Introdução

Flexible Printed Circuit Boards (FPCs) have become indispensable in foldable smartphones, dispositivos vestíveis, and aerospace electronics due to their ultra-thin profile and bendable nature. No entanto, their design complexity surpasses traditional rigid PCB, requiring multidisciplinary expertise in materials science, mechanical simulation, and process innovation. This comprehensive guide explores critical aspects of flexible Projeto de PCB through industry-proven methodologies and cutting-edge technologies.

1. Ciência dos Materiais: Foundation of Flexible PCBs

1.1 Substrate Selection: Balancing Performance and Cost

Flexible substrates must simultaneously achieve thermal stability (>260°C for PI vs <120°C for PET), bending endurance, and dielectric properties. Poliimida (PI) dominates high-end applications with its low CTE (≈12 ppm/℃), while polyester (PET) serves cost-sensitive static applications. Emerging low-modulus PI substrates (<3 GPa) enable million-cycle dynamic bending durability.

Technical Formula:

Bending stress calculation:

σ = (E·t)/(2R)

Where E=elastic modulus, t=thickness, R=bend radius. Reducing E or increasing R decreases stress concentration by 62%.

1.2 Copper Foil and Coverlay: Mechanical Harmony

Rolled-annealed (RA) copper foil improves ductility by 30% over electrodeposited (DE) foil in dynamic bending zones. Optimal coverlay combines acrylic adhesive (15-25μm) with PI film for balanced adhesion and flexibility.

1.3 Protective Layer Innovations

Mesh ground planes and arc-shaped copper reinforcements (≥0.2mm width) reduce tearing risks by 70% in vulnerable areas like gold fingers. ENIG or OSP+selective gold plating ensures reliable soldering.

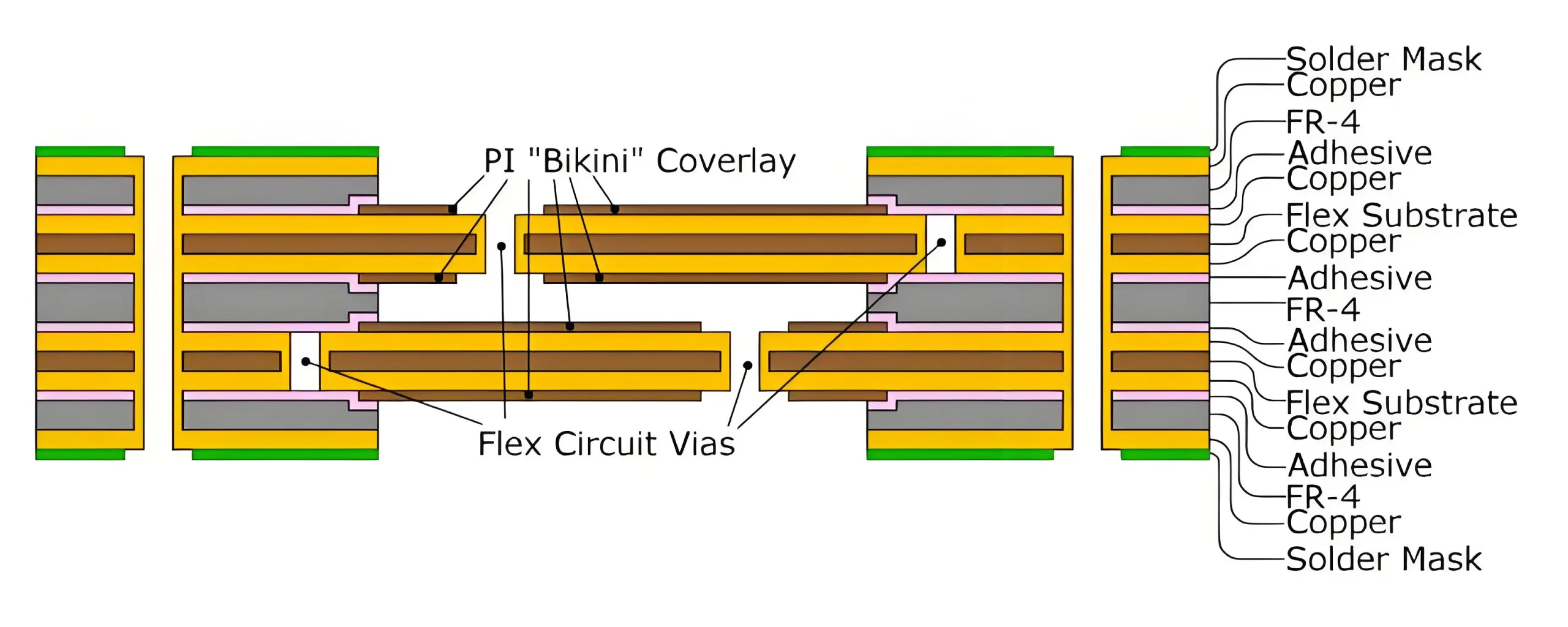

2. Stackup Architecture: Engineering Rigid-Flex Synergy

2.1 Layer Standardization and Signal Integrity

-

Camadas de sinal: Central positioning minimizes EMI

-

Power planes: Solid copper (<50mΩ target impedance)

-

Ground layers: Grid patterns (≤5mm spacing) reduce loop areas

Estudo de caso: 8-layer rigid-flex PCB with 2R+4F+2R configuration achieves 100,000+ Ciclos de dobra.

2.2 Zonas de transição rigides-flex

Implement 1mm+ buffer zones with perpendicular routing and arc corners (radius≥3×trace width) to distribute stress.

3. Dynamic Bending Optimization

3.1 Bend Radius Golden Rules

Minimum bend radius requirements:

-

Static: R<sub>min</sub> ≥5t

-

Dynamic: R<sub>min</sub> ≥10t

(por exemplo, 0.2mm PI requires ≥2mm dynamic radius)

3.2 Simulation-Driven Validation

Finite Element Analysis (FEA) identifies high-strain areas. Serpentine routing in foldable phones improves fatigue life to 200,000+ ciclos.

4. Routing Principles: Electrical-Mechanical Balance

4.1 Bending Zone Prohibitions

-

No vias/components within 5mm of bend lines

-

Staggered adjacent-layer traces prevent “I-beam” stress

4.2 Controle de impedância

Characteristic impedance formula for high-speed signals:

Z₀ = [87/√(e<sub>r</sub>+1.41)] × ln[5.98h/(0.8w+t)]

Entre eles, er is the dielectric constant, h is the dielectric thickness, w is the line width, and t is the copper thickness.

Differential serpentine routing (2×spacing) minimizes crosstalk.

5. Manufacturing Collaboration

5.1 IPC-2581 Standard Implementation

Unified XML format reduces communication errors by 80%, boosting first-pass yield from 65% para 92% in drone antenna projects.

5.2 DFM Guidelines

-

Trace spacing: ≥4mil

-

Perfuração a laser: ≥4mil holes (±1mil accuracy)

-

Coverlay openings: 0.1mm larger than pads

6. Fronteiras Futuras

6.1 3D Stretchable Circuits

UESTC’s 3D-LSC process enables meter-scale flex circuits with 5-layer stacking, applied in medical wearables.

6.2 Nanomaterial Breakthroughs

Graphene/PU composites achieve 10<sup>-6</sup> Ω·cm resistivity with <5% performance degradation after 100k bends.

Conclusão

Flexible PCB design demands cross-disciplinary innovation in materials, mechanics, and electronics. By implementing these strategies and adopting emerging standards like IPC-2581, engineers can develop next-generation flex circuits with enhanced reliability and density for advanced applications.

LOGOTIPO UGPCB

LOGOTIPO UGPCB