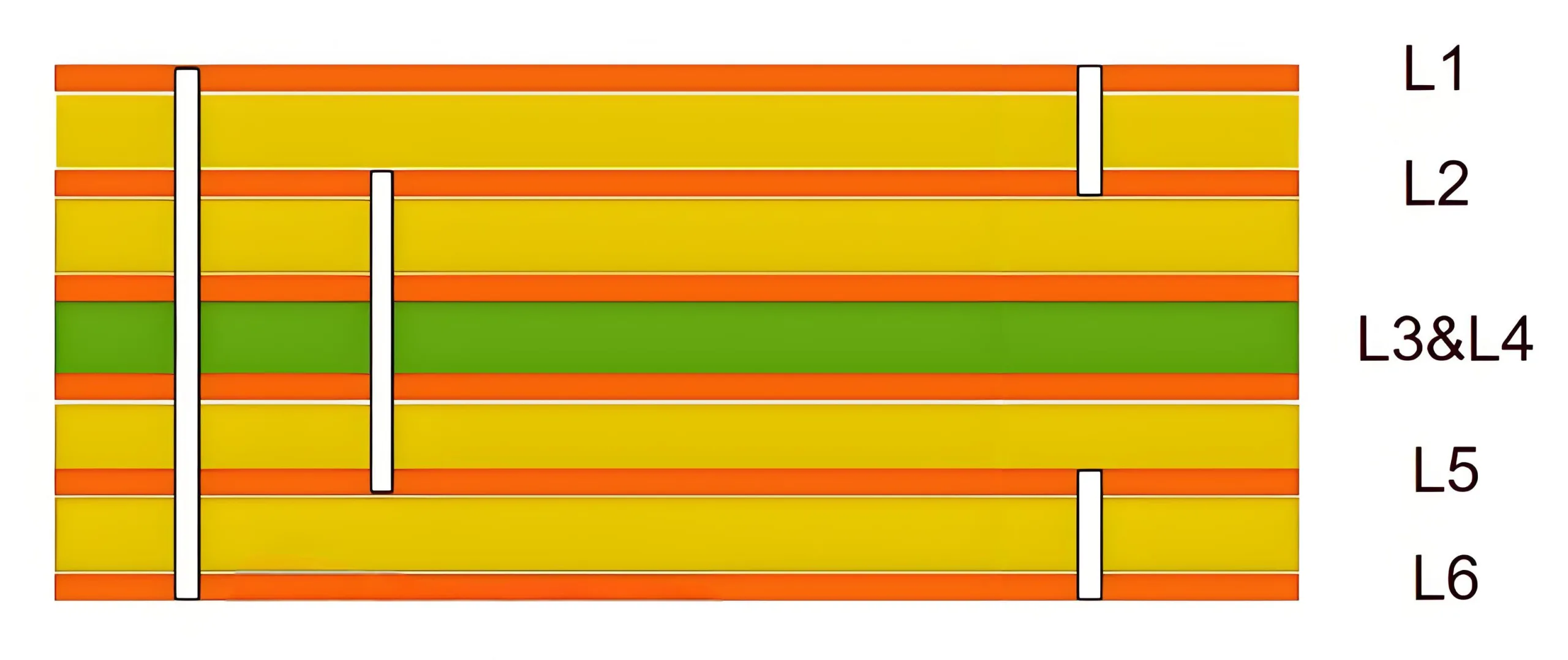

What is a 6L 1+N+1 HDI PCB?

A 6L 1+N+1 HDI PCB stands for a six-layer High Density Interconnect (IDH) placa de circuito impreso, featuring one core layer flanked by N signal layers and another core layer. This configuration allows for high density interconnections, making it suitable for advanced electronic applications. El “1+N+1” designation refers to the arrangement of the core layers and signal layers.

Requisitos de diseño

The design of a 6L 1+N+1 HDI PCB requires careful consideration of several factors:

- Apilamiento de capas: Proper alignment of the core and signal layers to ensure optimal electrical performance.

- Trace and Space: Minimal trace width and space of 3mil/3mil to accommodate fine features.

- Hole Sizes: Mechanical holes as small as 0.2mm and laser holes down to 0.1mm for precise component placement.

- Espesor de cobre: Varied copper thickness with inner layers at 1OZ and outer layers at 0.5OZ to balance conductivity and flexibility.

¿Cómo funciona??

The functionality of a 6L 1+N+1 PCB HDI relies on its multilayer structure and the use of high-density interconnects. Each layer serves a specific purpose:

- Core Layers: Provide structural integrity and act as the foundation for signal layers.

- Capas de señal: Carry electrical signals between components.

- Tratamiento de superficie de oro de inmersión: Ensures excellent solderability and long-term reliability by preventing oxidation.

Aplicaciones y clasificaciones

Estos PCB are primarily used in intelligent digital products where compact size and high performance are crucial. They can be classified based on their complexity and the number of layers, with the 6L 1+N+1 configuration being highly versatile for various applications.

Materiales y rendimiento

Constructed from FR-4 (ITEQ), these PCBs offer excellent thermal stability and mechanical strength. The green/white color scheme aids in visual inspection and troubleshooting. The finished thickness of 1.0mm provides a robust yet flexible board suitable for intricate designs.

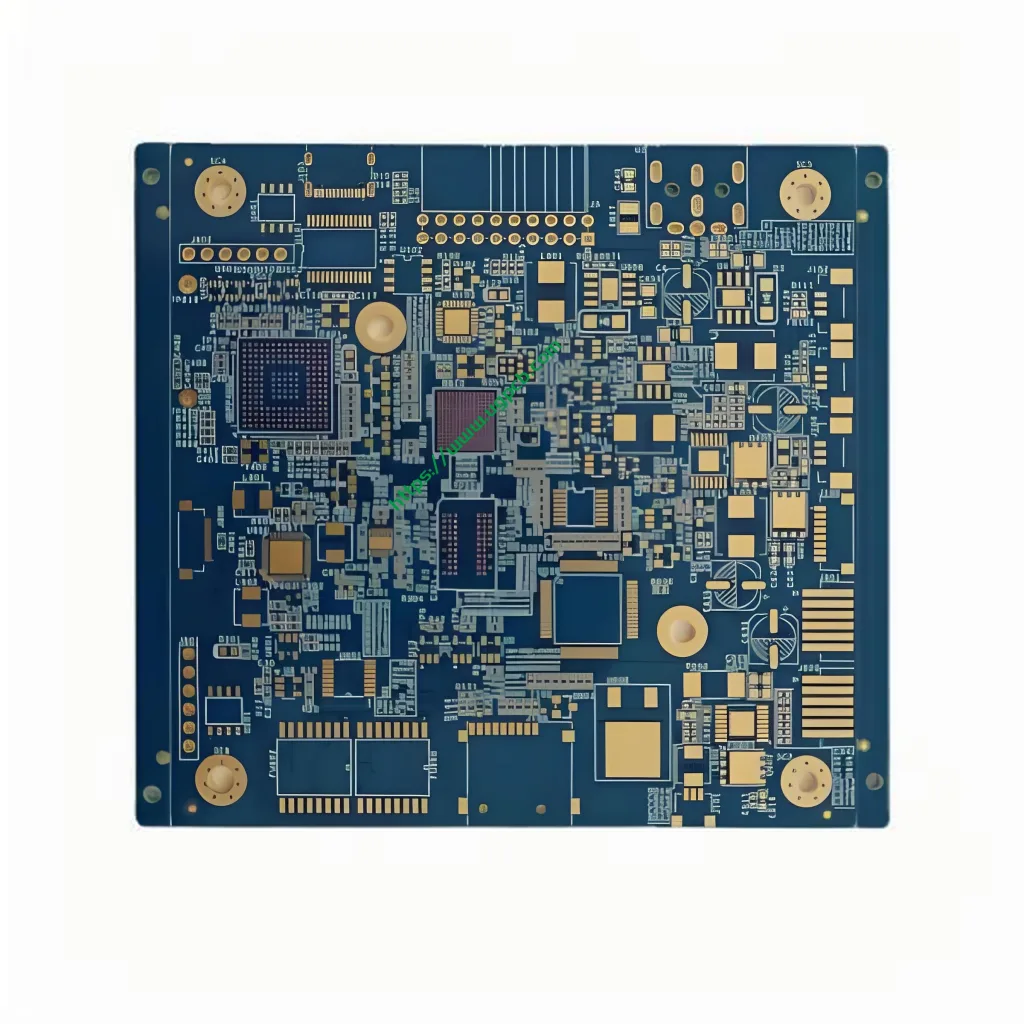

Estructura y características

The unique structure of a 6L 1+N+1 HDI PCB includes:

- Six Layers: One core layer, N signal layers, and another core layer.

- High Density Interconnects: Allow for complex routing and minimal space usage.

- Superficie de inmersión en oro: Enhances conductivity and protects against corrosion.

Proceso de producción

The manufacturing process involves several sophisticated steps:

- Preparación de material: Selecting high-quality FR-4 substrate and copper foils.

- Apilamiento de capas: Arranging the layers in a precise order to achieve the desired “1+N+1” configuration.

- Vinculación: Usar calor y presión para unir las capas..

- Aguafuerte: Aplicar grabador para eliminar el exceso de cobre., dejando sólo los caminos conductores deseados.

- Enchapado: Adding a thin layer of metal to improve conductivity and solderability.

- Tratamiento superficial: Applying immersion gold to protect against oxidation and enhance solderability.

- Control de calidad: Realizar inspecciones y pruebas exhaustivas para garantizar que cada placa cumpla con estrictos estándares de calidad..

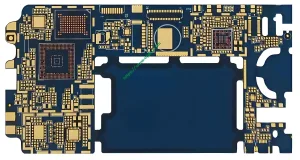

Casos de uso y escenarios

6L 1+N+1 HDI PCBs are ideal for use in intelligent digital products where miniaturization and high performance are critical. Las aplicaciones comunes incluyen:

- Teléfonos inteligentes: Permitir diseños más delgados sin comprometer la funcionalidad o el rendimiento.

- Tabletas: Proporcionar conectividad confiable para la transferencia y el procesamiento de datos de alta velocidad.

- Dispositivos portátiles: Admite diseños compactos y mantiene un rendimiento y una durabilidad sólidos.

UGPCB LOGO

UGPCB LOGO