RIDID-FLEX PCB: 고밀도 전자 제품을위한 우주 절약 솔루션

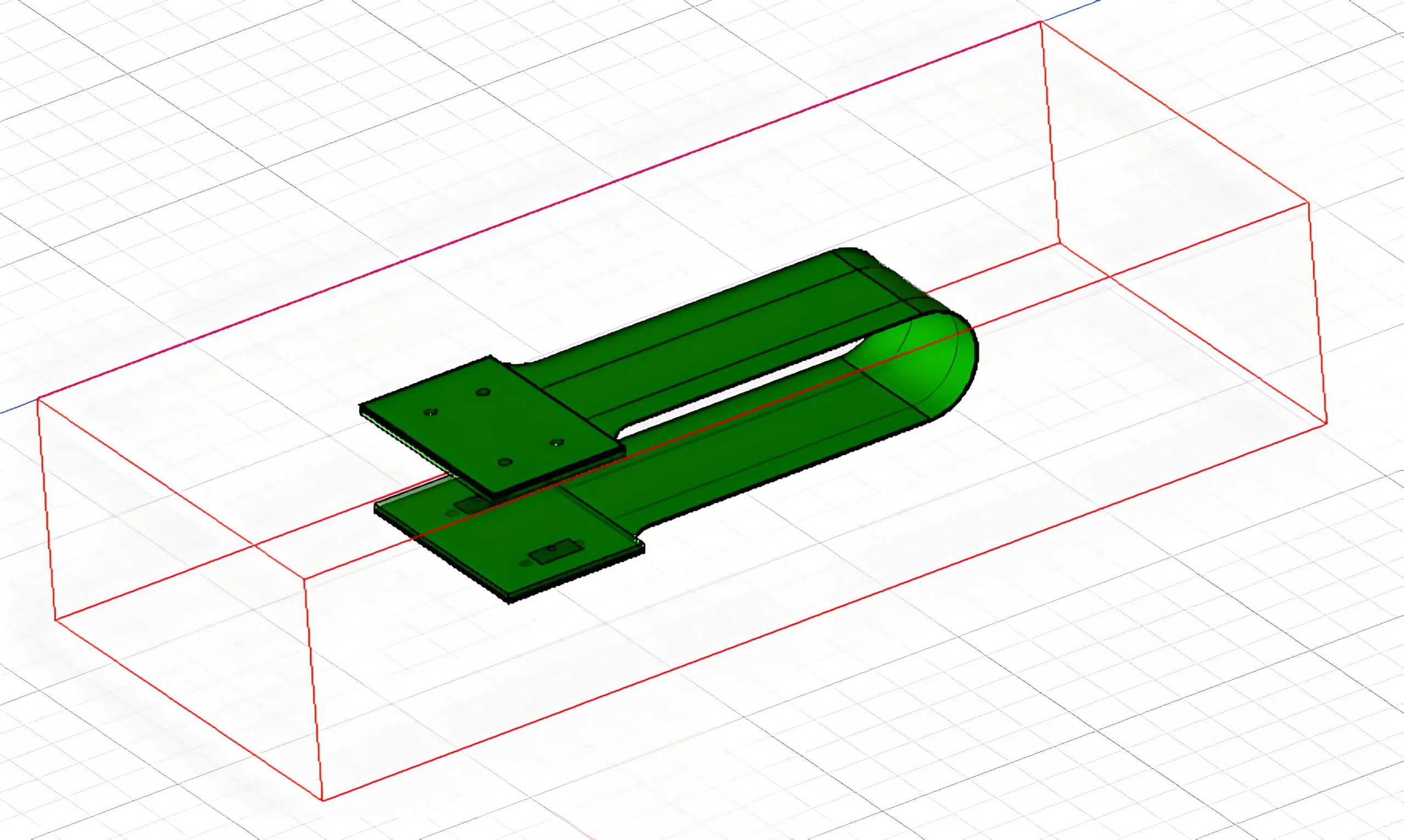

장치 소형화의 끊임없는 추구에서, 체중 감소, 그리고 향상된 신뢰성, RIDID-FLEX PCB 기술 참신함에서 최첨단 응용 분야의 필수 요구 사항으로 발전했습니다.. 이 혁신적인 구조는 강성 PCB의 안정적인 지원을 유연한 PCB의 변형의 자유와 결합합니다. (FPC), PCB 디자이너에게 전례없는 3D 라우팅 기능을 부여합니다. PCB 및 PCBA 제조에 대한 10 년 이상의 전문 지식으로, UGPCB 깊이 이해합니다: 권리를 선택합니다 RIDID-FLEX PCB 설계 그리고 제조업체는 제품 성공을 향한 중요한 단계입니다!

Rigid-Flex PCB가 고급 장치의 최고의 선택 인 이유?

-

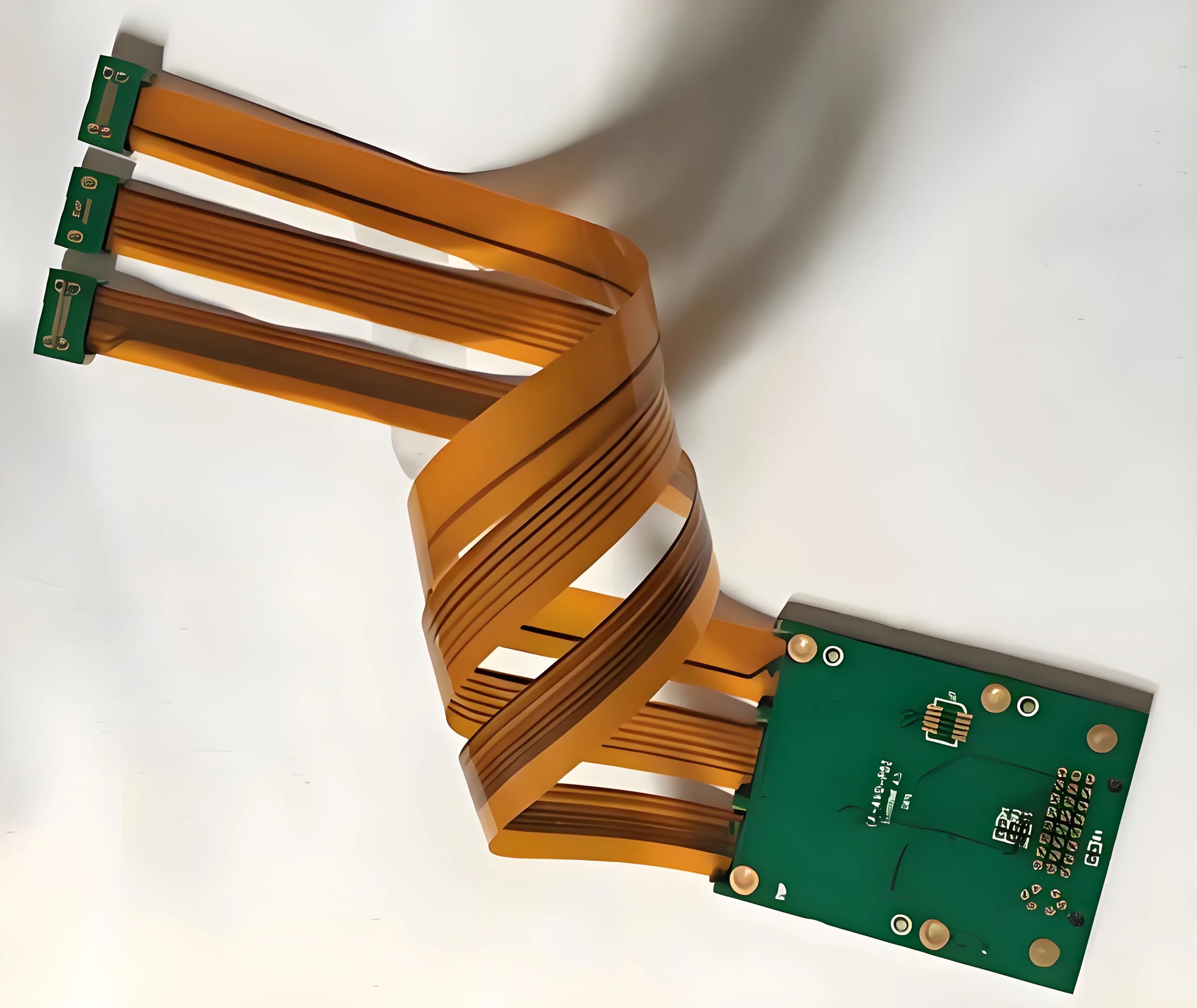

혁신적인 우주 활용: 장치 내에서 종이 접기 예술과 같은 회로 보드를 굽히고 접는 것을 상상해보십시오.. 이것은 z 축 치수를 해방시킵니다, 복잡한 회로 시스템의 통합 가능 - 전통적으로 여러 개의 별도가 필요한 PCB, 케이블, 커넥터 - 단일, 소형 조립. 디자인 자유는 극적으로 증가합니다, 장치 크기와 무게는 크게 감소합니다.

-

타의 추종을 불허하는 연결 신뢰성: 커넥터와 케이블은 기존 설정에서 일반적인 고장 지점입니다.. Ridid-Flex PCB는 이러한 물리적 상호 연결 지점을 제거합니다. 신호는 유연한 기판 내에서 지속적으로 이동합니다, 전체 시스템 안정성과 충격/진동 저항을 크게 향상시킵니다. 이것은 항공 우주와 같은 가혹한 환경에 이상적입니다, 방어, 이식 가능한 의료 기기.

-

최적화 된 성능 & 비용 균형: 초기 비용은 표준 강성 PCB보다 높지만, 산업 프로세스 (PCB 재료, 장비, 조작) 계속 성숙하십시오, 꾸준히 비용을 낮추고 있습니다. 결정적으로, Ridid-Flex PCB는 여러 구성 요소를 통합합니다, 어셈블리를 단순화하십시오, 수율을 향상시킵니다. 시스템 관점에서, 총 소유 비용 (TCO) 복잡한 PCB 및 PCBA 프로젝트에 경쟁이 치열 해집니다.

깊은 다이빙: 물리적 특성 & Rigid-Flex PCB의 설계 과제

재료 융합: 안정성의 기초와 도전

Rigid-Flex PCB 제조의 핵심은 다른 재료의 완벽한 결합에 있습니다.:

-

엄격한 지역: 일반적으로 FR4 에폭시 글라스 라미네이트를 사용합니다 (CTE ≈ 14-17 ppm/°C).

-

유연한 지역: 폴리이 미드를 사용하십시오 (PI, CTE ≈ 12-20 ppm/°C) 또는 폴리 에스테르 (애완 동물) 영화.

-

주요 도전: 열 팽창 계수 차이 관리 (CTE) 재료 사이, 강력한 접착제 인터페이스 결합 보장, 라미네이션 동안 치수 안정성을 제어합니다. 결합이 좋지 않으면 박리와 균열이 발생합니다, 제품 수명에 심각하게 영향을 미칩니다.

UGPCB 솔루션: 우리는 고성능 수정 에폭시 또는 아크릴 접착제 시스템을 엄격하게 선택합니다.. 이 재료는 FR4와 PI/PET 사이의 성능 간격을 연결하도록 특별히 최적화되었습니다., 열 사이클링 및 기계적 응력 하에서 탁월한 층간 접착력 및 안정성 제공. 재료 선택은 IPC-6013D 및 IPC-2223B 표준에 대해 엄격하게 검증됩니다..

스트레스 관리: 3D 공간의 보이지 않는 도전

Ridid-Flex PCB의 고유 한 3D 구성은 응용 프로그램 중에 다축 응력에 적용됩니다. (예를 들어, 반복적 인 굴곡, 역동적 인 움직임):

-

xy 축 스트레스: 보드 평면 내 인장/압축력.

-

축 축 응력: 인터레이어 껍질을 벗기는 힘, 특히 벤드 전이 구역에서 중요합니다 (굽힘 반경

R핵심입니다!). 굽힘 반경이 부족하거나 설계가 좋지 않으면 구리 골절 또는 커버 레이 주름이 발생할 수 있습니다.. -

주요 공식 – 최소 굽힘 반경 (

Rmin) 경험의 규칙: 동적 굴곡 응용 프로그램의 경우,Rmin ≥ 10 * t(어디t= 총 플렉스 층 두께). 설치를 위해 (일회성 또는 거의 구부러진),Rmin ≥ 6 * t. 정확한 계산은 구리 중량을 고려해야합니다, PI 두께, 레이어 스택 업, 특정 물질 연성.

UGPCB 이점: 우리의 엔지니어링 팀은 유한 요소 분석에서 탁월합니다 (fea) 시뮬레이션. 설계 단계에서 벤드 영역의 응력 분포를 예측하고 최적화합니다., 제품이 가장 엄격한 Flex Life 요구 사항을 충족하는지 확인합니다 (예를 들어, >100,000 동적 벤드 사이클).

대체 태그 제안: rigid-flex-pcb-stress-analysis-bend-region-fea (벤드 전환에서 임계 영역을 강조하는 FEA 스트레스 윤곽선 표시 이미지)

프로세스 복잡성: 높은 장벽은 높은 가치를 만듭니다

Ridid-Flex PCB 생산에는 표준 강성 또는 순수 플렉스 보드보다 훨씬 더 많은 단계가 포함됩니다., 정밀 제조의 정점을 나타냅니다:

-

긴, 다단계 프로세스: 강성 및 플렉스 구역의 교대 처리가 필요합니다, 여러 라미네이션이 포함됩니다, 교련, 도금, 표지 응용 프로그램, 그리고 윤곽 라우팅 (갈기 + 레이저 절단).

-

극단적 인 등록 정확도: 다른 재료는 처리 중에 다양한 차원 변화율을 나타냅니다, 계층 간 정렬에 대한 정확한 보상을 요구합니다.

-

양보 도전: 통계는 일반적인 4 층 Ridid-Flex PCB 테이크를 보여줍니다 5-7 동일한 층 수의 표준 강성 PCB보다 제조에 더 길다.. 이러한 복잡성은 직접 생산 비용이 더 높아지고 PCB 제조업체의 뛰어난 기술 능력이 필요합니다..

UGPCB 코어 기능: 10 년 동안의 산업 초점으로 인해 우리는 전용 Rigid-Flex PCB 생산 라인 및 프로세스 제어 시스템을 구축 할 수있었습니다.. 고정밀 라미네이션 프레스에서 (온도/압력 프로파일 링) 플렉스 재료를위한 특수 도금 라인 (균일 홀 구리 보장), 레이저 직접 이미징 (LDI) 그리고 레이저 절단, 모든 장비는 강성 팩스 특성에 최적화되어 있습니다. 이것은 높은 수율을 보장합니다 (>85%) 신뢰할 수있는 일관성 PCBA 조립.

방대한 응용 프로그램: Rigid-Flex PCB가 뛰어나는 곳

Rigid-Flex PCB의 독특한 가치 제안은 “보이지 않는 챔피언” 이 까다로운 분야에서:

-

항공우주 & 방어: 미사일 안내 시스템, 위성 페이로드, 공중 레이더/통신 장비 - 극도의 신뢰성이 필요합니다, 가벼운, 그리고 높은 충격/진동에 대한 저항.

-

고급 의료 기기: 내시경, 맥박 조정기, 신경 자극기, 휴대용 진단 - 소형화의 위치, 생체 적합성, 장기 임플란트 신뢰성이 가장 중요합니다.

-

플래그십 소비자 전자 장치: 접이식 스마트 폰의 힌지 영역 회로, 초박형 노트북 힌지 연결, TWS 이어 버드 충전 케이스/상호 연결, 액션 카메라, 고밀도 웨어러블-궁극적 인 공간 절약 및 세련된 형태 요인 추구.

-

산업용 & 자동차 전자: 산업용 로봇 조인트 배선, 자동차 카메라 모듈, ADAS 센서, EV 배터리 관리 시스템 (BMS) - 진동을 견딜 필요가 있습니다, 열 사이클링, 그리고 단단한 공간 제약.

UGPCB: 고급 Rigid-Flex PCB 설계를위한 신뢰할 수있는 파트너 & 조작

전문 PCB 및 PCBA 공급 업체로서 10 수년간의 산업 경험, UGPCB는 Ridid-Flex 기술을 핵심 역량으로 간주합니다. 우리는 고객에게 원활한 것을 제공하기 위해 최선을 다하고 있습니다, 설계에서 볼륨 생산까지 원 스톱 솔루션.

우리의 핵심 장점

-

입증 된 디자인 전문 지식: 우리의 엔지니어링 팀은 IPC-2223 및 IPC-6013과 같은 Rigid-Flex 설계 표준을 마스터합니다.. 우리는 주요 과제를 신속하게 해결합니다: 굽힘 반경 계산, 스택 업 계획, 재료 선택, 스트레스 릴리프 설계-실패 위험 완화 및 시장 시간 단축 (TTM).

-

강력한 제조 능력: 전용 RID-FLEX 생산 라인이 장착되어 있습니다. 우리는 중요한 프로세스를 엄격하게 통제합니다: 재료 소싱 (RoHS 규제 & 맞춤형 에코 준수), 다층 정밀 정렬 (≤ ± 50μm), 제어 된 라미네이션, 미세한 가공 (레이저/기계식 드릴링). 제품이 높은 신뢰성 요구를 충족시켜줍니다 (Halt/Hass 테스트 지원).

-

균형 잡힌 속도 & 비용: 최적화 된 프로세스와 스케일링 생산은 업계 평균에 비해 리드 타임을 크게 줄입니다., 비용 효율적인 제공, 고급 PCB 및 PCBA 솔루션.

-

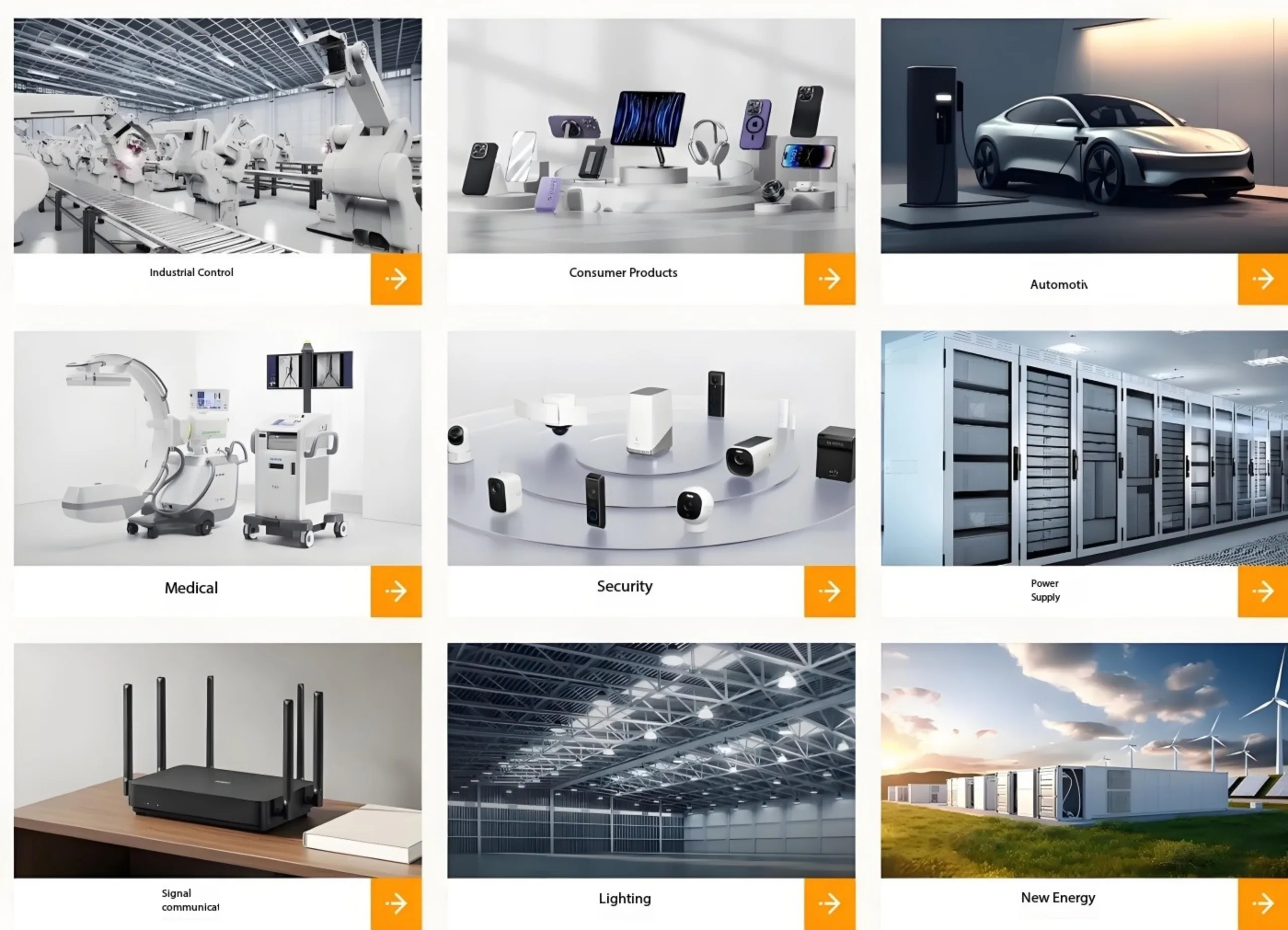

산업 간 신청 경험: 커뮤니케이션 기지국에서 널리 사용되는 제품, 산업 제어 시스템, 자동차 전자 (특히 EV 파워 트레인 시스템), 고급 전력 모듈, 스마트 보안 장치. 전 세계적으로 인정 된 품질로 프리미엄 EU/미국 시장으로 수출되었습니다.

-

엄격한 품질 시스템: 포괄적 인 품질 관리 시스템은 IQC에서 OQC에 걸쳐 있습니다, 원자재를 덮습니다, 처리 중의 점검, 및 최종 제품 검사. 전달 된 모든 Rigid-Flex PCB에 대한 안정적인 성능과 안정적인 품질을 보장합니다..

지금 조치를 취하십시오 & 제품의 잠재력을 잠금 해제하십시오!

복잡한 전자 설계 문제에 직면합니다? Rigid-Flex PCB 파트너로 UGPCB를 선택하는 것은 자신감과 성공을 선택하는 것을 의미합니다.. 우리는 회로 보드뿐만 아니라 전달합니다, 그러나 귀하의 혁신을위한 견고한 제조 재단.

특정 프로젝트 요구 사항이나 질문이 있습니다?

-

rfq를 보내십시오: sales@ugpcb.com

-

📞 전문가에게 전화하십시오: +86-135 4412 8719

-

💬 영업/엔지니어와 온라인으로 채팅하십시오

주저하지 마십시오! 우리의 영업 및 엔지니어링 팀은 다음을 제공 할 것입니다 경쟁적인 견적 이내에 24 시간. UGPCB가 우수한 Rigid-Flex PCB 설계 및 제조를 통해 전자 혁신 리더십을 강화하도록하십시오.!

UGPCB 로고

UGPCB 로고

위챗

WeChat으로 QR 코드를 스캔하세요