through-board holes, significantly increasing circuit density—a perfect match for the industry’s drive toward smaller form factors and greater integration.

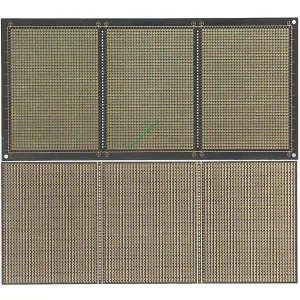

From a technical implementation perspective, the design and fabrication of blind vias adhere to strict standards, such as those outlined in the IPC-6012 qualification and performance specification for rigid PCB. They are typically formed using laser drilling processes, creating a tapered hole structure. This allows for precise control over depth and diameter, meeting the stringent requirements of advanced packaging for micro-features and registration accuracy.

Especificaciones técnicas & Design Advantages

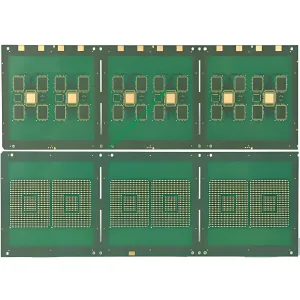

The design of UGPCB’s Blind Vias IC Substrate is highly specialized, involving critical considerations from material selection to stack-up architecture.

Key Technical Parameters:

-

Modelo: Blind Vias IC Substrate

-

Material central: Mitsubishi Gas HF (HL832NX) BT Epoxy

-

Recuento de capas: 8 capas

-

Overall Thickness: 0.6 milímetros

-

Board Dimensions: 40 mm x 55 milímetros

-

Máscara de soldadura: PSR-4000 AUS308

-

Acabado superficial: Soft (Electroless Nickel Immersion) Oro

-

Minimum Laser Drilled Via Diameter: 0.1 milímetros

-

Minimum Line Width / Espacio: 30 μm / 30 μm

This substrate employs Japan’s Mitsubishi Gas Chemical HF series BT material (HL832NX), known for excellent dielectric properties (Dk/Df) y estabilidad térmica, making it ideal for high-frequency and high-speed applications. El 30μm fine line technology is critical for connecting high-pin-count chips, while the ENIG surface finish provides a flat, wire-bondable, and reliable soldering surface.

How It Works: Precision Interconnection & Integridad de señal

The core function of a Blind Vias IC Substrate is to establish efficient, reliable interlayer electrical connections while minimizing real estate consumption—directly addressing modern packaging needs for high density and superior performance.

For signal transmission, blind vias offer distinct advantages over through-hole vias. Through-holes can create unwanted stubs that act as antennae, degrading signal integrity at high frequencies. Vias ciegos, connecting only necessary layers, eliminate these non-functional stubs, reducing parasitic capacitance and inductance for cleaner, more stable signal paths.

The fabrication typically uses controlled-depth laser drilling, offering superior precision and consistency for micro-vias compared to mechanical drilling. This is crucial for maintaining high yield and quality in volume production.

Regarding signal integrity, the 30μm line/space design, combined with the optimized dielectric material, allows for precise control de impedancia, minimizing reflection and loss—a paramount concern for RF and high-speed digital applications.

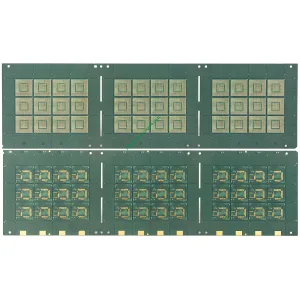

Types and Classification of Blind Via Structures

Blind via substrates can be categorized based on design architecture and application:

-

By Structure: Standard Blind Vias (connecting two adjacent layers) y Stacked Blind Vias (multiple vias aligned vertically across several layers, used for complex, deep interconnects).

-

By Location: Vías ciegas (from surface to inner layer) y Buried Vias (connecting inner layers only, not exposed on either surface). The combination of these types enables highly complex interconnect routing.

Key Advantages and Differentiating Features

| Característica | Benefit | Impacto |

|---|---|---|

| Eficiencia del espacio | Maximizes usable wiring area on inner layers. | Enables further miniaturization or increased functionality. |

| Enhanced Electrical Performance | Reduces signal stub effects and parasitics. | Improves signal integrity and speed for high-frequency chips. |

| Design Flexibility | Enables complex, high-density interlayer routing. | Facilitates advanced packaging like 2.5D/3D integration. |

| Improved Reliability | Reduces potential points for inner-layer short circuits. | Increases product longevity and field performance. |

Proceso de fabricación: A Journey of Precision

The production of a Blind Vias IC Substrate is a precise and multi-step process:

-

Diseño & Drilling File Generation: Using CAD tools (p.ej., Cadence, Mentor) following IPC-2581 pautas. Drill files specify via locations, sizes, and depths.

-

Preparación de material: Laminating copper foil onto the Mitsubishi HF core material.

-

Perforación láser: Using CO₂ or UV lasers to ablate the dielectric and form the micro-vias with precise depth control.

-

Desmearing & Metalización: Plasma desmearing cleans the via hole, followed by electroless copper deposition to make the hole walls conductive.

-

Pattern Plating & Imaging: Aplicando fotorresistente, exposición, developing, and electroplating to build up circuit traces and via barrels.

-

Laminación & Alineación de capas: Bonding multiple etched layers with preparar (B-stage) dielectric under heat and pressure. Registration accuracy es crítico (<±25 μm).

-

Final Processing: Applying solder mask (PSR-4000), acabado superficial (ACEPTAR), and electrical testing.

Primary Applications and Use Cases

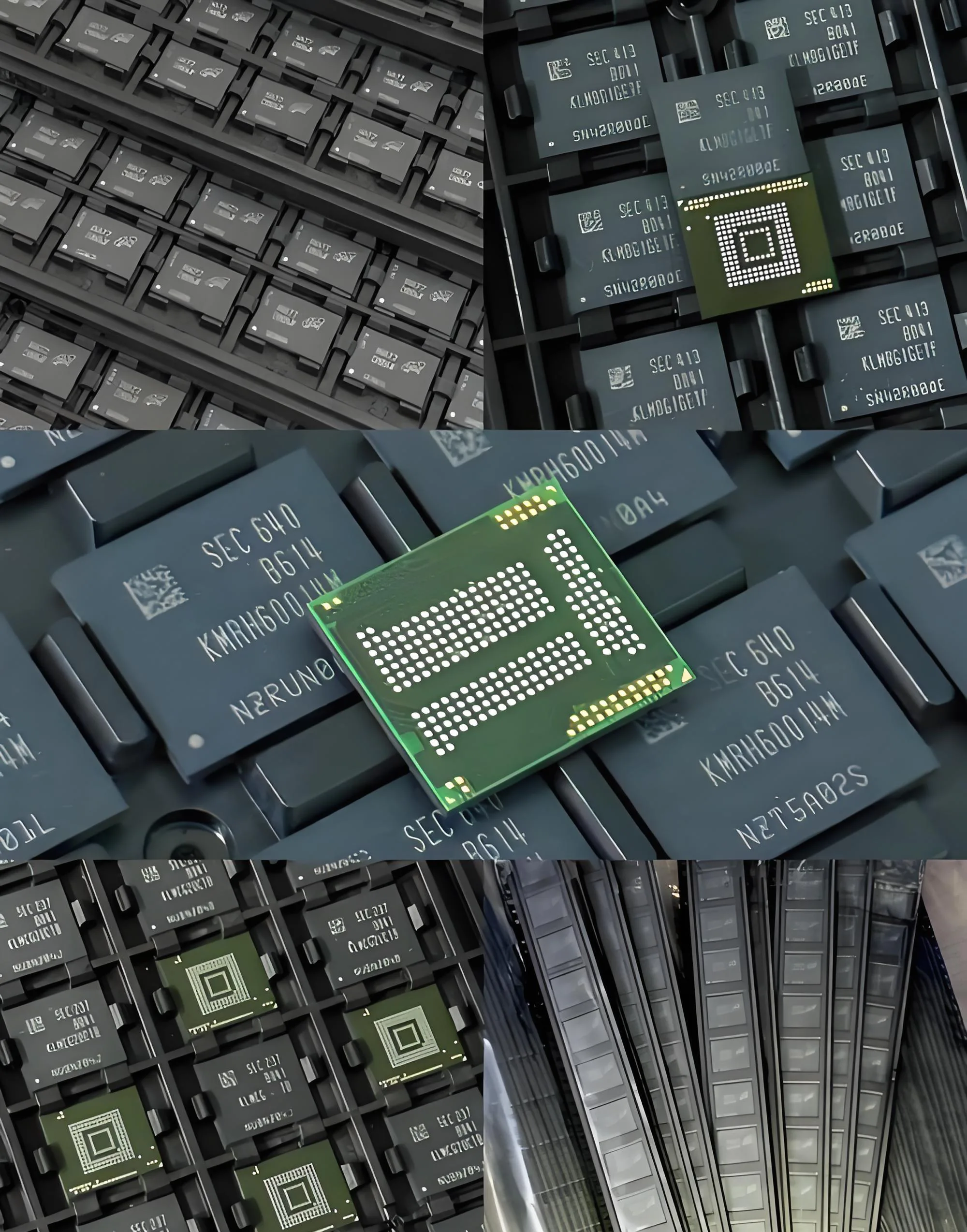

Blind Vias IC Substrates are essential in demanding applications:

-

Advanced Consumer Electronics: Teléfonos inteligentes, tabletas, and wearables utilize them for compact motherboard design, connecting application processors, memoria, and sensors.

-

Electrónica automotriz: Critical for ADAS radar modules, sistemas de infoentretenimiento, and engine control units (CUBRIR), where reliability under high temperature and vibration is key (aligned with IPC-6012DA for automotive).

-

Telecomunicaciones: 5G/6G base stations, network switches, y módulos de RF rely on them for excellent high-frequency signal integrity and impedance control.

-

Informática de alto rendimiento (HPC): Servidor, AI/ML accelerators, and GPUs use these substrates for dense, high-speed interconnects between silicon dies and memory.

Partner with UGPCB for your most challenging chip packaging projects. Our expertise in advanced materials like Mitsubishi HF and precision processes such as 30μm line technology and laser-drilled blind vias ensures your designs achieve optimal performance and reliability. Contact our engineering team today for a design review or prototype quote.

UGPCB LOGO

UGPCB LOGO