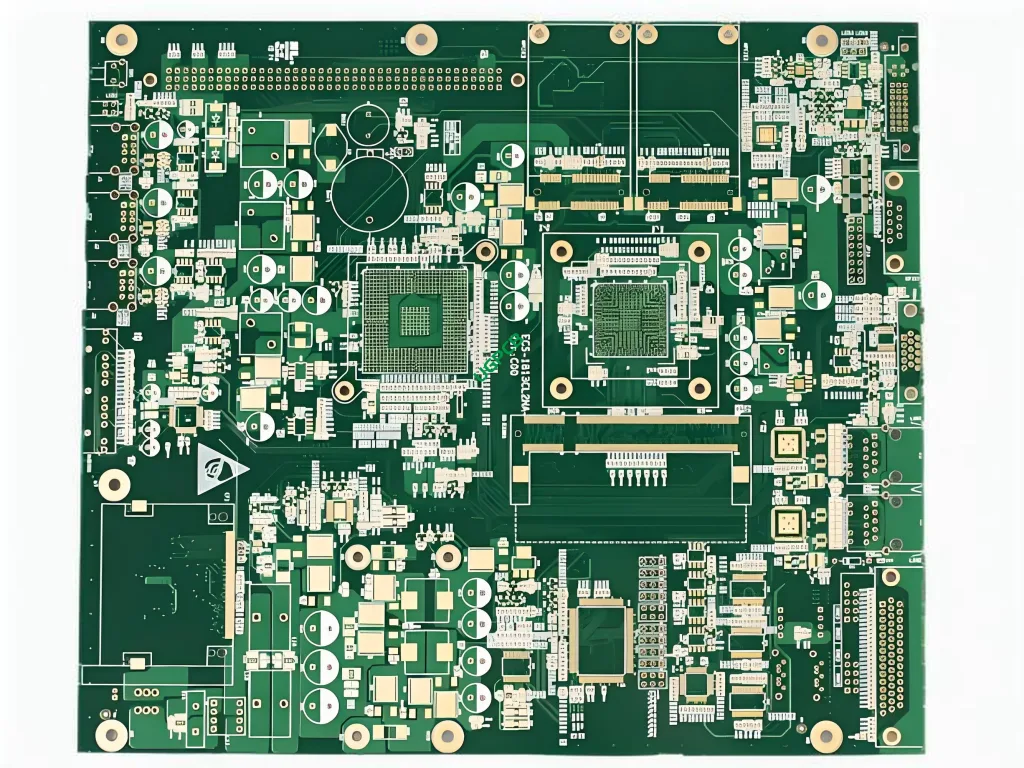

Introduction to the Industrial Controller PCB

The Industrial Controller PCB is a robust and reliable placa de circuito impreso designed specifically for industrial control systems. It ensures stable and efficient operation in demanding environments, making it essential for various industrial applications.

What is an Industrial Controller PCB?

An Industrial Controller PCB, o placa de circuito impreso, is a specialized electronic board used in industrial control systems. It houses various components and provides the necessary interconnections to ensure the proper functioning of industrial machinery and processes.

Requisitos de diseño

The design requirements for an Industrial Controller PCB are critical to ensure its reliability and performance:

- Material: EM-82, chosen for its durability and excellent electrical properties.

- Recuento de capas: 4 layers to accommodate complex circuit designs.

- Color: Black/White for easy identification and aesthetic appeal.

- Espesor terminado: 1.6mm to provide structural integrity without being overly bulky.

- Espesor de cobre: 1OZ to ensure adequate conductivity.

- Tratamiento superficial: Oro de inmersión para mejorar la soldabilidad y la resistencia a la corrosión..

- Minimum Trace and Space: Both 6mil (0.15milímetros) to support fine circuit patterns.

- Característica: Hole copper is larger than 25um for better electrical connectivity.

¿Cómo funciona??

The Industrial Controller PCB works by providing a platform for various electronic components to be interconnected through conductive pathways. These pathways, or traces, are made of copper and are etched onto the board. The immersion gold surface treatment ensures that these traces remain conductive and resistant to environmental factors.

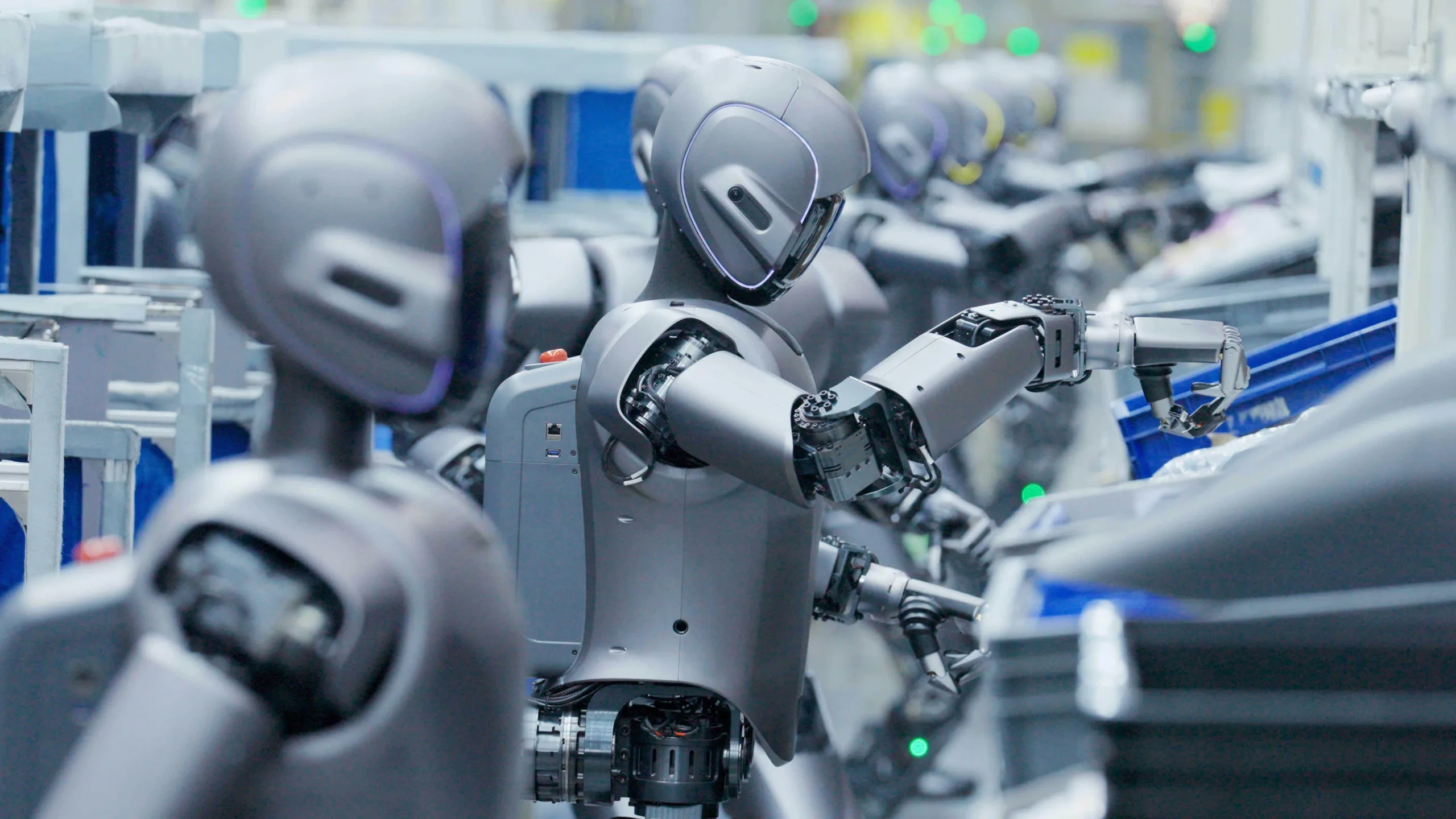

Aplicaciones

The primary application of the Industrial Controller PCB is in industrial control systems where it manages and regulates the operations of machinery and processes. This includes:

- Automated manufacturing systems

- Industrial robotics

- Process control systems

- Machine tool controllers

Clasificación

Según sus características y aplicaciones., the Industrial Controller PCB can be classified as a high-reliability PCB designed for industrial use. This classification highlights its capability to withstand harsh industrial environments.

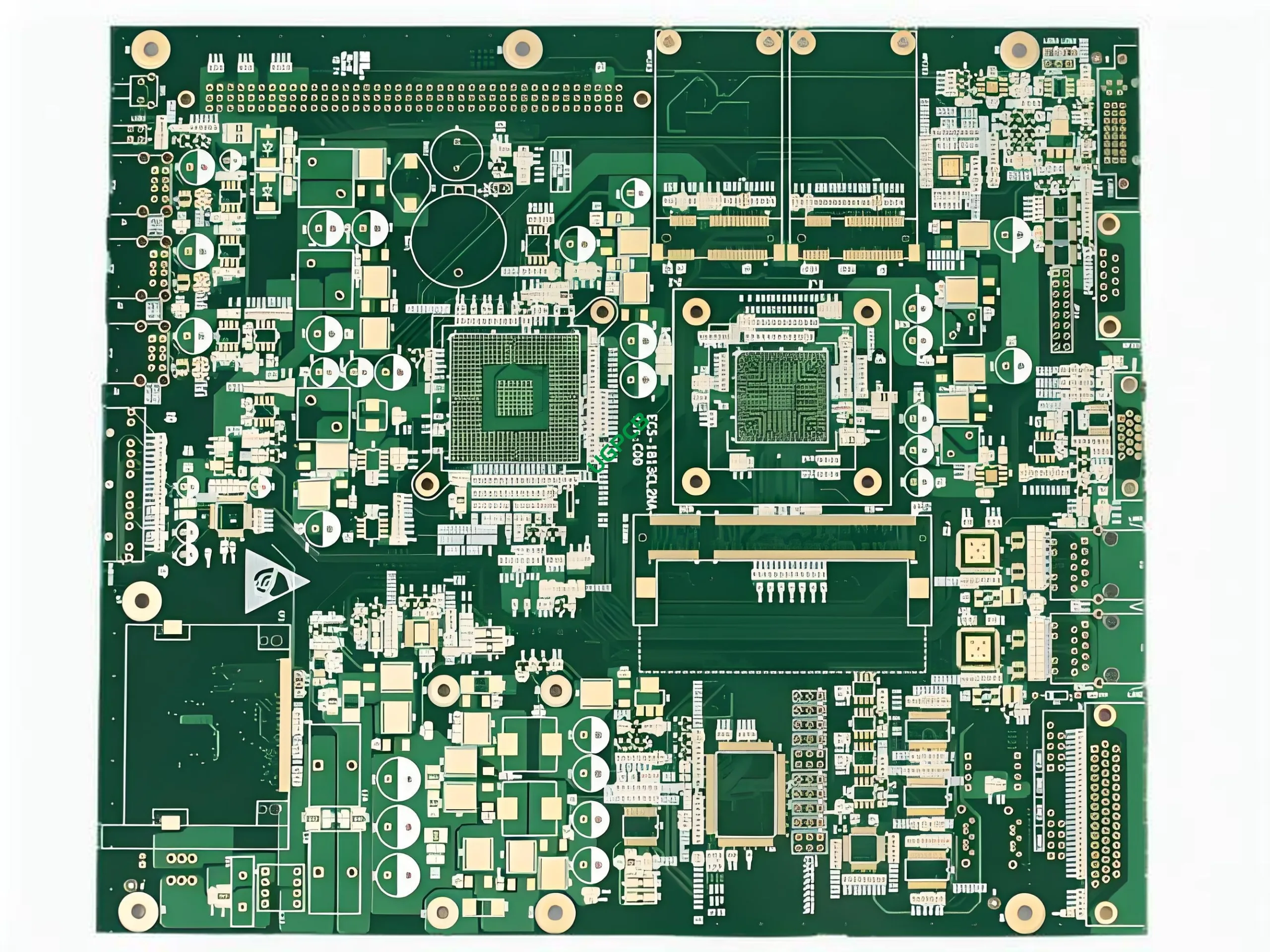

Composición de materiales

el núcleo material used in the Industrial Controller PCB is EM-82, un material laminado de alto rendimiento conocido por su excelente mecánica, térmico, y propiedades electricas. This material ensures that the PCB can withstand the demands of industrial applications.

Características de rendimiento

The performance characteristics of the Industrial Controller PCB include:

- Alta confiabilidad

- Excelente integridad de la señal

- Gestión térmica superior

- Robust mechanical strength

- Long-term stability

Detalles estructurales

The structural details of the Industrial Controller PCB are as follows:

- Recuento de capas: 4 capas

- Espesor terminado: 1.6milímetros

- Espesor de cobre: 1ONZ

- Ancho mínimo de traza: 6mil (0.15milímetros)

- Espacio mínimo entre pistas: 6mil (0.15milímetros)

- Tratamiento superficial: Oro de inmersión

- Hole Copper Thickness: Larger than 25um

Características y beneficios

The key features and benefits of the Industrial Controller PCB include:

- Interconectividad de alta densidad

- Excelente integridad de la señal

- Construcción mecánica robusta

- Rendimiento confiable a largo plazo

- Opciones de color estético (Negro/negro)

Proceso de producción

The production process of the Industrial Controller PCB involves several steps, incluido:

- Selección de material: Choosing high-quality EM-82 material.

- Apilamiento de capas: arreglando el 4 capas con precisión.

- Aguafuerte: Eliminar el exceso de cobre para formar los patrones de traza deseados..

- Enchapado: Aplicando el tratamiento de la superficie de oro de inmersión.

- Asamblea: Incorporación de PTH y vías para interconexiones de capas..

- Pruebas: Garantizar que la PCB cumpla con todas las especificaciones de rendimiento.

Casos de uso

The Industrial Controller PCB is used in various scenarios, como:

- Automated manufacturing lines

- Industrial robot control systems

- Process control equipment

- Machine tool automation

En resumen, the Industrial Controller PCB is a sophisticated and reliable component designed to meet the demanding requirements of industrial control systems. Su diseño de alta densidad, excelentes características de rendimiento, and robust construction make it an essential part of any advanced industrial setup.

UGPCB LOGO

UGPCB LOGO