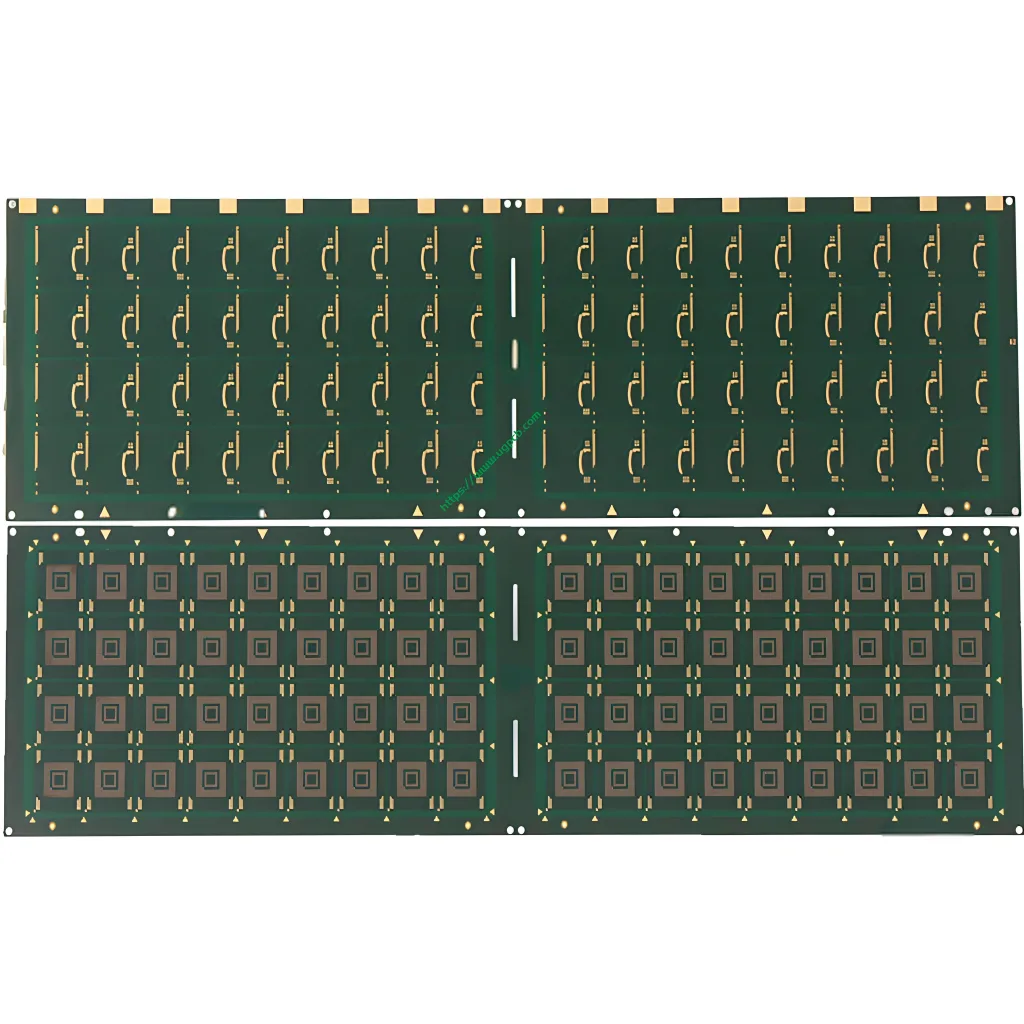

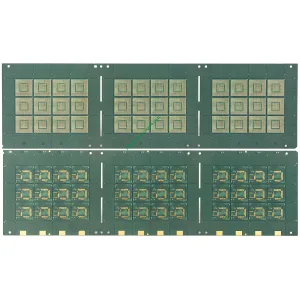

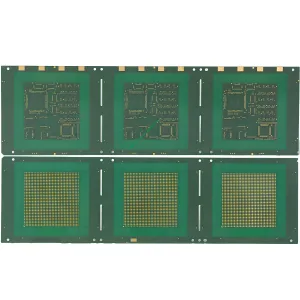

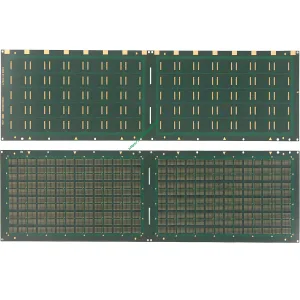

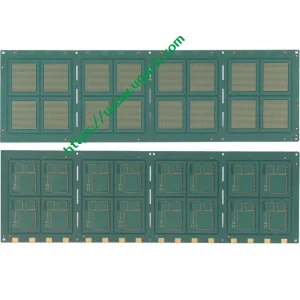

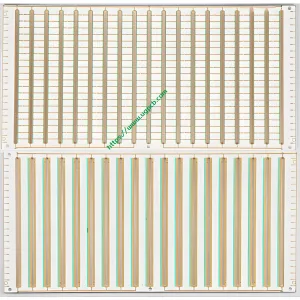

eMMC PCB Package Substrate Product Overview

In today’s data-centric world, the performance and reliability of embedded storage are critical. EMMC (embedded MultiMediaCard) serves as the core storage unit in smartphones, tabletas, IoT devices, and other consumer electronics. UGPCB, leveraging deep expertise in Interconexión de alta densidad (IDH) fabricación de PCB, offers specialized eMMC Package Substrate PCBs. Designed with HL832NS material in a 4-layer, ultra-thin configuration, this substrate is the essential platform for high-speed, stable electrical interconnection between the memory controller, NAND flash dies, y el tablero principal. It is the optimal solution for developing next-generation compact, high-capacity storage modules.

What is an eMMC Package Substrate PCB?

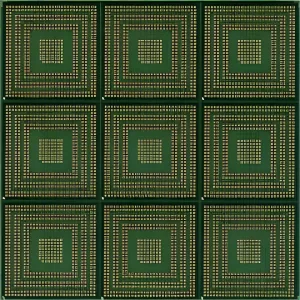

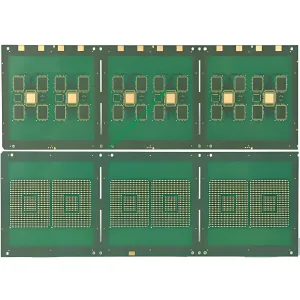

An eMMC Package Substrate PCB is a specialized, miniaturized placa de circuito impreso used internally within an eMMC chip package. It serves as the core interposer, providing the electrical connections and physical support between the storage controller silicon die, the NAND flash memory dies, and the external Ball Grid Array (BGA) interfaz. Its design and manufacturing quality directly determine the signal integrity, rendimiento térmico, and overall reliability of the final eMMC module.

Destacados de diseño & Especificaciones técnicas clave

To meet the stringent demands of eMMC chips for high bandwidth and miniaturization, UGPCB’s eMMC substrate focuses on these critical design parameters:

-

High-Density Routing: Supports ultra-fine circuitry with minimum line width/space of 20µm.

-

Micro-Via Capability: Características minimum via diameter of 0.1mm for high-density I/O fanout.

-

Stable Lamination: 4-layer construction with a controlled total thickness of 0.21mm, balancing electrical performance and mechanical strength.

-

High-Reliability Surface Finish: Oro suave (ACEPTAR) plating provides an oxidation-resistant, low-resistance surface for reliable wire bonding or flip-chip attachment.

-

Precise Solder Mask: PSR-4000 AUS308 solder mask offers excellent insulation and chemical resistance.

How It Works & Características estructurales

How It Works: The substrate acts as the internal “sistema nervioso” y “power grid” of the eMMC module. Its conductive traces and micro-vias route command signals from the controller to the NAND flash dies and return data. Dedicated power and ground planes ensure stable, low-noise power delivery.

Características estructurales:

-

Ultra-Thin & Compacto: 0.21mm final thickness y 11.5mm x 13mm unit size minimize space consumption.

-

Advanced Core Material: Built on HL832NS, a high-performance laminate known for excellent thermal stability and low signal loss (bajo Dk/Df), crucial for heat dissipation.

-

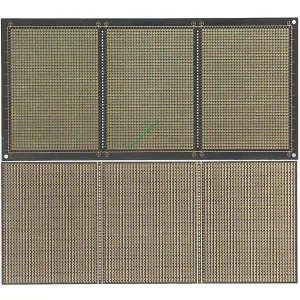

Multi-Layer Architecture: El 4-apilamiento de capas (typically signal, fuerza, suelo) optimizes signal paths, reduces crosstalk, and controls impedance.

-

BGA Pad Array: The bottom side features a precise BGA pad layout for reliable surface-mount technology (SMT) assembly of the entire module onto the host motherboard.

Primary Application & Casos de uso

Primary Application: Core interconnection platform within EMMC 5.1 and above chip packages.

Aplicaciones típicas (Casos de uso):

-

Teléfonos inteligentes & Tabletas: Primary internal storage.

-

Smart TVs & Set-Top Boxes: System storage and caching.

-

Dispositivos IoT: Smartwatches, smart home hubs requiring compact embedded storage.

-

Industrial Control Systems: Embedded devices demanding high data reliability.

-

Automotive Infotainment: Storage modules meeting automotive-grade stability requirements.

Clasificación & Composición de materiales

-

Clasificación: Can be categorized by application grade: Consumidor, Industrial, and Automotive (this model is tailored for consumer & high-end industrial applications).

-

Material Stack-Up:

-

Core Laminate: HL832NS Tg alta, Low-Loss material.

-

Conductive Layers: High-purity electrolytic copper foil.

-

Máscara de soldadura: PSR-4000 AUS308 (Verde, matte/gloss optional).

-

Acabado superficial: Oro de inmersión de níquel químico (ACEPTAR – Oro suave).

-

Performance Advantages & Características clave

-

Superior Signal Integrity: Controlled impedance and low-loss HL832NS material ensure stable high-speed data transfer.

-

Alta fiabilidad: Stringent process controls and material selection guarantee long-term durability.

-

Effective Thermal Management: The laminate’s good thermal conductivity aids in heat dissipation from the active dies.

-

Tight Manufacturing Tolerances: 20µm line/space and 0.1mm micro-vias demonstrate advanced PCB HDI fabricación expertise.

-

End-to-End Solution: UGPCB provides collaborative support from substrate design review y fabricación de PCB a rapid PCBA prototyping.

Production Process Overview

Our eMMC Package Substrate manufacturing follows a stringent HDI PCB process flow:

Material Prep → Inner Layer Imaging → Lamination → Laser Drilling (0.1mm vias) → Via Metallization → Outer Layer Imaging (20µm lines) → Solder Mask Application (PSR-4000) → Surface Finishing (Oro suave) → Electrical Testing → Routing/Scoring → Final Inspection & Embalaje.

Why Choose UGPCB for Your eMMC Package Substrate?

Choosing UGPCB means partnering with an expert in memory chip substrate manufacturing. We understand the technical evolution of storage interfaces and offer full-chain support to ensure your product excels in performance, costo, y confiabilidad.

Contact us today to discuss your eMMC Package Substrate requirements and request a quotation. Let UGPCB’s precision engineering be the reliable foundation for your next-generation storage solutions.

UGPCB LOGO

UGPCB LOGO