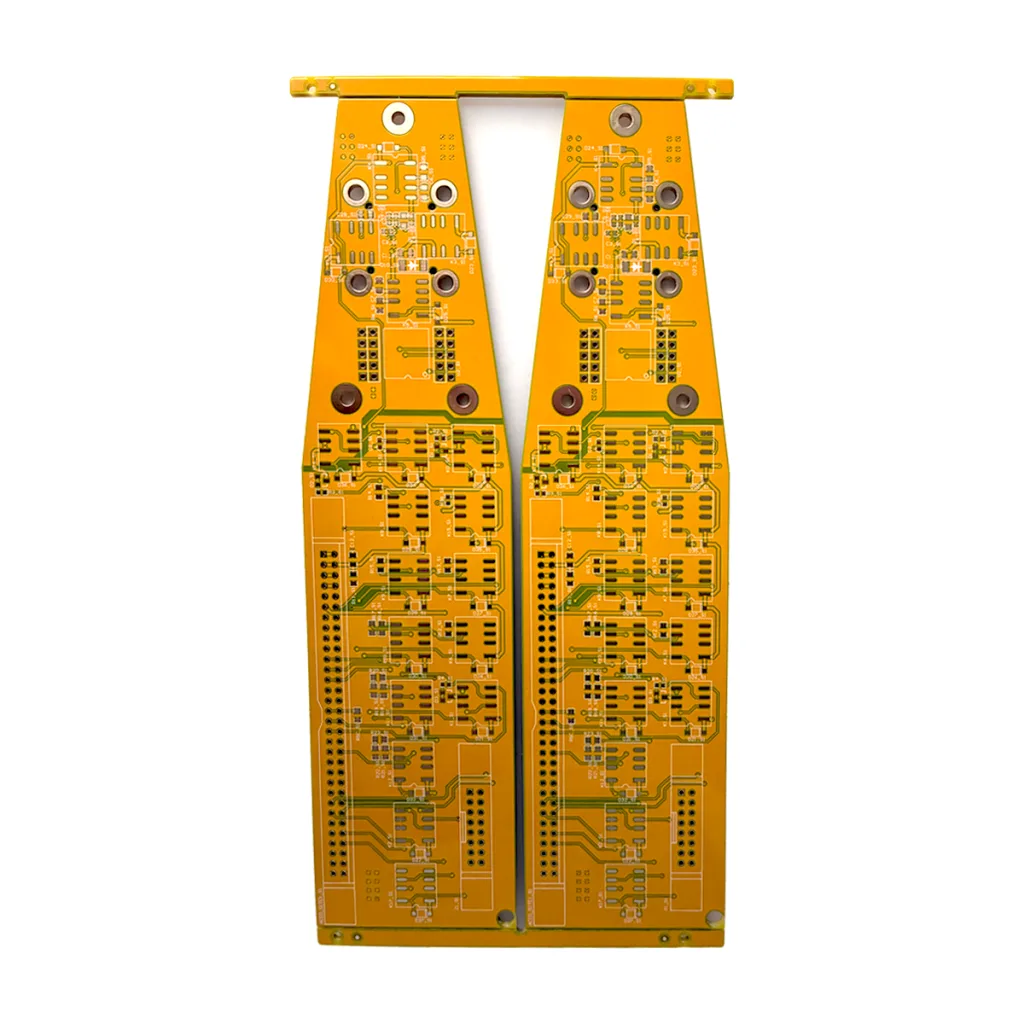

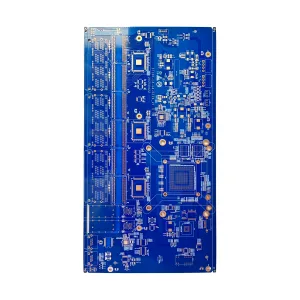

Heavy Copper PCB Overview

The Heavy Copper PCB is a specialized type of แผงวงจรพิมพ์ designed to handle high current applications. It features an increased copper thickness compared to PCB มาตรฐาน, making it ideal for power-intensive electronics. Below is a detailed introduction to this advanced พีซีบี เทคโนโลยี.

การจำแนกประเภท

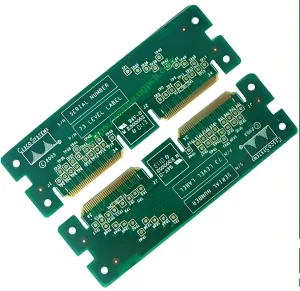

Heavy Copper PCBs are primarily classified based on their copper thickness. Common classifications include 2OZ, 3ออนซ์, 4ออนซ์, up to 6OZ (or 70um and above). รุ่นที่นำเสนอที่นี่, Heavy Copper PCB, offers copper thicknesses of 2OZ and 6OZ, tailored to meet various high-power requirements.

องค์ประกอบของวัสดุ

The Heavy Copper PCB utilizes SY S1141 as its base material, a high-quality substrate known for its electrical and mechanical properties. The PCB is constructed with 6 ชั้น, ensuring robust performance and reliability.

ลักษณะประสิทธิภาพ

Heavy Copper PCBs excel in handling high currents due to their thick copper layers. They also offer excellent thermal conductivity, which helps in dissipating heat efficiently. The surface technology used, ทองแช่ (1-3คุณ), provides a protective coating that enhances corrosion resistance and improves solderability.

การออกแบบโครงสร้าง

ตามโครงสร้าง, the Heavy Copper PCB features a board thickness of 2.8mm, providing a sturdy base for ส่วนประกอบ. The green solder mask color not only enhances visual appeal but also provides insulation and protection against environmental factors. The white silk screen adds to the board’s readability by clearly marking component locations and other essential information.

คุณสมบัติที่โดดเด่น

The defining feature of Heavy Copper PCBs is their ability to carry high currents without overheating or experiencing excessive voltage drop. This is achieved through the use of thick copper layers, which also contribute to the board’s overall durability. นอกจากนี้, the immersion gold surface finish ensures long-term reliability and ease of soldering.

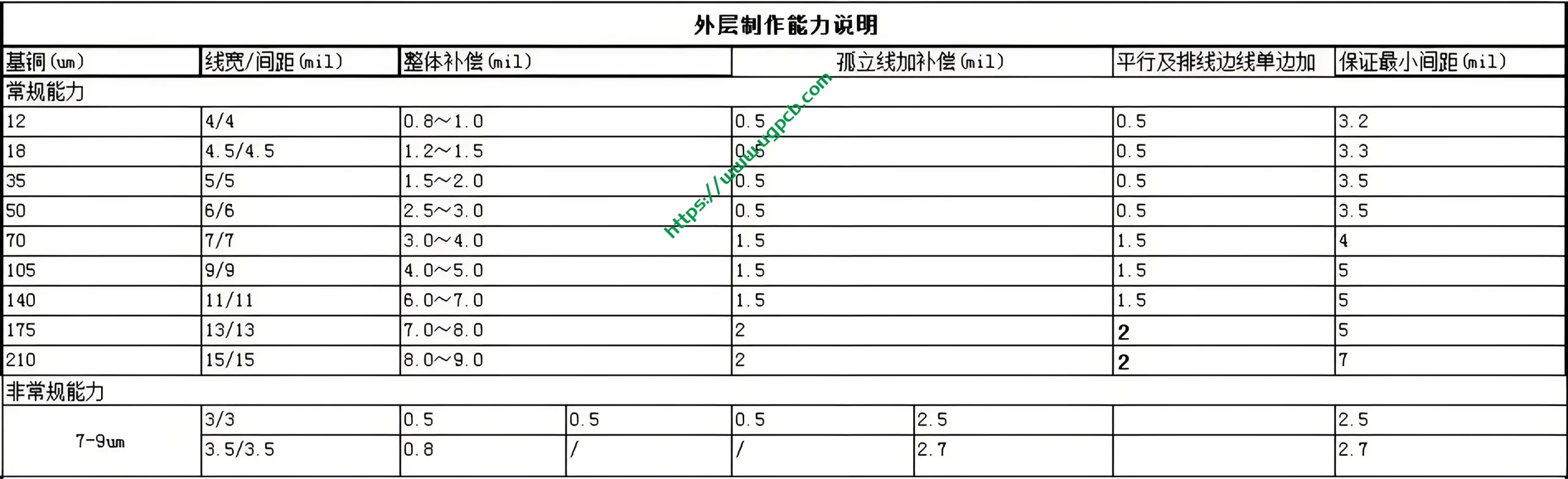

กระบวนการผลิต

The production of Heavy Copper PCBs involves several precision steps:

- Base Material Preparation: The SY S1141 substrate is prepared and cut to size.

- การเคลือบทองแดง: Thick copper foil is laminated to the substrate using advanced bonding techniques.

- รูปแบบวงจร: The desired circuit patterns are etched onto the copper foil.

- การซ้อนชั้นและการเคลือบ: Multiple layers are stacked and laminated together to form the final PCB structure.

- การเจาะและการชุบ: Holes are drilled for component mounting and interconnection, followed by plating to enhance conductivity.

- Soldermask Application: A green soldermask is applied to protect the circuits and provide insulation.

- Silk Screen Printing: White silk screen ink is used to print component labels and other markings.

- การประยุกต์ใช้การตกแต่งพื้นผิว: The immersion gold coating is applied to the PCB surface.

- การตรวจสอบและทดสอบขั้นสุดท้าย: The PCB undergoes rigorous inspection and testing to ensure quality and performance.

สถานการณ์การใช้งาน

Heavy Copper PCBs are widely used in power converter applications due to their ability to handle high currents and dissipate heat efficiently. They are also suitable for other high-power electronics, such as inverters, motor controllers, and battery management systems. ในแอปพลิเคชันเหล่านี้, Heavy Copper PCBs ensure reliable performance and extended product lifespan.

โลโก้ UGPCB

โลโก้ UGPCB