무선 신호는 보이지 않는 공기파를 가로 지 릅니다, 구동 RF PCB 침묵하면서도 변혁적인 기술 진화를 겪고 있습니다.

고주파 통신의 빠른 발전은 RF PCB 기술을 새로운 시대로 추진하는 것입니다.. 글로벌 5G 인프라 배포가 가속화됩니다, 밀리미터 파 스펙트럼 채택이 확장됩니다, IoT 장치 증식은 기하 급수적으로 증가합니다. RF 회로에서 전례없는 성능을 요구합니다..

전통적인 FR-4 재료는 고주파 요구 사항으로 어려움을 겪고 있습니다, 그래 핀 트랜지스터와 같은 혁신, 액정 중합체 (LCP) 기판, 저온 경화 접착제는 물리적 경계를 밀고 있습니다. 동시에, 리지드 플렉스 PCB 이제 달성하십시오 100,000+ 굽힘주기, 유연한 회로의 두께는 0.05mm에 이릅니다, 커스텀 길이의 FPC 생산이 실현 가능해집니다-웨어러블 전자 제품 및 새로운 에너지 차량 혁신을 가능하게하는 제조 혁신.

1. 물질 혁명: 고주파 장벽을 깨는 것

RF PCB 성능은 핵심 재료 특성에 달려 있습니다. 밀리미터 파 주파수에서 (>30GHz), 유전 상수 (DK) 그리고 소산 인자 (Df) 신호 전송 효율을 결정하는 중요한 선택 파라미터가됩니다.

전통적인 FR-4 (dk 음 4.3, df≈0.02) 10GHz 이상의 상당한 손실을 나타냅니다, 5G/레이더 요구에 실패합니다. 업계 솔루션에는 현재 포함됩니다:

-

그래 핀 RF 트랜지스터: 유연한 기판은 이제 39GHz 컷오프 주파수 장치를 지원합니다. 캐리어 이동성은 도달합니다 2,500 cm²/v · s <10% 이후의 성능 저하 1,000 굽힘주기 (IEC 60340 기준).

-

LCP 기판: 웨어러블을 선호합니다, LCP 하이브리드 플렉스 회로가 달성됩니다 >90% 100,000 배 내구성을 갖는 투과율 및 3mm 굽힘 반경. 우수한 전기 특성 (DK = 2.9-3.1, DF = 0.002-0.004) 기존의 재료를 능가합니다.

-

낮은 팁 접착제: 새로운 에폭시 제형은 80-120 ℃에서 치료한다 (30% 전통적인 프로세스보다 낮습니다), 스텐실 라이프를 연장합니다 8,000+ 생산 비용을 줄이면서 인쇄 18%. 미니 LED 포장 및 자동차 플렉스 회로에 이상적입니다.

고주파 PCB 재료 비교

| 재료 | DK | Df | 최대 주파수 | 비용 요인 |

|---|---|---|---|---|

| 표준 FR-4 | 4.3-4.8 | 0.018-0.025 | <5GHz | 1.0엑스 |

| 로저스 4350B | 3.48± 0.05 | 0.0037 | 30GHz | 8.5엑스 |

| PTFE 기반 | 2.8-3.0 | 0.0009-0.002 | 77GHz | 12엑스 |

| LCP | 2.9-3.1 | 0.002-0.004 | 110GHz | 15엑스 |

| 그래 핀 복합재 | 2.3-3.5 | 0.0005-0.001 | >100GHz | 20x+ |

2. 디자인 혁신: 재정의 밀도 & 능률

장치 소형화는 공간 최적화를 요구합니다 RF PCB 디자인:

-

초박형 플렉스 회로 (0.05mm) 배선 밀도를 증가시킵니다 50%, 활성화 20% 테슬라의 부피 감소 4680 배터리 팩.

-

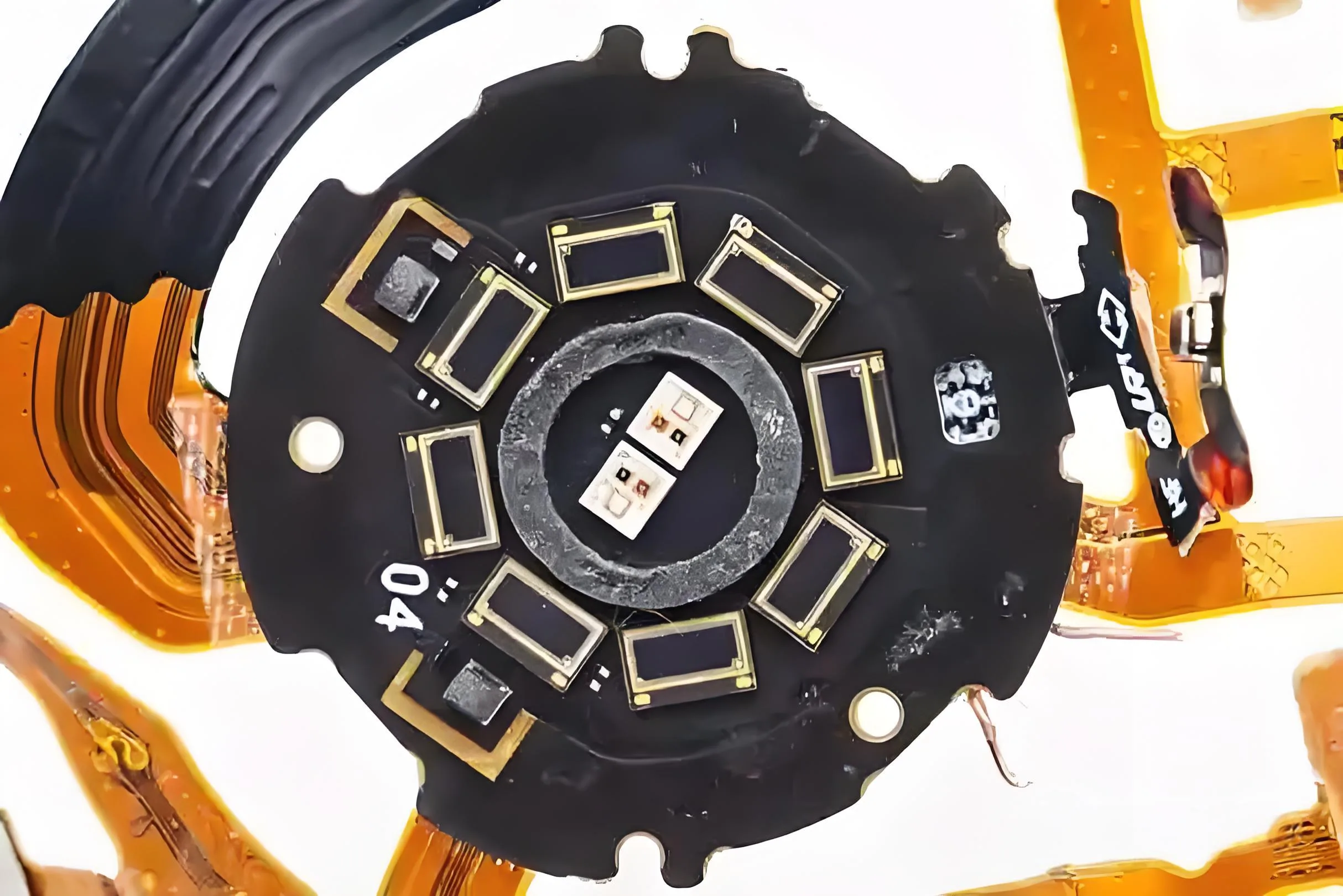

HDI Ridid-Flex 보드는 56Gbps 처리량으로 20/20μm 트레이스/공간을 달성합니다 (예를 들어, Apple Vision Pro 시안 추적 센서), 스터브를 제어하기 위해 레이저 백 링을 사용합니다 <50μm.

-

열 관리 혁신: 나노 수정 된 폴리이 미드는 800V EV 플랫폼의 300 ° C 및 1200V 분해 전압을 견딜 수 있습니다..

*”스마트 워치 곡선에 대한 Rigid-Flex PCBS 윤곽, 우주 활용 개선 40%” - 화웨이 시계 GT4 디자인 팀*

3. 조작: 정밀도는 지능을 충족합니다

-

레이저 직접 이미징 (LDI): 5μm 선 너비를 활성화합니다 92% 생산하다, 3 배의 전통적인 노출 효율.

-

단계적 처리: ± 2μm 치수 정확도를 위해 레이저 에칭과 다이 커팅을 결합합니다 (01005 구성 요소 호환).

-

AI 육안 검사: 99.9% 미크론 수준의 결함에 대한 결함 인식, 비용을 절감하면서 신뢰성 향상.

4. 응용: 전기 자동차에 웨어러블

웨어러블 기술

Rigid-Flex PCB는 $ 150B 웨어러블 시장을 지배합니다:

-

압력 감지 플렉스 PCB가있는 lululemon 요가 바지

-

Apple Watch 울트라 ECG 연결 (500MBPS 데이터 속도)

-

메타 퀘스트 4 HDI 보드 통합 12 카메라 + 5 MMWAVE 레이더

EV 전자 장치

Byd의 자동차 플렉스 솔루션:

-

100K 셀 모니터링/SEC를 갖는 BMS FPC

-

스티어링 휠 ECG 모듈 (95% 정확성)

-

6G V2X에 대한 THZ- 준비 회로 (0.1MS 대기 시간 대상)

고주파 시스템

그래 핀 RF 트랜지스터는 39GHz 5G/6G 기지국을 활성화합니다. 전도성 잉크는 피부 효과를 줄입니다, 그래 핀-코퍼 복합재는 부식성을 향상시킵니다.

5. 미래의 트렌드: 수렴 & 진보

-

임베디드 구성 요소 (IPD): 01005 구성 요소 통합은 보드 크기를 줄입니다 40% 신호 무결성을 향상시키는 동안.

-

자체 강력한 시스템: 트리 보전 나노 제너레이터 (Teng) 운동 에너지를 수확하십시오; Neuralink 스타일의 뇌 인터페이스는 사고 제어 차량을 가능하게합니다.

-

지속 가능한 제조: 수성 잉크와 무연 납땜은 폐기물을 줄입니다 40%. 구리 재활용 속도 >95% 지원하다 “카본 FPC” 의 목표 2030.

*재료 과학자들이 예측합니다: “그래 핀-액체 금속 복합재는 6g 물리 층의 100GHz 장벽을 위반할 것이다.”*

6. 결론

RF PCB 진보는 재료에 걸쳐 있습니다 (그래 핀/LCP), 설계 (3D 통합), 그리고 제조 (AI/LDI). 이러한 혁신은 5G 인프라를 유도합니다, 웨어러블 기기, 및 EV 성능.

5G/mmwave 배포 및 IoT 성장이 확장됩니다, 수요 고주파 PCB 공급 업체 강화됩니다. 업계 리더는 좋아합니다 UGPCB 고급 재료 및 유연한 회로 기술에서 특허받은 솔루션을 계속 개발.

UGPCB 로고

UGPCB 로고