Introduction to Different Solder Mask Colors Overview

Different solder mask colors are essential components in the manufacturing of placas de circuito impreso (PCB), playing a crucial role in protecting circuits and enhancing the aesthetic appeal of electronic devices. Available in a variety of materials, colors, and configurations, these solder masks cater to diverse application needs, Asegurar un rendimiento confiable y durabilidad.

Composición de materiales

The Different solder mask colors are primarily made from two materials: FR-4 and teflón.

- FR-4: A flame-retardant epoxy glass cloth laminate, known for its high mechanical strength, aislamiento eléctrico, and thermal resistance. It’s ideal for applications requiring high reliability and durability.

- teflón: A polytetrafluoroethylene (PTFE) based material, renowned for its excellent chemical resistance, non-stick properties, and wide operating temperature range. Teflon is often used in specialized applications demanding high performance and corrosion resistance.

Características de rendimiento

These solder masks offer a range of performance characteristics tailored to meet different requirements:

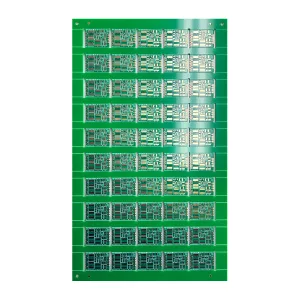

- Configuración de capa: Available in single-layer to PCB multicapa configurations, enabling flexible design options for various electronic devices.

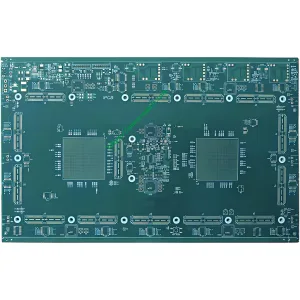

- Color Options: Multiple colors ensure aesthetic versatility, allowing manufacturers to match product designs with specific branding or aesthetic preferences.

- Espesor terminado: Que se extiende desde 0.1 to 6.0mm, offering flexibility in accommodating various PCB thicknesses and assembly processes.

- Espesor de cobre: De 0.5 to 6OZ, ensuring compatibility with different current carrying capacities and design requirements.

- Tratamiento superficial: Options include Gold and OSP (Conservantes de soldadura orgánica), providing excellent solderability and corrosion resistance.

Diseño estructural

The structural design of Different solder mask colors is optimized for functionality and durability:

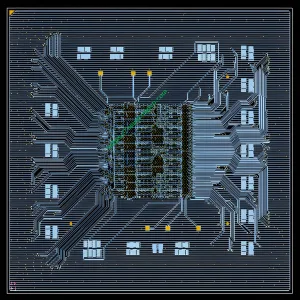

- Min Trace and Space: With minimum trace and space widths of 1.5mil-4mil, these masks support high-density circuit layouts, essential for modern electronic devices.

- Durabilidad: The materials and processing techniques ensure the masks can withstand soldering temperatures and environmental stresses, maintaining integrity and protecting circuits over time.

Proceso de producción

The production of Different solder mask colors involves several precise steps:

- PCB Preparation: El base PCB material is prepared according to the specified layer configuration, espesor, and copper weight.

- Aplicación de máscara de soldadura: The chosen solder mask material (FR-4 or Teflon) is applied evenly over the PCB surface, either through screen printing, curtain coating, or dipping processes.

- Drying and Curing: The applied mask is dried and cured under controlled conditions to ensure adhesion and durability.

- Inspection and Testing: Quality control checks ensure the mask meets specifications, including visual inspections, thickness measurements, and solderability tests.

- Tratamiento superficial: Final surface treatments like Gold plating or OSP application are carried out to enhance solderability and corrosion resistance.

Escenarios de aplicación

Different solder mask colors find extensive applications across various electronic products:

- Electrónica de Consumo: From smartphones and tablets to laptops and wearables, these masks protect circuits and enhance the aesthetic appeal of consumer devices.

- Electrónica Industrial: In automation systems, PLC, y controladores industriales, the masks ensure reliable performance and longevity in harsh environments.

- Electrónica automotriz: In advanced driver assistance systems (ADA), sistemas de infoentretenimiento, and other automotive electronics, the masks provide essential circuit protection and aesthetic uniformity.

- Telecomunicaciones: En enrutadores, módems, and other telecommunications equipment, the masks support high-density circuit layouts and ensure signal integrity.

Different solder mask colors offer a versatile and reliable solution for protecting and enhancing the performance of electronic circuits, catering to the diverse needs of modern electronic devices.

UGPCB LOGO

UGPCB LOGO