UGPCB Enhances Multilayer PCB Manufacturing with Advanced Brown Oxide Lines

In the highly competitive world of tarjeta de circuito impreso and PCBA manufacturing, UGPCB has consistently demonstrated its commitment to excellence through strategic technological investments. The recent installation of state-of-the-art brown oxide treatment lines represents a significant milestone in our ongoing mission to deliver superior quality and reliability. This enhancement to our production capabilities specifically addresses the critical demands of multicapa fabricación de PCB, where interlayer adhesion quality directly determines final product performance.

The Critical Role of Brown Oxide Treatment in PCB Manufacturing

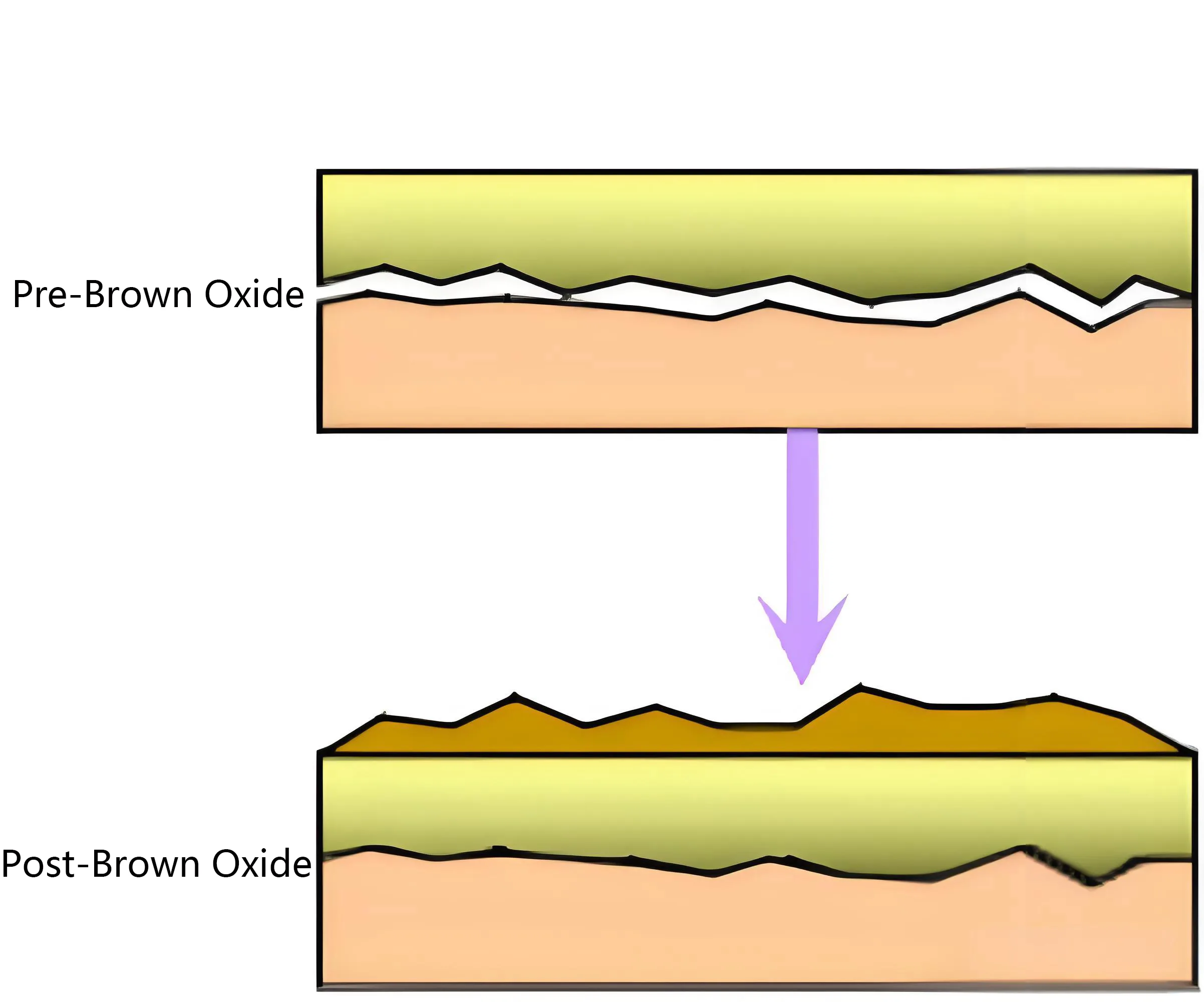

Brown oxide treatment, often called browning, is an essential chemical process in PCB multicapa production that prepares inner layer copper surfaces for lamination. This crucial step creates a microscopically rough surface with polar properties that significantly enhances the bond between copper foil and resin-based prepreg (PÁGINAS) materiales.

The fundamental chemical reactions involved are:

-

Primary formation: Cu + H₂O → CuO + H₂

-

Secondary formation: 2Cu + H₂O → Cu₂O + H₂

En UGPCB, our advanced process precisely controls the formation of both copper oxide (CuO) y cobre(I) oxide (Cu₂O) to achieve optimal results. The brown oxide layer serves multiple essential functions:

-

Increases surface area through micro-etching, creating a uniform nodular structure that enhances mechanical interlocking.

-

Converts non-polar copper surfaces to polar compounds that form stronger chemical bonds with resin systems

-

Prevents delamination by creating a thermal barrier that withstands high lamination temperatures

-

Eliminates contaminants that could compromise bond integrity

Technical Specifications of UGPCB’s Advanced Brown Oxide Line

UGPCB’s new brown oxide treatment system represents the cutting edge in surface treatment technology, with precision controls that far exceed conventional systems:

| Parámetro | Standard Equipment | UGPCB Advanced Line |

|---|---|---|

| Process Control Tolerance | ± 15% | ±3% |

| Micro-etching Rate Consistency | 0.3-0.6 μm | 0.4-0.5 μm |

| Capacidad de producción | 500 panels/shift | 1,200 panels/shift |

| Chemical Consumption Monitoring | Manual | Automated IoT Sensors |

| Temperature Control | ±5°C | ±0.5°C |

| Solution Analysis Frequency | 4-hour intervals | Continuous monitoring |

Our system features fully automated panel handling that minimizes human intervention and potential damage to delicate inner layers. The integrated real-time monitoring system tracks critical parameters including chemical concentration, temperatura, and immersion times, ensuring consistent results across every production batch.

Why UGPCB’s Brown Oxide Process Delivers Superior Results

Enhanced Multilayer Reliability for Critical Applications

The superiority of UGPCB’s brown oxide treatment translates directly to improved product performance in demanding applications:

-

Peel strength enhancement: Our process achieves post-lamination direct peel strength ratings exceeding 6.0 lb/in, significantly higher than the 4.5 lb/in typical of black oxide processes

-

Pink ring prevention: Through precise control of oxide layer thickness and composition, UGPCB’s process virtually eliminates pink ring defects that plague conventional treatments

-

Integridad de señal mejorada: The controlled surface roughness reduces skin effect losses at high frequencies, critical for Servidores AI, 5G Infraestructura, and high-speed networking applications

Advanced Process Control for Consistent Quality

UGPCB’s brown oxide line incorporates sophisticated control systems that maintain optimal process conditions:

-

Automated chemical dosing maintains bath concentration within ±2% of target values

-

Multi-stage rinsing with conductivity monitoring ensures complete contaminant removal

-

In-line optical inspection verifies oxide layer quality and color consistency on every panel

-

Digital twin simulation predicts maintenance needs before quality deviations occur

UGPCB’s Technical Edge in PCB and PCBA Manufacturing

Comprehensive Capabilities Beyond Surface Treatment

While our advanced brown oxide lines represent a significant achievement, they are just one component of UGPCB’s comprehensive manufacturing ecosystem:

-

Specialized materials expertise: We maintain extensive process parameters for various copper foil types, incluido Hte, VLP, and HVLP foils, each requiring customized treatment approaches

-

High-density interconnect (IDH) capabilities: UGPCB supports 3/3 mil line/space rules for demanding consumer and industrial applications

-

Advanced testing protocols: Every production batch undergoes rigorous ion contamination testing, thermal stress evaluation, and peel strength verification

Driving Innovation in PCB Technology

UGPCB actively contributes to industry advancement through:

-

Materials research: Collaboration with leading substrate manufacturers to develop next-generation dielectric materials

-

Process optimization: Implementation of AI-assisted design analysis that identifies potential lamination issues before production

-

Sustainability leadership: Our brown oxide process incorporates closed-loop rinsing water recovery y copper ion reclamation systems that capture 90% of process metals for recycling

The UGPCB Advantage: Why Industry Leaders Trust Our PCBA Solutions

Seamless Integration from PCB Fabrication to Assembly

UGPCB offers unparalleled value through vertically integrated PCB and PCBA services:

-

Diseño para la fabricación (DFM) feedback: Our engineering team provides expert guidance on stackup planning, selección de material, and design optimization for enhanced reliability

-

Single-source accountability: From inner layer brown oxide treatment to final assembly, UGPCB maintains quality control throughout the entire manufacturing process

-

Rapid prototyping to volume production: Flexible manufacturing lines accommodate both 24-hora quick-turn prototypes and high-volume production runs

Quantifiable Business Benefits

Partnering with UGPCB delivers measurable advantages:

-

12% reduction in total cost through optimized material utilization and reduced rejection rates

-

35% improvement in mean time between failures in field applications

-

98.5% on-time delivery rate across all order volumes

-

50% faster time-to-market through streamlined engineering processes

Future-Ready Manufacturing for Emerging Applications

UGPCB’s technology roadmap aligns with evolving industry requirements:

-

AI and server applications: Our processes are optimized for the exacting requirements of AI server PCBs, which command 3x the value of traditional server boards

-

Electrónica automotriz: Certified processes for automotive applications where reliability under thermal cycling is critical

-

High-frequency designs: Controlled dielectric properties with Dk values of 4.2-4.7 and Df ≤0.015 at 1GHz

Conclusión: Partner with UGPCB for Your Critical Multilayer PCB Requirements

UGPCB’s investment in advanced brown oxide technology reflects our fundamental commitment to manufacturing excellence. By mastering this crucial process step, we ensure the structural integrity and long-term reliability of the multilayer PCBs that power today’s most demanding electronic systems.

Experience the UGPCB difference in your next PCB or PCBA project. Contact our technical team today to discuss how our brown oxide capabilities and comprehensive manufacturing expertise can enhance your product reliability and performance.

UGPCB LOGO

UGPCB LOGO