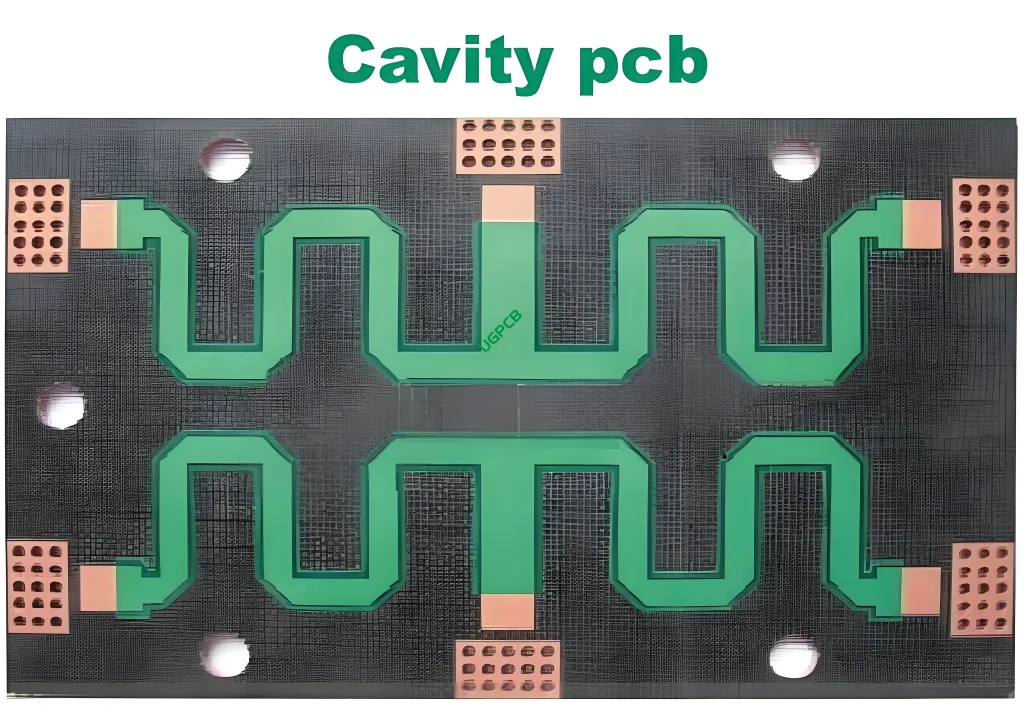

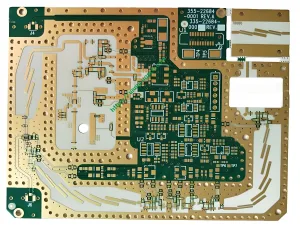

Visão geral do PCB de cavidade

PCB de cavidade, um tipo especializado de placa de circuito impresso (PCB), foi projetado para atender aos rigorosos requisitos de aplicações de alta frequência e micro-ondas. Utilizando Teflon F4MB como seu material principal, este produto está em conformidade com a classe IPC6012 2 padrão de qualidade, garantindo desempenho confiável e durabilidade.

Definição e especificações -chave

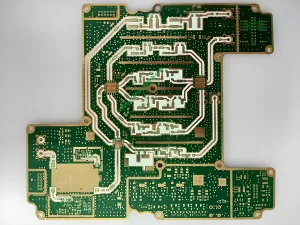

Um PCB de cavidade é caracterizado por sua estrutura de cavidade única, que é criado pela remoção de uma porção do material dielétrico para formar uma área oca. Este design é crucial para aplicações específicas como divisores de energia, onde o controle preciso sobre a distribuição do sinal é necessário. A constante dielétrica do Teflon F4MB é 2.55, fornecendo transmissão de sinal estável. As características do tabuleiro 2 camadas, com espessura total de 1,5mm. A espessura do cobre é especificada em uma base de 0,5 onças e uma espessura final de 1 onça, garantindo condutividade eficiente. A tecnologia de superfície utilizada é Immersion Silver, que oferece excelente soldabilidade e confiabilidade.

Considerações de design

Ao projetar uma PCB de cavidade, vários fatores devem ser levados em conta:

- Dimensões da Cavidade: O tamanho e a forma da cavidade devem ser definidos com precisão para atender aos requisitos da aplicação.

- Material dielétrico: Teflon F4MB é escolhido por sua baixa constante dielétrica e tangente de perda, tornando-o adequado para sinais de alta frequência.

- Espessura do Cobre: A espessura adequada do cobre é essencial para manter a integridade do sinal e minimizar perdas.

- Acabamento superficial: Immersion Silver fornece uma superfície lisa e condutora para componente anexo.

Princípio de funcionamento

O Cavity PCB opera com base no princípio de impedância controlada e perda mínima de sinal. A estrutura da cavidade permite controle preciso sobre o roteamento do sinal, reduzindo a interferência e melhorando o desempenho geral. O material Teflon F4MB garante que os sinais mantenham sua integridade à medida que passam pela placa, resultando em uma operação eficiente e confiável.

Aplicações

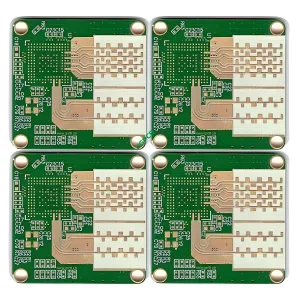

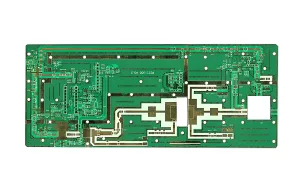

PCBs de cavidade são particularmente adequados para aplicações que exigem distribuição precisa de sinal, como divisores de energia em sistemas de comunicação. Eles também são usados em sistemas de radar, Comunicações de satélite, e outros dispositivos eletrônicos de alta frequência onde a pureza e a confiabilidade do sinal são fundamentais.

Classificação

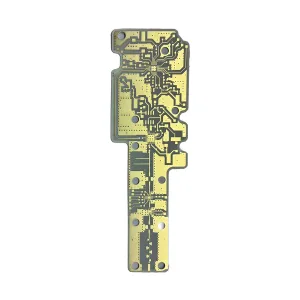

PCBs de cavidade podem ser classificados com base em sua contagem de camadas, configuração da cavidade, e aplicações específicas. As classificações comuns incluem:

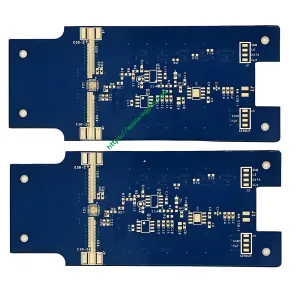

- Placas de camada única e multicamadas: Dependendo da complexidade do circuito.

- Cavidades Padrão e Personalizadas: Com base nos requisitos específicos da aplicação.

- Placas específicas de alta frequência: Projetado para aplicações específicas de alta frequência, muitas vezes com rigorosos material e padrões de fabricação.

Propriedades do material

As principais propriedades do Teflon F4MB, o material usado em PCBs de cavidade, incluir:

- Constante dielétrica baixa: Garante atraso e perda mínimos de sinal.

- Desempenho estável em faixas de temperatura: Mantém um desempenho consistente em diversas condições ambientais.

- Alta resistência à absorção de umidade: Evita a degradação da qualidade do sinal devido à entrada de umidade.

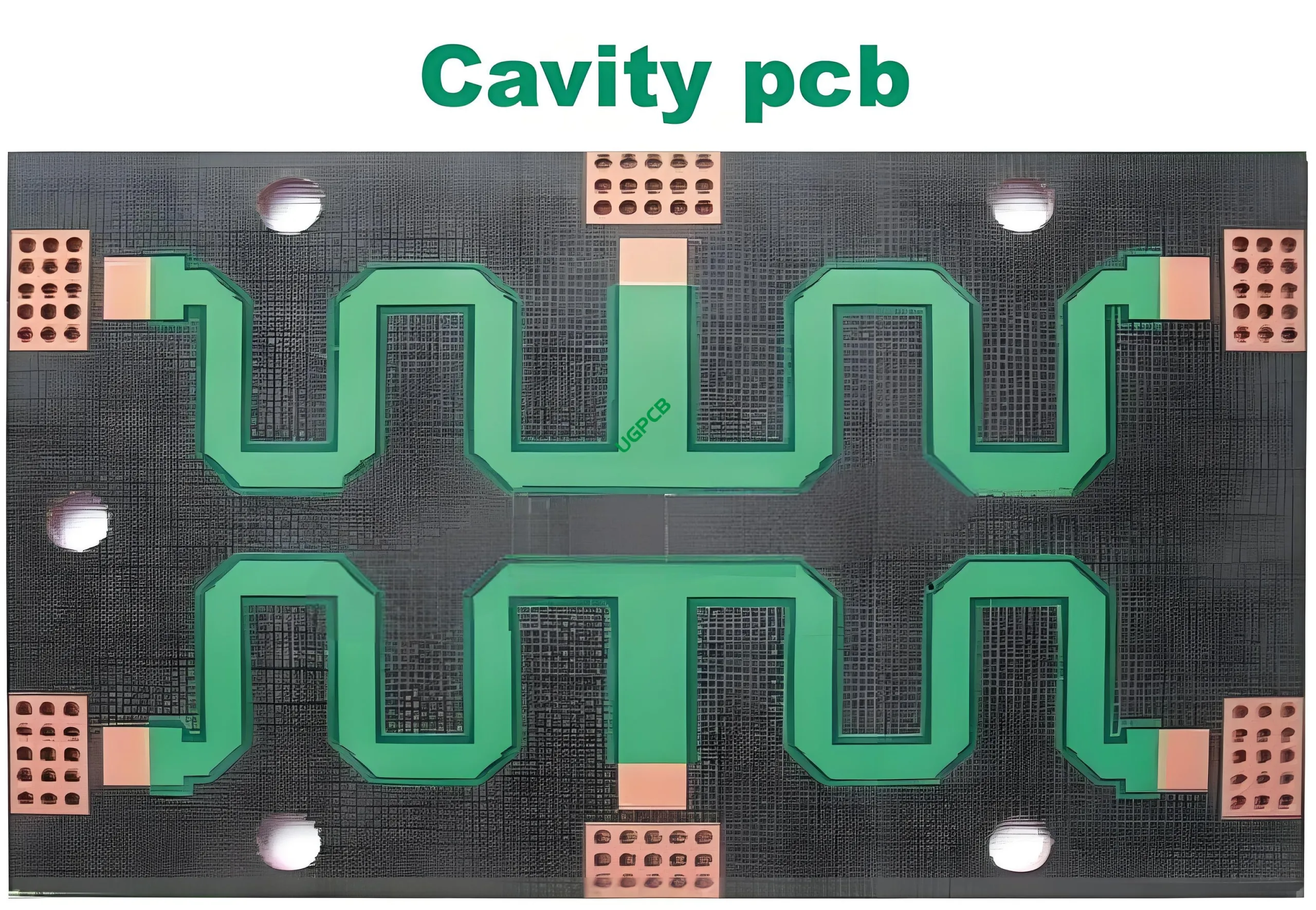

Processo de Produção

A produção de PCBs de cavidade envolve várias etapas:

- Seleção de material: Escolhendo Teflon F4MB por suas propriedades dielétricas.

- Projeto de circuito: Criando o layout do circuito com considerações para a estrutura da cavidade.

- Gravura: Remoção de cobre desnecessário para criar o padrão de circuito desejado.

- Formação de cavidade: Usinagem de precisão para criar a cavidade no material dielétrico.

- Laminação: Unindo várias camadas sob alta pressão e temperatura.

- Acabamento superficial: Aplicação de prata de imersão para melhor soldabilidade.

- Testes e controle de qualidade: Garantir que o produto final atenda a todas as especificações e padrões.

Use cenários

PCBs de cavidade são usados em cenários onde a distribuição precisa do sinal é crítica, como:

- Divisores de poder: Garantir distribuição igual de sinais em sistemas de comunicação.

- Sistemas de radar: Fornecendo recursos precisos e estáveis de processamento de sinal.

- Comunicações de satélite: Permitindo transferência confiável de dados entre a Terra e o espaço.

Resumindo, Cavity PCBs são placas de circuito especializadas projetadas para aplicações de alta frequência e micro-ondas. Sua estrutura de cavidade única, combinado com as propriedades do Teflon F4MB, os torna ideais para uso em divisores de potência e outras aplicações de distribuição de sinal de precisão.

LOGOTIPO UGPCB

LOGOTIPO UGPCB