ในยุคที่ปัญญาประดิษฐ์มาบรรจบกับหุ่นยนต์, มีความซับซ้อน พีซีบี ทำหน้าที่เป็น “ระบบประสาท” ของเครื่องจักรฮิวแมนนอยด์, ทำให้สามารถประสานการรับรู้ได้อย่างราบรื่น, คิด, และการกระทำ. หุ่นยนต์ฮิวแมนนอยด์กำลังเปลี่ยนจากนิยายวิทยาศาสตร์สู่ความเป็นจริง, การเปลี่ยนแปลงที่ได้รับการสนับสนุนขั้นพื้นฐานโดยขั้นสูง แผงวงจรพิมพ์ (พีซีบี) เทคโนโลยี. ทำหน้าที่เป็นหุ่นยนต์ “เครือข่ายประสาท,” PCB ช่วยให้การสื่อสารระหว่างเซ็นเซอร์มีประสิทธิภาพ, แอคชูเอเตอร์, และโปรเซสเซอร์ AI, เป็นรากฐานที่สำคัญสำหรับการสร้างระบบหุ่นยนต์ขั้นสูง.

ด้วยความก้าวหน้าอย่างรวดเร็วของ AI, 5ช, และเทคโนโลยี IoT, ความต้องการ PCB สำหรับหุ่นยนต์ฮิวแมนนอยด์มีเพิ่มมากขึ้น. ความหนาแน่นสูง, ความยืดหยุ่น, และการจัดการระบายความร้อนที่มีประสิทธิภาพได้กลายเป็นข้อกำหนดหลัก, ขับรถ อุตสาหกรรมพีซีบี เข้าสู่วงจรใหม่ของนวัตกรรม.

01 การเพิ่มขึ้นของหุ่นยนต์ฮิวแมนนอยด์: โอกาสการเติบโตใหม่สำหรับตลาด PCB

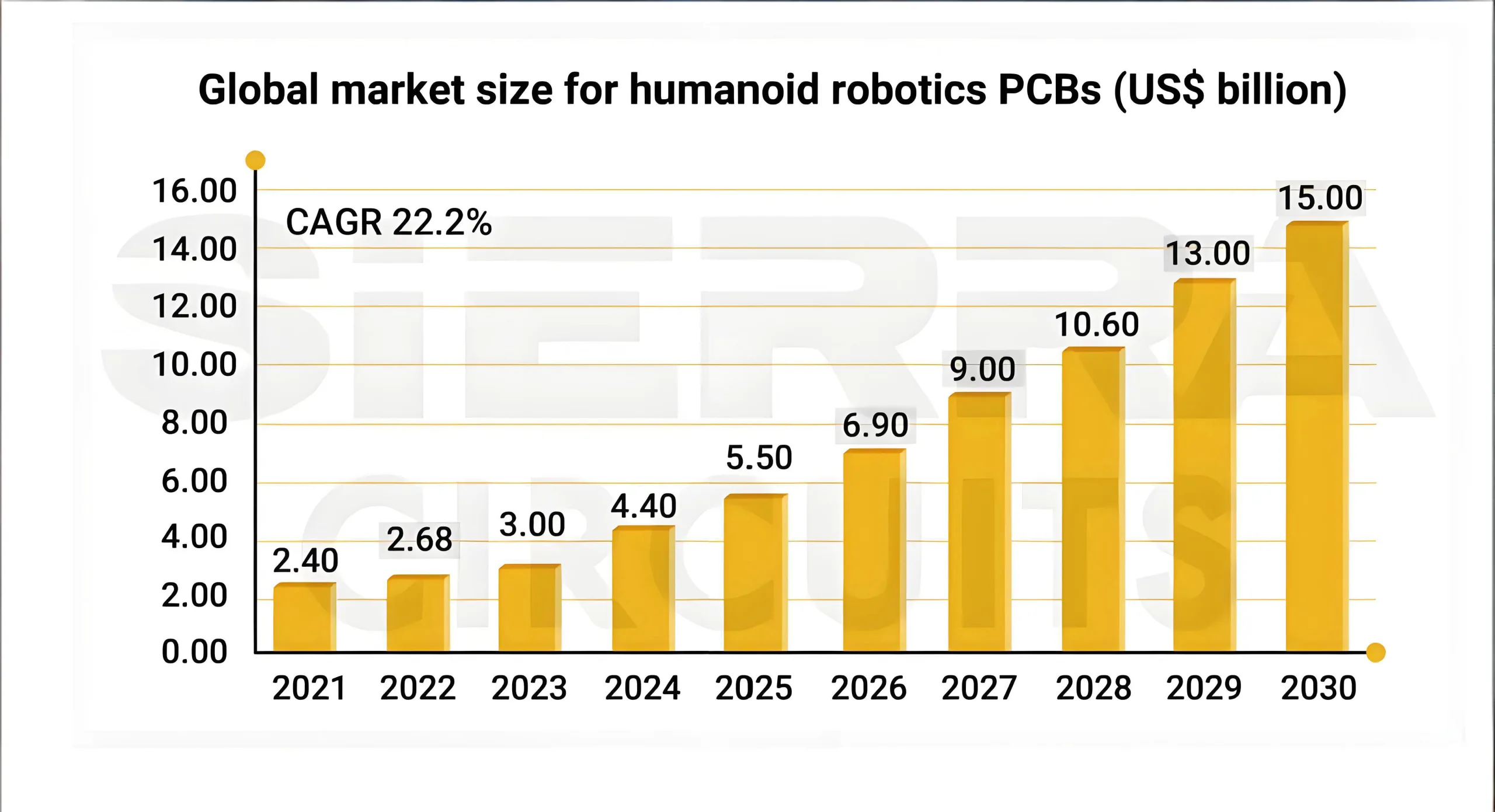

ท่ามกลางการเติบโตที่ทำงานร่วมกันในการลงทุนด้านคอมพิวเตอร์ AI และนวัตกรรมอุปกรณ์ปลายทาง, ตลาด PCB หุ่นยนต์ฮิวแมนนอยด์กำลังประสบกับการเติบโตอย่างรวดเร็ว. ตามข้อมูลการวิจัยของ iMedia, ตลาด PCB ของจีนถึงแล้ว 415.6 พันล้านหยวนใน 2024, เพิ่มขึ้นปีต่อปีของ 8.3%. การเติบโตนี้ส่วนใหญ่ได้รับแรงผลักดันจากภาคส่วนเกิดใหม่ เช่น เซิร์ฟเวอร์ AI และยานพาหนะพลังงานใหม่.

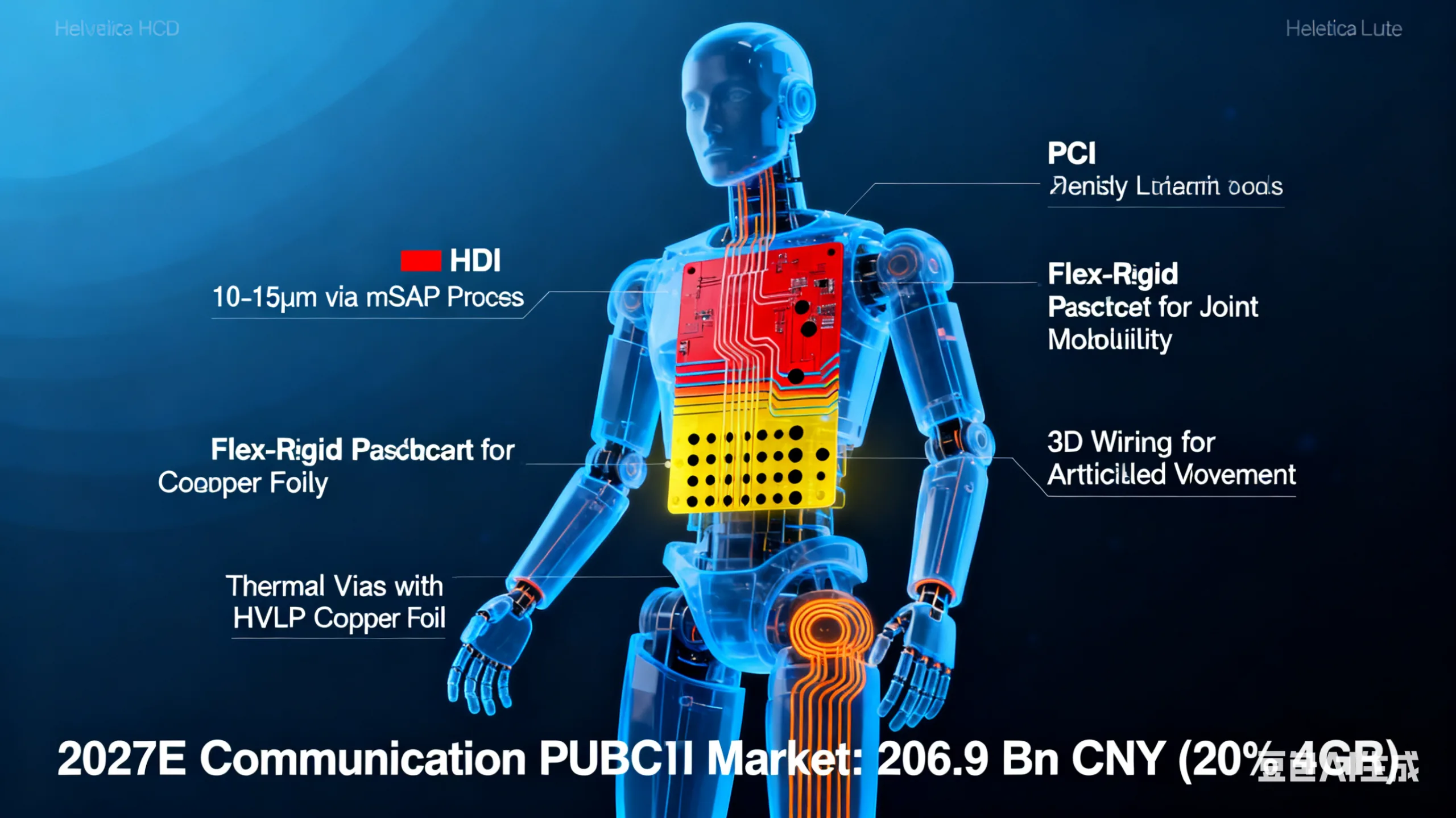

เป็นการบูรณาการเทคโนโลยีล้ำสมัยที่หลากหลาย, หุ่นยนต์ฮิวแมนนอยด์นำเสนอความต้องการที่หลากหลายและซับซ้อนมากขึ้น พีซีบี (ชุดประกอบแผงวงจรพิมพ์). หุ่นยนต์ตัวเดียวอาจมี PCB หลายสิบชิ้นพร้อมฟังก์ชันที่หลากหลาย, มีตั้งแต่ขั้นพื้นฐาน บอร์ดแข็ง สู่การเชื่อมต่อระหว่างกันที่มีความหนาแน่นสูง (HDI) บอร์ด, วงจรพิมพ์ที่ยืดหยุ่น (FPC), และ บอร์ดแบบแข็ง. PCB เหล่านี้รวมกันเป็นหุ่นยนต์ “ระบบประสาท”

รายงานการวิจัยของ Guosen Securities ระบุว่า AI จะเป็นตัวขับเคลื่อนการเติบโตที่โดดเด่นสำหรับอุตสาหกรรม PCB ในอนาคต 3-5 ปี. พวกเขาคาดการณ์ว่าตลาด PCB การสื่อสารแบบมีสายจะเข้าถึงได้ 206.9 พันล้านหยวนโดย 2027, ด้วยอัตราการเติบโตต่อปีแบบทบต้นสองปี (cagr) ของ 20%. แนวโน้มการเติบโตนี้จะส่งผลดีโดยตรงต่อภาค PCB หุ่นยนต์ฮิวแมนนอยด์.

02 ความท้าทายทางเทคนิค: ปรับสมดุลการเชื่อมต่อระหว่างกันความหนาแน่นสูงและการจัดการระบายความร้อน

หุ่นยนต์ฮิวแมนนอยด์ การออกแบบ PCB เผชิญกับอุปสรรคทางเทคนิคมากมาย. สิ่งสำคัญที่สุดคือความต้องการ การเชื่อมต่อระหว่างกันที่มีความหนาแน่นสูง (HDI). การส่งสัญญาณจำนวนมากภายในพื้นที่จำกัดต้องใช้ PCB ที่มีความสามารถในการส่งสัญญาณแบบเส้นละเอียดพิเศษ. มาเธอร์บอร์ดเซิร์ฟเวอร์ AI ขั้นสูงในปัจจุบันต้องการความกว้างของเส้น/ระยะห่าง 10-15μm อยู่แล้ว, ทำได้โดยผ่านกระบวนการกึ่งเติมแต่งที่ได้รับการดัดแปลง (mSAP). เทคโนโลยีที่คล้ายกันจะค่อยๆ ถูกนำไปใช้กับการออกแบบบอร์ดควบคุมหลักสำหรับหุ่นยนต์ฮิวแมนนอยด์.

การจัดการระบายความร้อนถือเป็นความท้าทายที่สำคัญอีกประการหนึ่ง. หุ่นยนต์ฮิวแมนนอยด์ผสานรวมอุปกรณ์พลังงานและโปรเซสเซอร์จำนวนมาก, เกิดความร้อนสูงระหว่างการทำงาน. เป็นเส้นทางวิกฤตสำหรับการนำความร้อน, PCB ต้องการกลยุทธ์การออกแบบการระบายความร้อนโดยใช้วัสดุที่มีการนำความร้อนสูง. PCB ระดับไฮเอนด์มักใช้ HVLP (ไฮเปอร์โปรไฟล์ต่ำมาก) ฟอยล์ทองแดงเพื่อลดการสูญเสีย, ผสมผสานกับความร้อนผ่านการออกแบบเพื่อนำความร้อนไปยังฮีทซิงค์ได้อย่างมีประสิทธิภาพ.

ความสมบูรณ์ของสัญญาณมีความสำคัญอย่างยิ่งในหุ่นยนต์ฮิวแมนนอยด์. ความแม่นยำของการเคลื่อนที่ของหุ่นยนต์อาศัยการส่งสัญญาณที่สะอาด; ความล่าช้าหรือการบิดเบือนอาจส่งผลต่อความสมดุลและการประสานงาน. การใช้วัสดุที่มีค่าคงที่ไดอิเล็กทริกต่ำ (ต่ำ-Dk) และปัจจัยการกระจายต่ำ (ต่ำ-Df), เช่น เรซินไฮโดรคาร์บอนและผ้าแก้ว Low-Dk รุ่นที่สอง, สามารถลดการลดทอนและการบิดเบือนสัญญาณได้อย่างมีประสิทธิภาพ.

03 นวัตกรรมวัสดุ: โซลูชัน PCB แบบยืดหยุ่นและแข็ง

เพื่อตอบสนองความต้องการด้านโครงสร้างที่เป็นเอกลักษณ์ของหุ่นยนต์ฮิวแมนนอยด์, วงจรพิมพ์แบบยืดหยุ่น (FPC) และบอร์ดแบบแข็งเกร็งกลายเป็นโซลูชั่นในอุดมคติ. วงจรที่ยืดหยุ่นช่วยให้ PCB สอดคล้องกับส่วนโค้งของข้อต่อหุ่นยนต์ เช่น นิ้ว, ข้อมือ, และคอ—ทำให้มีอิสระในการกำหนดเส้นทางสามมิติ. วัสดุที่มีความยืดหยุ่นความถี่สูง เช่น DuPont™ Pyralux® TK และ Panasonic FELIOS R-F775 ตรงตามข้อกำหนดด้านความน่าเชื่อถือในสถานการณ์การโค้งงอแบบไดนามิก.

บอร์ดแบบยืดหยุ่นจะให้การสนับสนุนโครงสร้างโดยยังคงรักษาระดับความยืดหยุ่นไว้, ช่วยให้เคลื่อนไหวได้คล่องตัว, สมดุล, และการปรับตัวให้เข้ากับภูมิประเทศที่ซับซ้อน. เทคโนโลยีนี้มีความสำคัญอย่างยิ่งต่อลำตัวของหุ่นยนต์, โดยจะต้องรองรับส่วนประกอบหลักในขณะที่ทนต่อแรงกดเชิงกลระหว่างการเดินและการหมุน.

ระบบนิเวศทางวัตถุก็กำลังพัฒนาเช่นกัน. ผ้าแก้วอิเล็กทรอนิกส์กำลังเปลี่ยนจากแก้ว E แบบดั้งเดิมไปเป็นแก้ว L/Q. ระบบเรซินกำลังอัปเกรด Dk/Df ให้ต่ำลงและอุณหภูมิการเปลี่ยนสถานะคล้ายแก้วสูงขึ้น (ทีจี). HVLP3/4 และฟอยล์ทองแดงบางเฉียบถูกนำมาใช้กันอย่างแพร่หลายเพื่อลดการสูญเสีย. ความก้าวหน้าทางวัสดุเหล่านี้ร่วมกันเพิ่มประสิทธิภาพความถี่สูงและความน่าเชื่อถือของ PCB หุ่นยนต์ฮิวแมนนอยด์.

04 กระบวนการขั้นสูง: ขอบเขตของ mSAP และการพิมพ์ 3 มิติ

การตอบสนองความต้องการประสิทธิภาพสูงของหุ่นยนต์ฮิวแมนนอยด์ต้องใช้กระบวนการผลิต PCB ขั้นสูงหลายชุด. กระบวนการ mSAP ได้รับการยอมรับอย่างรวดเร็วในเซิร์ฟเวอร์ AI และสลับมาเธอร์บอร์ดเพื่อให้ได้ความกว้าง/ระยะห่างของเส้น10-15μm. กระบวนการนี้เหมาะสมพอๆ กันสำหรับการผลิตมาเธอร์บอร์ดที่มีความหนาแน่นสูงสำหรับหุ่นยนต์ฮิวแมนนอยด์.

3เทคโนโลยีการพิมพ์ D นำเสนอโซลูชั่นการเปลี่ยนแปลงสำหรับ การผลิต PCB. การผลิต PCB แบบดั้งเดิมต้องเผชิญกับปัญหาคอขวดในเรื่องความสมดุลระหว่างความแม่นยำสูงและความหนาสูง. ในทางตรงกันข้าม, 3การพิมพ์ D สามารถสร้างแผงวงจรเซรามิกแนวตั้งที่มีความกว้างของเส้นที่ละเอียดกว่าและอัตราส่วนภาพเฉพาะได้, เหมาะสำหรับการผลิตแผงวงจรรูปทรงพิเศษภายในหุ่นยนต์ฮิวแมนนอยด์.

กระบวนการบัดกรีก็อยู่ระหว่างการพัฒนาเช่นกัน. ตัวอย่างเช่น, หุ่นยนต์บัดกรีแบบแทรกอัจฉริยะที่โรงงานประกอบของ UGPCB นำเสนอ ผสานรวมการระบุตำแหน่งด้วยภาพและการตรวจสอบอุณหภูมิแบบเรียลไทม์. ซึ่งจะช่วยเพิ่มประสิทธิภาพการบัดกรีถึงสามเท่าเมื่อเทียบกับวิธีการแบบแมนนวล, ด้วยอัตราการผ่านของ 99.5%. ความแม่นยำและความน่าเชื่อถือดังกล่าวเป็นสิ่งสำคัญสำหรับหุ่นยนต์ การประกอบ PCB.

ภาพด้านล่างแสดงการออกแบบสถาปัตยกรรมหลายชั้นของ PCB หุ่นยนต์ฮิวแมนนอยด์:

05 การผลิตอัจฉริยะ: โรงงานดิจิทัลที่ช่วยให้สามารถผลิต PCB คุณภาพสูง

เผชิญกับความต้องการสูงในด้านคุณภาพ PCB ที่สม่ำเสมอในหุ่นยนต์ฮิวแมนนอยด์, การผลิตอัจฉริยะกลายเป็นสิ่งจำเป็น. บริษัท PCB ชั้นนำกำลังจัดตั้งโรงงานดิจิทัลอัจฉริยะเพื่อดำเนินการ “การเปลี่ยนเครื่อง” และขับเคลื่อนด้วยข้อมูล.

ล่าสุด, โรงงานของ UGPCB ได้เพิ่มซีรีส์อัจฉริยะ, อุปกรณ์การผลิต PCB อัตโนมัติ, เช่น เครื่องเจาะด้วยเลเซอร์ซับสเตรตอะลูมิเนียม และเครื่องติดเทปพินบอร์ดหลายชั้นสองด้าน. สิ่งนี้ได้เพิ่มระดับสติปัญญาและระบบอัตโนมัติของโรงงานอย่างมีนัยสำคัญ, ปรับปรุงความแม่นยำของผลิตภัณฑ์อย่างมาก, ประสิทธิภาพการผลิต, และลดเวลาตอบสนองลงด้วย 50%.

ระบบการดำเนินการผลิต (MES), หัวใจสำคัญของการผลิตอัจฉริยะ, ทำหน้าที่เป็นผู้ดูแลที่เข้มงวด. โดยจะตรวจสอบพารามิเตอร์ที่สำคัญ เช่น อุณหภูมิ, ปัจจุบัน, และความเข้มข้นของสารเคมีแบบเรียลไทม์, ทำให้เกิดการแจ้งเตือนที่มีความเบี่ยงเบนน้อยที่สุด. ระบบการจัดการแบบดิจิทัลเต็มรูปแบบนี้ช่วยให้สามารถควบคุมแบบดิจิทัลแบบ end-to-end ตั้งแต่การรับคำสั่งซื้อไปจนถึงการจัดส่ง, ปรับปรุงความแม่นยำในการผลิตและความสม่ำเสมอของผลิตภัณฑ์ของ PCB หุ่นยนต์ฮิวแมนนอยด์อย่างมาก.

06 แนวโน้มในอนาคต: ปัจจัยขับเคลื่อนสองประการของ AI และการผลิตที่เป็นมิตรต่อสิ่งแวดล้อม

มองไปข้างหน้า, การพัฒนา PCB หุ่นยนต์ฮิวแมนนอยด์จะถูกกำหนดโดยแนวโน้มหลักสองประการ: การออกแบบที่ขับเคลื่อนด้วย AI และการผลิตที่เป็นมิตรต่อสิ่งแวดล้อม.

AI กำลังเปลี่ยนแปลงขั้นตอนการออกแบบ PCB. โมเดลแบบดั้งเดิมที่อาศัยประสบการณ์ของวิศวกรกำลังค่อยๆ เปลี่ยนไปใช้การออกแบบอัตโนมัติที่ได้รับความช่วยเหลือจาก AI. อัลกอริธึม AI สามารถปรับการจัดวางส่วนประกอบและโครงร่างการกำหนดเส้นทางให้เหมาะสมได้โดยอัตโนมัติ ตามความต้องการด้านความสมบูรณ์ของสัญญาณ, การจัดการความร้อน, และความเข้ากันได้ของแม่เหล็กไฟฟ้า (EMC).

การผลิตที่เป็นมิตรต่อสิ่งแวดล้อมกำลังกลายเป็นฉันทามติของอุตสาหกรรมเช่นกัน. ภาคการผลิต PCB กำลังเร่งการเปลี่ยนแปลงสีเขียว. บริษัทชอบ UGPCB กำลังเพิ่มประสิทธิภาพการจัดการพลังงานและเพิ่มความแม่นยำและประสิทธิภาพของผลิตภัณฑ์ผ่านนวัตกรรมทางเทคโนโลยี, การอัพเกรดกระบวนการ, และการแนะนำอุปกรณ์ใหม่. ผ่านการเพิ่มประสิทธิภาพแบบไดนามิกดังกล่าว, บริษัทแห่งหนึ่งรายงานว่าก 5% การลดการใช้พลังงานอย่างครอบคลุม, อัน 90% อัตราการรีไซเคิลขยะ, และ 30% การปล่อยน้ำเสียลดลงอย่างรวดเร็ว.

เนื่องจากกฎระเบียบด้านสิ่งแวดล้อมมีความเข้มงวดมากขึ้น, ESG (ด้านสิ่งแวดล้อม, ทางสังคม, และธรรมาภิบาล) การผลิตที่เป็นมิตรต่อสิ่งแวดล้อมที่ปฏิบัติตามข้อกำหนดไม่เพียงแต่เป็นความรับผิดชอบต่อสังคมขององค์กรเท่านั้น แต่ยังเป็นเงื่อนไขในการเข้าถึงตลาดระหว่างประเทศอีกด้วย. เป็นผลิตภัณฑ์ที่มุ่งเน้นอนาคต, ข้อมูลประจำตัวที่เป็นมิตรต่อสิ่งแวดล้อมของห่วงโซ่อุปทาน PCB ของหุ่นยนต์ฮิวแมนนอยด์จะส่งผลโดยตรงต่อภาพลักษณ์ของแบรนด์และการยอมรับของตลาด.

07 โอกาสในการสมัคร: ความต้องการหลายภาคส่วนสร้างโอกาส PCB ใหม่

สถานการณ์การใช้งานที่ขยายตัวสำหรับหุ่นยนต์ฮิวแมนนอยด์กำลังสร้างช่องทางการเติบโตใหม่สำหรับตลาด PCB.

-

การทหารและการป้องกันประเทศ: หุ่นยนต์ฮิวแมนนอยด์ช่วยเหลือในภารกิจค้นหาและกู้ภัยและการเฝ้าระวังในพื้นที่อันตราย, เพิ่มความปลอดภัยและประสิทธิภาพ. สถานการณ์เหล่านี้ต้องการ PCB ที่มีความน่าเชื่อถือสูงและมีความยืดหยุ่นต่อสิ่งแวดล้อม.

-

การผลิตและโลจิสติกส์: หุ่นยนต์ทำงานที่เป็นอันตรายหรือทำซ้ำๆ เพื่อเพิ่มความยืดหยุ่นของพนักงาน และรับประกันการควบคุมคุณภาพผ่านการตรวจจับข้อบกพร่องที่ขับเคลื่อนด้วย AI. ซึ่งต้องใช้ PCB ที่รวมเซ็นเซอร์จำนวนมากและอินเทอร์เฟซการสื่อสารความเร็วสูง.

-

ความช่วยเหลือในบ้านและการใช้งานส่วนบุคคล: ความต้องการของผู้บริโภคที่เพิ่มขึ้นสำหรับหุ่นยนต์ที่จัดการงานบ้านและให้การตรวจสอบความปลอดภัยทำให้ความต้องการความคุ้มทุนและความน่าเชื่อถือของ PCB สูงขึ้นสำหรับแอปพลิเคชันระดับผู้บริโภค.

-

การศึกษาและการดูแลสุขภาพ: การแนะนำหุ่นยนต์ฮิวแมนนอยด์อย่างค่อยเป็นค่อยไปในด้านเหล่านี้ช่วยขยายขอบเขตการใช้งาน PCB ต่อไป. การวิจัยระบุว่าตลาดการออกแบบ PCB หุ่นยนต์ฮิวแมนนอยด์ทั่วโลกมีแนวโน้มการเติบโตที่สำคัญ, โดยยุโรปคาดว่าจะขึ้นนำด้วย 6.9% cagr.

ในปีต่อๆ ไป, ด้วยการลงทุนด้านพลังประมวลผล AI อย่างต่อเนื่อง, อุตสาหกรรม PCB หุ่นยนต์ฮิวแมนนอยด์จะเข้าสู่ระยะใหม่ที่โดดเด่นด้วย “การพัฒนาที่ขับเคลื่อนด้วยเทคโนโลยีและการปรับสมดุลระดับภูมิภาค” ผู้นำในอุตสาหกรรมที่มีความสามารถในการผลิตระดับสูง, เครือข่ายการจัดส่งในต่างประเทศ, และระบบวัสดุที่เสริมฤทธิ์กันจะมีความได้เปรียบทางการแข่งขันในวงจรนี้.

สำหรับบริษัทที่ต้องการเข้าสู่สาขานี้, ตอนนี้เป็นช่วงเวลาสำคัญในการลงทุนในระดับไฮเอนด์ ความจุของพีซีบี และยึดครองพื้นที่สูงทางเทคโนโลยี. มีเพียงซัพพลายเออร์ที่เชี่ยวชาญกระบวนการขั้นสูงและมีความสามารถในการตอบสนองที่รวดเร็วเท่านั้นที่จะกลายมาเป็นผู้รับประโยชน์ในยุคแห่งการแพร่กระจายของหุ่นยนต์ฮิวแมนนอยด์ที่กำลังจะเกิดขึ้น.

โลโก้ UGPCB

โลโก้ UGPCB