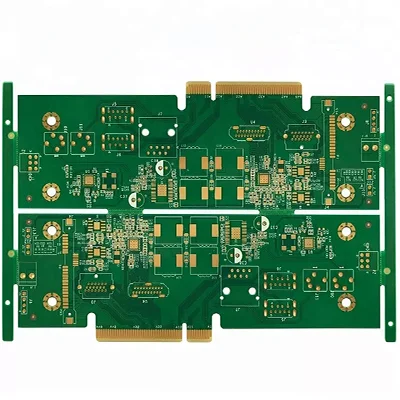

Overview of 6 Layer Golden Finger PCB

El 6 Layer Golden Finger PCB is a high-precision, multi-layered printed circuit board designed for advanced electronic applications. This product combines multiple layers of conductive traces and insulating materials to provide exceptional performance and reliability in various electronic devices.

Definición

A 6 Layer Golden Finger PCB is a type of multi-layer printed circuit board (tarjeta de circuito impreso) that features six individual layers of conductive material, separados por capas aislantes. El término “Golden Finger” refers to the specific surface treatment applied to the edges of the board, which involves immersion gold and additional gold plating on the contact fingers.

Requisitos de diseño

When designing a 6 Layer Golden Finger PCB, several key requirements must be considered:

- Calidad de material: High-quality FR4 material is essential for durability and performance.

- Configuración de capa: Six layers are needed to accommodate complex circuitry and signal routing.

- Espesor de cobre: A standard copper thickness of 1OZ ensures adequate conductivity.

- Tratamiento superficial: Immersion gold with additional gold finger plating enhances connectivity and corrosion resistance.

- Trace/dimensiones del espacio: A minimum trace/space of 4mil/4mil is required for precise circuit patterns.

- Procesos especiales: The gold finger process with a thickness of 0.1um is critical for reliable edge connections.

Principio de trabajo

El 6 Layer Golden Finger PCB operates based on the principles of electrical conductivity and insulation. Conductive traces on different layers create pathways for electrical signals, mientras que las capas aislantes evitan las interacciones no deseadas entre estas señales. The gold finger edges facilitate easy insertion into connectors, ensuring stable and reliable connections.

Aplicaciones

This type of PCB is widely used in applications that require high precision and reliability, como:

- High-speed digital circuits

- Equipos de telecomunicaciones

- Advanced computing systems

- Electrónica automotriz

- Dispositivos médicos

Clasificación

6 Layer Golden Finger PCBs can be classified based on their intended use, como:

- Signal Processing Boards: For handling high-frequency signals in communication devices.

- Power Distribution Boards: To manage power supply in complex electronic systems.

- Tablas de control: For controlling and managing various functions in electronic devices.

Materiales

Los materiales principales utilizados en la construcción de un 6 Layer Golden Finger PCB include:

- Materia prima: FR4, Un material de fibra de vidrio de retraso de llama conocido por sus excelentes propiedades dieléctricas y resistencia mecánica.

- Material conductor: Cobre, utilizado para las trazas conductivas.

- Tratamiento superficial: Immersion gold and additional gold plating for the gold fingers.

Actuación

The performance of a 6 Layer Golden Finger PCB is characterized by:

- Alta integridad de la señal: Debido a dimensiones precisas de traza/espacio y materiales de calidad.

- Conectividad confiable: Ensured by the gold finger surface treatment.

- Durabilidad: Enhanced by the robust FR4 base material and immersion gold finish.

- Eficiencia eléctrica: Pérdida de señal minimizada e interferencia debido a la configuración de capa optimizada.

Estructura

La estructura de un 6 Layer Golden Finger PCB consists of:

- Seis capas de material conductor: Alternando con capas aislantes.

- Gold Finger Edges: Plated with a thin layer of gold for enhanced connectivity.

- Protective Layers: Including solder mask and silkscreen for protection and identification.

Características

Key features of the 6 Layer Golden Finger PCB include:

- Tratamiento de superficie avanzado: Immersion gold plus gold finger for superior connection quality.

- Alta precisión: With a minimum trace/space of 4mil/4mil.

- Opciones de color personalizables: Disponible en verde o blanco.

- Grosor estándar: With a finished thickness of 1.6mm.

Proceso de producción

The production process for a 6 Layer Golden Finger PCB involves several steps:

- Preparación de material: Seleccionar y preparar hojas FR4 y papel de cobre.

- Apilamiento de capas: Capas alternas de cobre y materiales aislantes..

- Aguafuerte: Eliminar exceso de cobre para formar el patrón de circuito deseado.

- Enchapado: Applying immersion gold and additional gold finger plating.

- Laminación: Combinando las capas bajo calor y presión.

- Perforación: Creación de agujeros para componentes de agujeros y vías.

- Aplicación de máscara de soldadura: Protección del circuito de puentes de soldadura y factores ambientales.

- Impresión de plisabra: Agregar texto y símbolos para la colocación e identificación de los componentes.

- Control de calidad: Asegurar que el PCB cumpla con todas las especificaciones y estándares de diseño.

Use escenarios

El 6 Layer Golden Finger PCB is ideal for scenarios where:

- La alta integridad de la señal es crucial.

- Se requieren conexiones confiables y duraderas.

- Las limitaciones de espacio requieren un diseño compacto y eficiente.

- Se necesita tratamiento de superficie avanzado para un rendimiento mejorado.

UGPCB LOGO

UGPCB LOGO