-

UGPCB Sistema de tratamiento de gases de residuos de múltiples etapas: Pioneering a New Era of Green Production in the PCB Industry with Innovative Technology

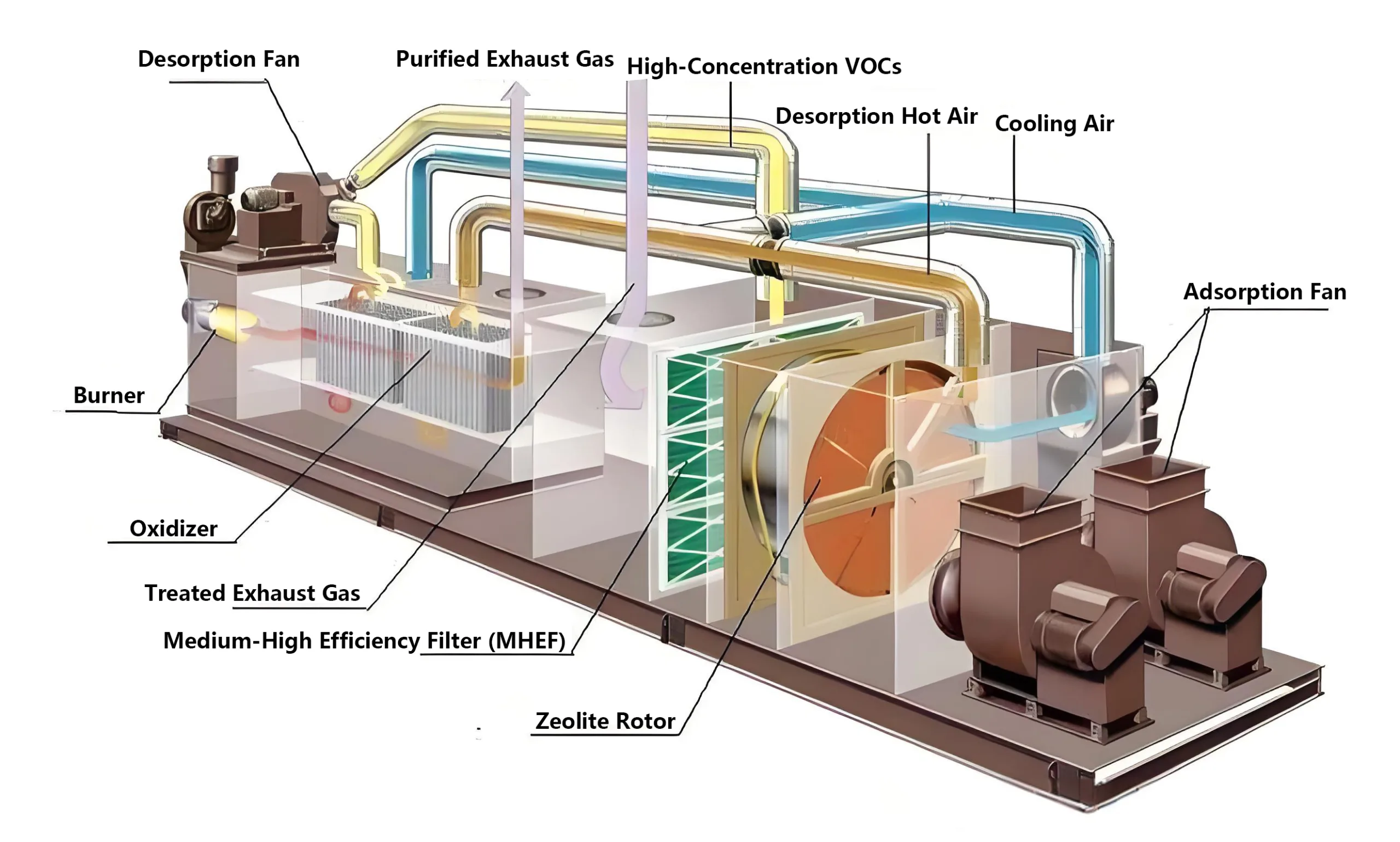

In the field of tarjeta de circuito impreso fabricación, balancing environmental protection and efficiency has always been a core challenge. As a socially responsible and innovative industry pioneer, UGPCB has introduced a multi-stage waste gas treatment system that deeply integrates cutting-edge technologies such as activated carbon adsorption and catalytic combustion. This system provides a comprehensive environmental solution covering the entire PCB production process. Not only does it meet the stringent requirements of the “PCB Circuit Board Waste Gas Emission Standards” – with non-methane hydrocarbons ≤15mg/m³ and hydrochloric acid mist ≤8mg/m³ – but it also achieves a VOCs removal rate of 98.7%, setting a benchmark for green production in the PCB industry.

Technical Analysis: An Environmental Closed Loop from Physical Isolation to Chemical Conversion

The core of this system adopts a “classified collection + graded treatment” process route:

-

Acidic Waste Gas Treatment: A three-stage spray tower system uses circulating alkali liquor for neutralization. The first stage, con un 5% NaOH solution, removes 90% of acidic gases. The second stage, con un 3% NaOH solution, performs deep purification. The third stage, a water wash, ensures mist droplet residues remain below 0.5mg/m³.

-

Organic Waste Gas Treatment: Activated carbon adsorption achieves an efficiency of 83.3% (calculated by the formula η=(C₀-C)/C₀×100%, with an initial concentration of 60mg/m³ reduced to 10mg/m³ after treatment). The concentrated gases are then completely decomposed through RTO (Regenerative Thermal Oxidizer) combustion (temperature ≥760℃, residence time ≥1.2 seconds).

-

Catalytic Combustion Technology: Using a platinum-palladium catalyst, VOCs are oxidized into CO₂ and H₂O at 300-450℃. The heat recovery efficiency is ≥95%, resulting in over 40% energy savings compared to traditional thermal combustion.

Environmental Technology Advantages of UGPCB

Adaptable Modular Design for Capacity Expansion

The equipment uses standardized modular components that can be flexibly combined according to production needs. By adding a molecular sieve rotor concentration + CO catalytic oxidation system, nuestro fábrica de PCB increased the formaldehyde removal rate to 99.2%, while also achieving a recovery benefit of 1.2 tons/month for isopropanol vapor.

Intelligent Control System Ensures Stable Operation

Equipped with a PLC automatic monitoring system, it adjusts parameters in real-time, such as the pH value of the spray tower and the temperature of the RTO combustion chamber. Through upgrading to a two-stage counter-current spray tower and adding polymer absorbents, our company has stabilized hydrochloric acid mist emissions below 5mg/m³, far below the industry average.

Industry Application and Environmental Benefits

After implementing renovations in our Tablero de HDI production workshop:

• VOCs Reduction: Annual reduction reached 120 tons, equivalent to the carbon sequestration capacity of 6,000 mature trees.

• Energy Consumption Optimization: The RTO system’s heat recovery efficiency increased to 92%, equivalent to annual natural gas cost savings of over 800,000 RMB.

• Compliance Assurance: The treatment efficiency for cyanide-containing waste gas improved from 60% a 99.9%, fully meeting the “Electroplating Pollutant Discharge Standard” (GB21900-2008).Social Responsibility and Industry Leadership

UGPCB regards environmental protection not just as a compliance requirement but as part of its corporate DNA. Through the upgrading of our environmental facilities, we have created both economic benefits and social value, setting a benchmark and example for other enterprises in the PCB industry.

The company’s environmental philosophy is clear: we strive for both economic prosperity and a clear environment, valuing green mountains and clear waters as much as material wealth.

-

UGPCB Sistema de tratamiento de gases de residuos de múltiples etapas

Anterior: Laboratorio Químico

UGPCB LOGO

UGPCB LOGO