Sistema de tratamiento de efluentes de UGPCB: Setting New Benchmarks for Green Manufacturing in the PCB Industry

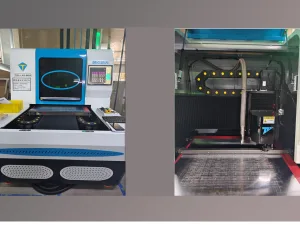

Equipment Overview and Core Technology Analysis

UGPCB employs a modular intelligent wastewater treatment system, specifically designed to address the high heavy metal and organic pollution characteristics of the tarjeta de circuito impreso industria. This system integrates three core technological modules: chemical precipitation, membrane separation, and IoT monitoring. It achieves the following:

-

Heavy metal removal rate ≥ 99.8% (compliant with GB21900-2020 Table 3 estándares)

-

CODcr treatment efficiency of 92% (exceeding the “Electronic Industry Pollutant Discharge Standards”)

-

100% tasa de recuperación de cobre (achieved through electrodeposition technology for resource recycling)

The system utilizes an IoT-based intelligent control system to monitor over 20 parameters in real time, including pH levels, heavy metal concentration, and flow rate. Data is uploaded to a cloud platform, habilitador:

-

Remote fault diagnosis (response time ≤ 15 minutos)

-

Intelligent optimization of chemical dosing (reducing chemical usage by over 30%)

-

Dynamic energy consumption adjustment (power consumption ≤ 3.5 kWh per ton of water treated)

Environmental Technology Advantages of UGPCB

Closed-Loop Resource Recycling System

-

Wastewater reuse rate of 85%: Achieved through a combination of reverse osmosis (RO) and ultrafiltration (UF) procesos, with treated water quality meeting GB/T 19923-2005 standards for industrial water reuse.

-

Metal resource recovery: Annual recovery of 1,200 tons of copper, tin, and other metals, generating economic benefits of 24 million RMB (based on 2025 market prices).

IoT-Enabled Intelligent Operation and Maintenance

-

Equipment health prediction: Utilizes vibration sensors and AI algorithms to provide early warnings of potential failures up to 72 hours in advance.

-

Carbon emission management: Integrated carbon footprint calculation module displays real-time carbon emission data during the treatment process.

Certifications and Standard Leadership

-

ISO 14001 Environmental Management System Certification

-

UL Certification (ECOLOGO® Environmental Label Certification)

-

Cumplimiento de ROHS (meets EU Restrictions on Hazardous Substances Directive)

Environmental Practices in PCBA Production

En el tarjeta de circuito impreso (Conjunto de placa de circuito impreso) phase, UGPCB has established a lead-free production system:

-

Use of lead-free solder: Employs Sn-Ag-Cu alloy with lead content < 0.1%

-

Exhaust gas treatment system: Combines activated carbon adsorption and catalytic combustion technologies to maintain VOC emissions below 10mg/m³

-

Electrostatic precipitators: Achieve particulate matter capture efficiency ≥ 99.9%

Industry Impact and Social Responsibility

Driving Industry Standard Upgrades

-

Participation in drafting the “China Electronics Circuit Industry Association Environmental Technology Standards”

-

Involvement in establishing energy consumption standards for PCB wastewater treatment (≤ 4.0 kWh per ton of water)

Green Supply Chain Development

Implementation of a traceability platform for PCB waste materials, enabling full-process tracking from raw materials to recycling.

Environmental Benefits Data

-

Annual reduction in emissions: COD 180 tons, ammonia nitrogen 25 tons, heavy metals 3.2 tons

-

Water conservation benefits: Annual reduction of 400,000 cubic meters in freshwater consumption

Future Technology Outlook

UGPCB is currently developing bio-electrochemical coupled treatment technology, with the following anticipated outcomes:

-

40% reduction in treatment costs (target achievement by 2026)

-

Achievement of microelectronic-grade pure water reuse (resistivity ≥ 18 MΩ·cm)

UGPCB LOGO

UGPCB LOGO