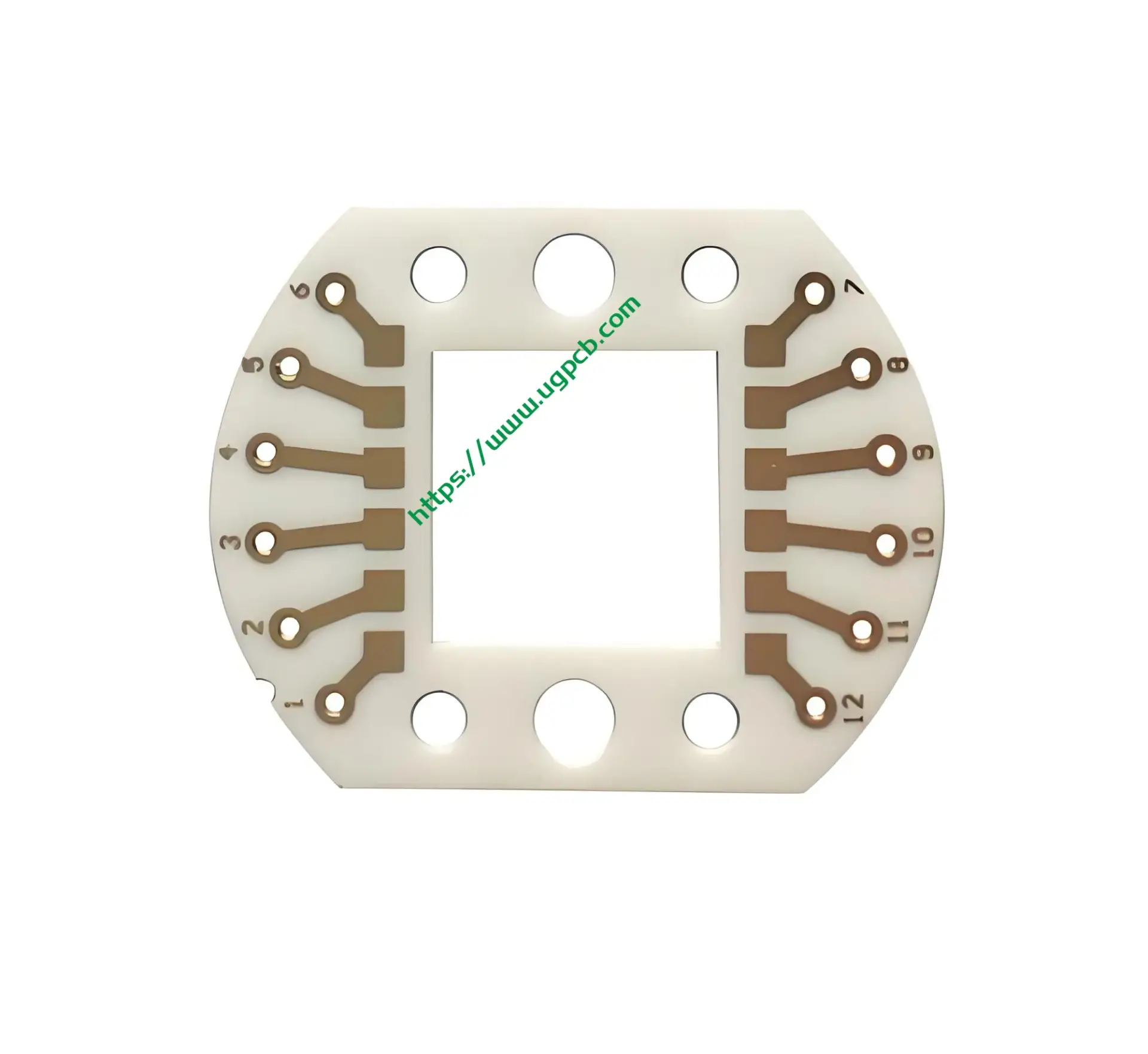

Visão geral

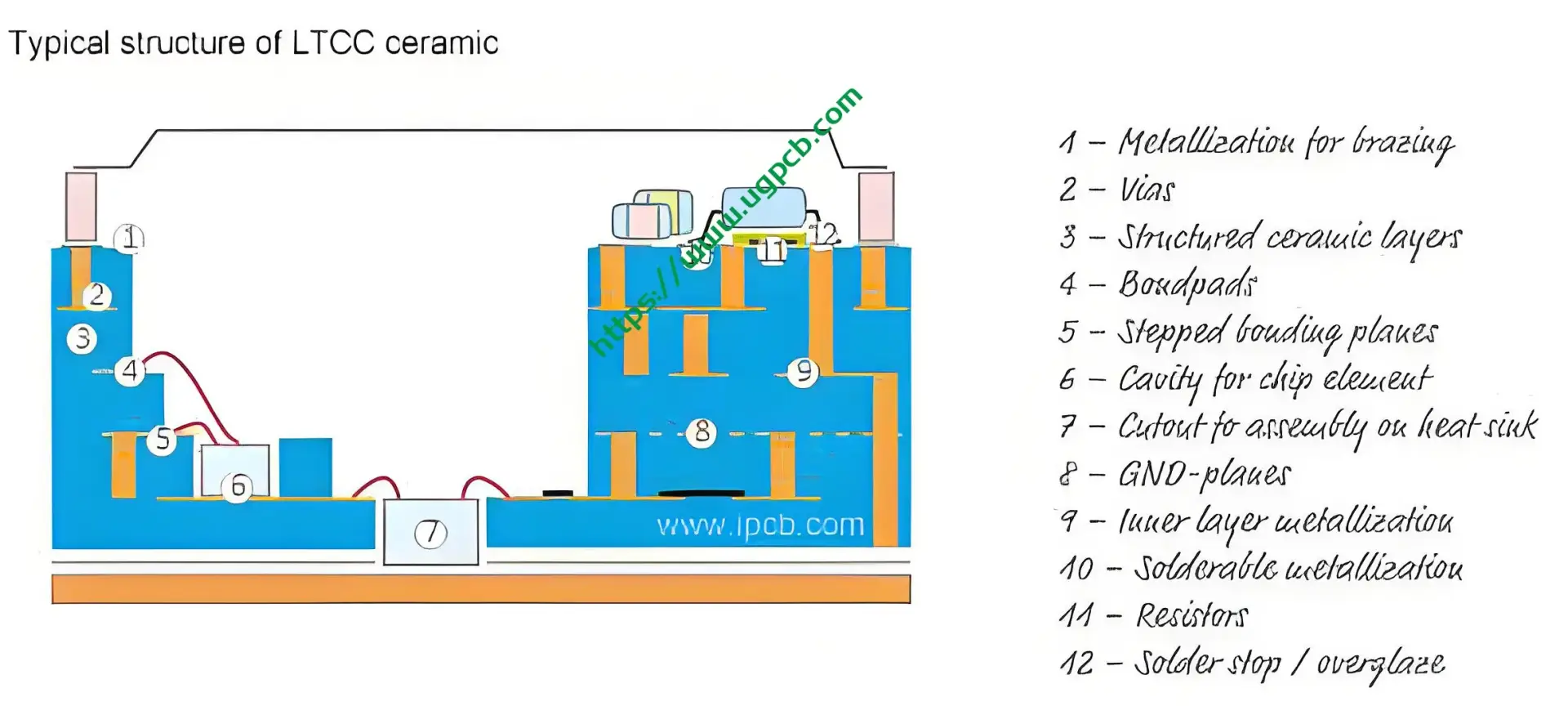

LTCC PCB stands for Low Temperature Co-fired Ceramic Placa de circuito impresso, um tipo especializado de PCB known for its advanced material composition and exceptional performance in various electronic applications. This technology combines ceramic substrates with metallic conductors, fired at relatively low temperatures to create a robust and versatile placa de circuito.

Composição de materiais

LTCC PCBs are primarily made of ceramic powders mixed with glass frits and organic binders. The ceramic substrate provides excellent thermal stability, while the metallic conductors (usually silver, cobre, or gold) offer high conductivity. The material selection allows for fine feature resolution and precision in manufacturing.

Características de desempenho

LTCC PCBs exhibit several notable performance characteristics:

High thermal conductivity and low thermal expansion coefficient, ensuring stable operation over a wide temperature range.

Excellent electrical insulation properties due to the ceramic substrate.

High reliability and durability, suitable for harsh environments.

Fine line resolution and tight tolerance capabilities, enabling complex circuit designs.

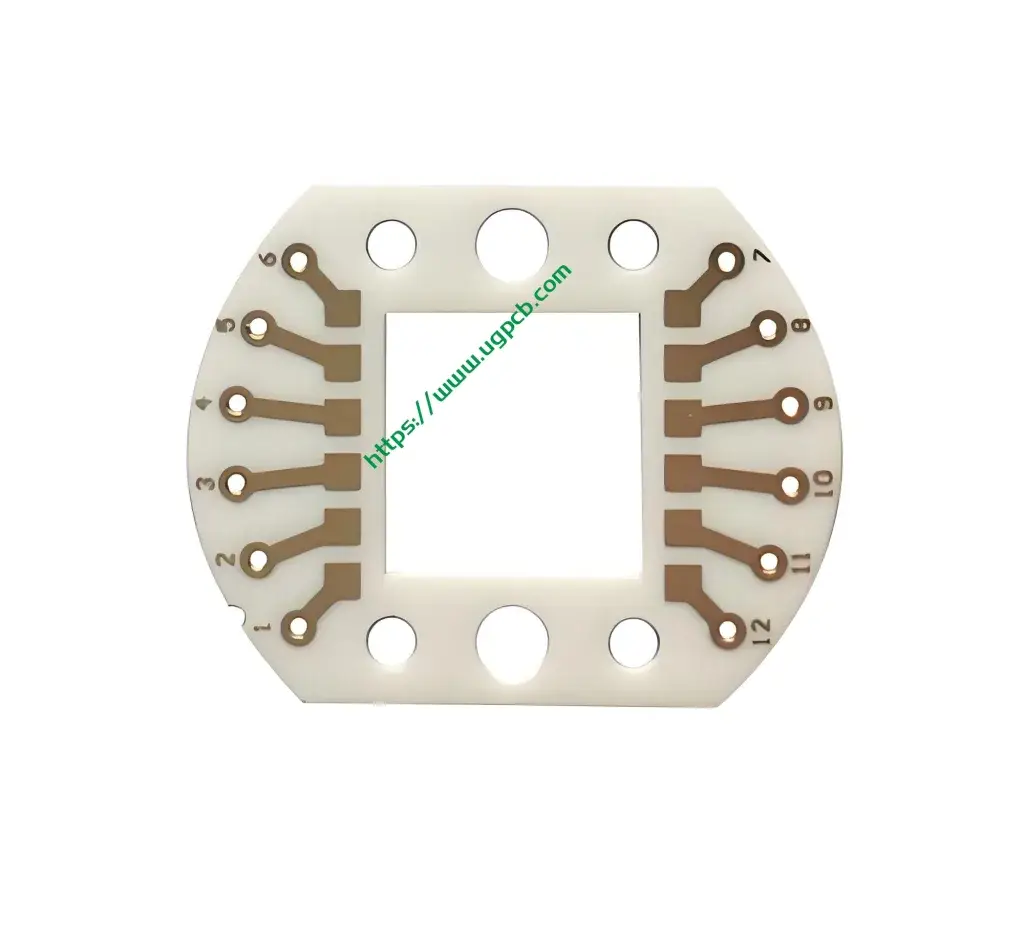

Key Features

Here are some key features of LTCC PCBs:

- Maximum shape size of 100 mm × 100 milímetros, accommodating a wide range of designs.

- Minimum line width and spacing of 0.075 mm and 0.15 milímetros, respectivamente, allowing for dense circuit layouts.

- Printed conductor thickness ranging from 10 para 25 micrometers, offering precise control over conductor dimensions.

- Printing line width accuracy of ±10 micrometers, ensuring consistent and reliable circuit performance.

- Stack alignment accuracy of ≤30 micrometers, maintaining precise layer alignment during manufacturing.

- Minimum through-hole diameter of 0.1 milímetros, enabling efficient component interconnection.

- Sintering shrinkage accuracy of ±0.2%, ensuring dimensional stability after firing.

- Minimum distance between conductor and shape edge of 0.2 milímetros, and between metal through-hole and line of 0.15 milímetros, preventing electrical shorts and ensuring circuit integrity.

- Minimum overlap distance of resistance/conductor of 0.15 milímetros, maintaining proper circuit functionality.

- Minimum resistance size of 0.15 mm × 0.15 milímetros, enabling precise resistor placement and value control.

Processo de Produção

The production of LTCC PCBs involves several key steps:

Tape casting: Ceramic slurry is cast into thin sheets to form the substrate layers.

Perfuração a laser: Precision laser drilling creates vias for interconnection.

Screen printing: Conductive inks are printed onto the ceramic substrate to form circuits and components.

Stacking and lamination: The layers are precisely aligned and laminated together.

Sintering: The assembled PCB is fired at low temperatures to sinter the ceramic and metallic components together, forming a solid and durable circuit board.

Inspection and testing: Final inspections and electrical tests ensure the quality and performance of the LTCC PCB.

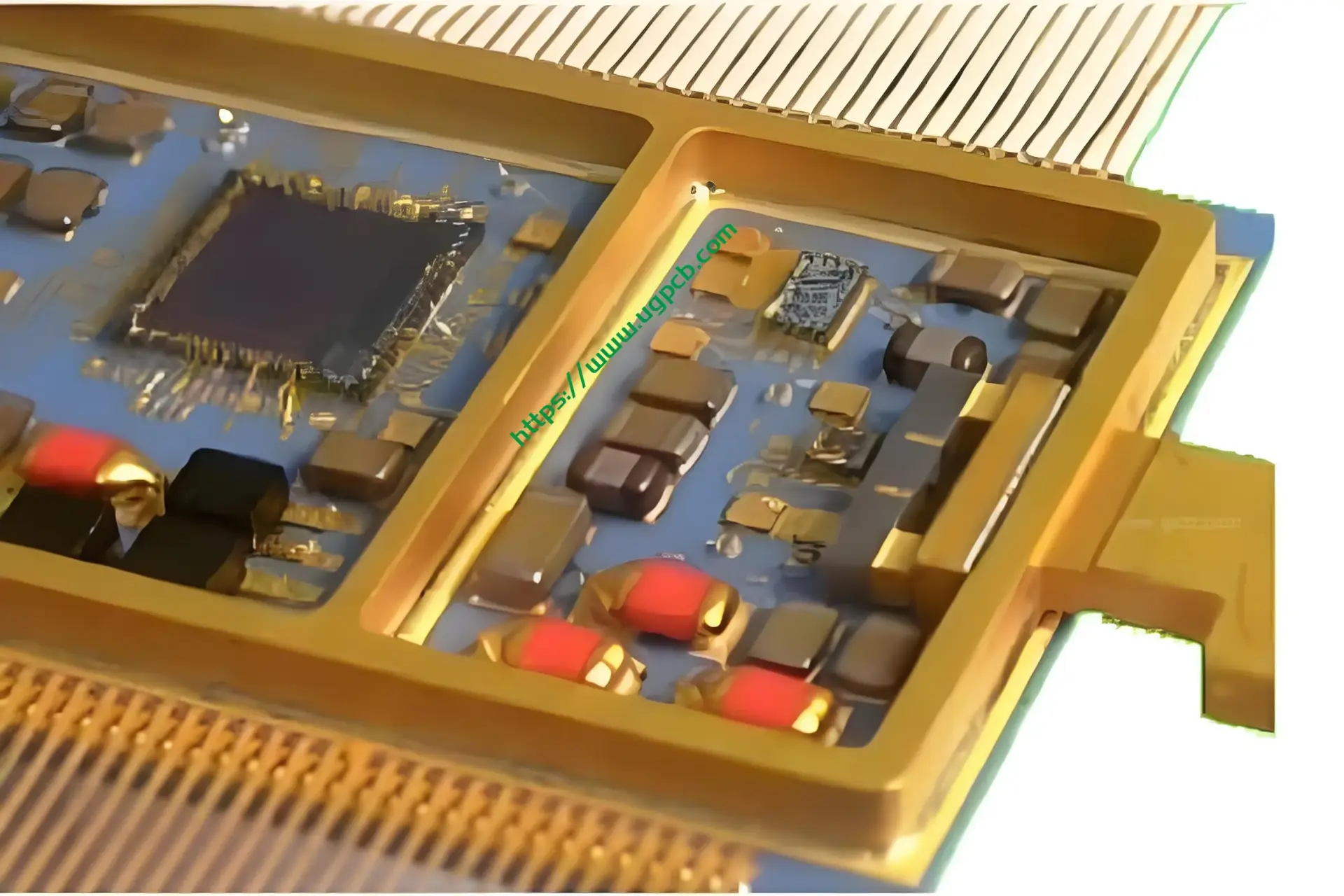

Cenários de aplicação

LTCC PCBs are ideal for various high-performance applications, incluindo:

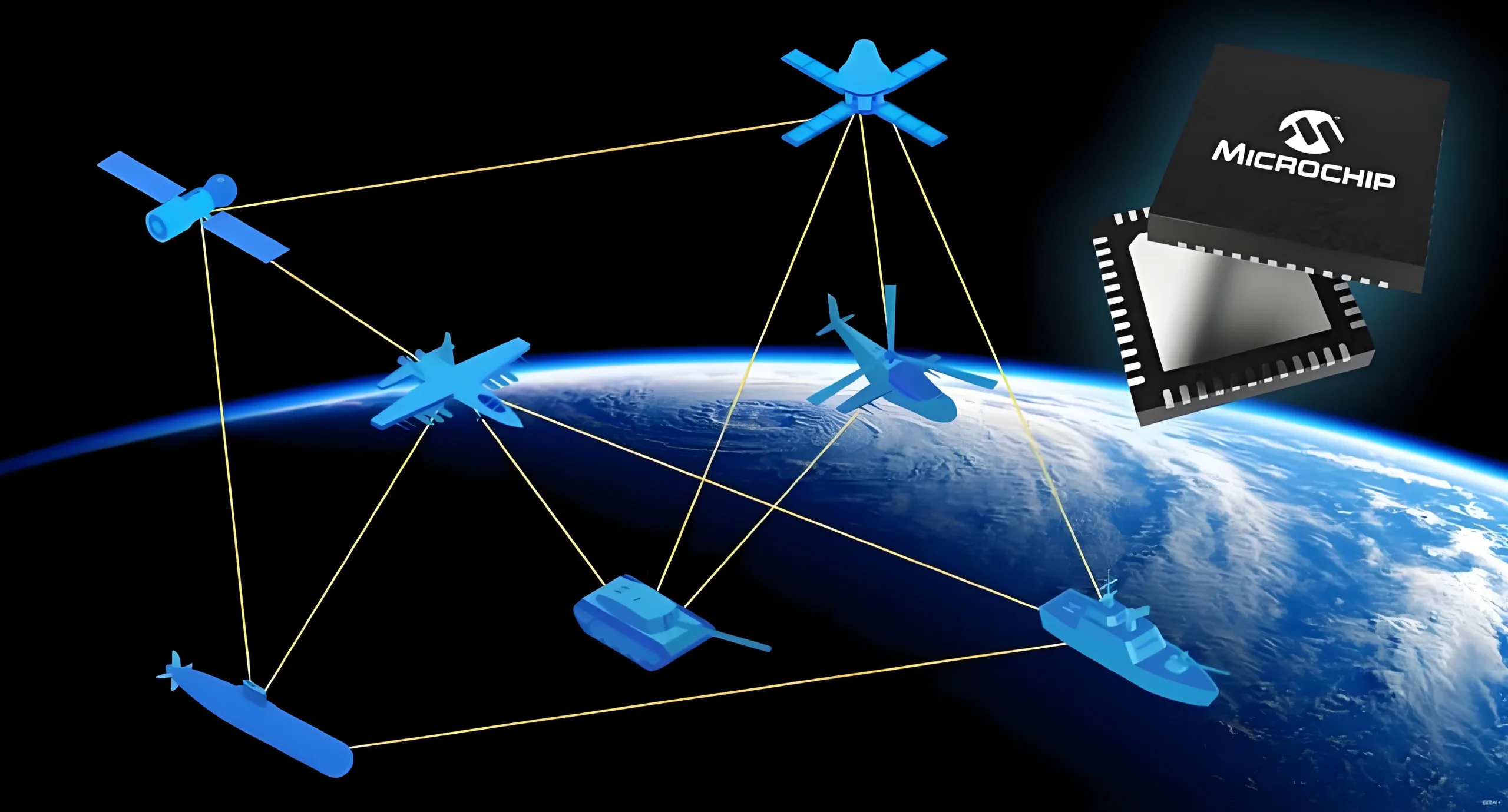

High-frequency microwave circuits: Leveraging their low loss and high-frequency characteristics.

Eletrônica automotiva: Providing reliable performance in harsh environments.

Aerospace and defense systems: Offering high-temperature stability and ruggedness.

Medical electronics: Ensuring durability and reliability in critical healthcare devices.

Telecomunicações: Supporting high-speed signal transmission and compact designs.

Conclusão

LTCC PCBs offer a unique combination of material properties, fabricação de precisão, and versatile application capabilities. Their advanced features make them an excellent choice for demanding electronic systems requiring high performance, confiabilidade, and stability.

LOGOTIPO UGPCB

LOGOTIPO UGPCB