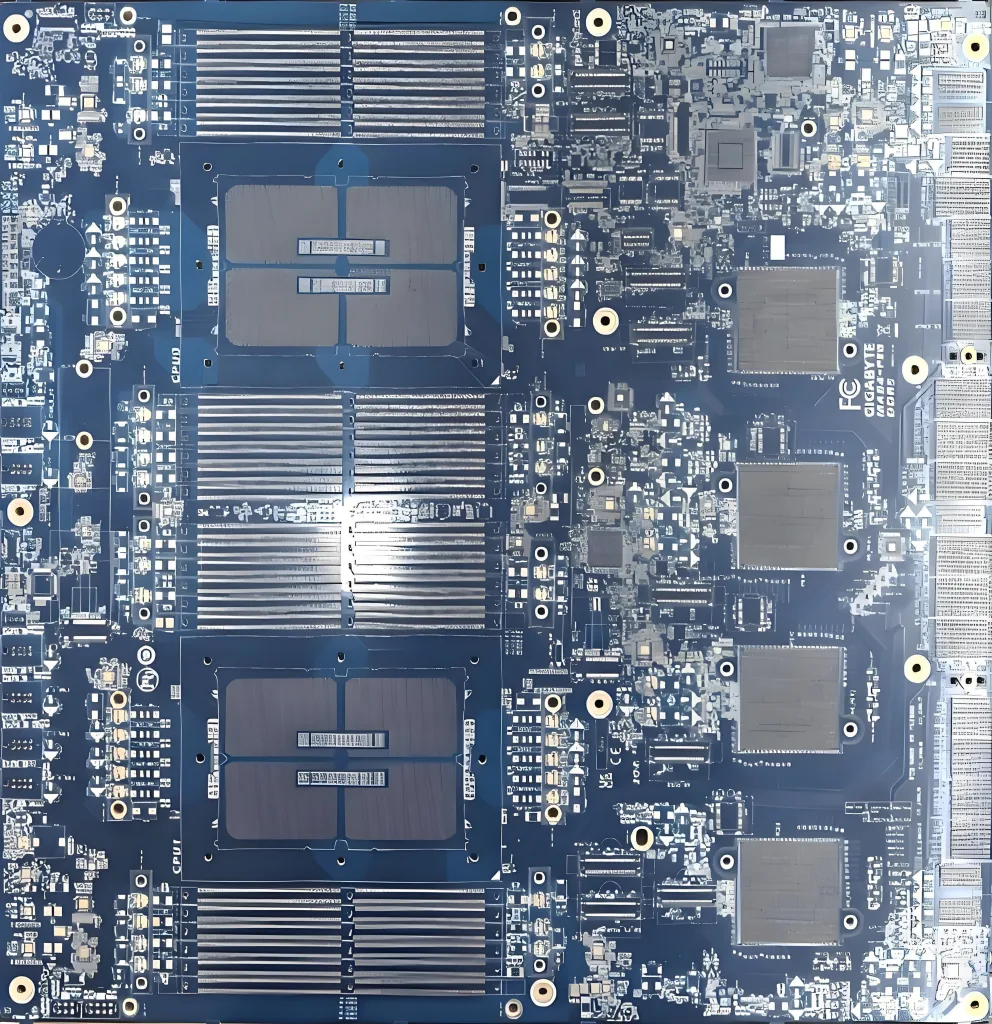

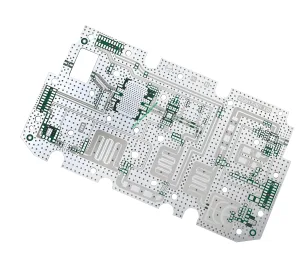

UGPCB 26-Layer High-Performance Server PCB: The Core Foundation for Data Center Computing Power

In the digital era, servers are the “super-brains” processing massive data, 그리고 섬기는 사람 PCB (인쇄 회로 기판) is the critical “신경망” of this brain. A well-designed, precisely manufactured high-end server motherboard PCB directly determines a data center’s processing speed, power efficiency, and long-term operational stability. 심층적인 전문 지식을 활용하여 고속, 고층 카운트 PCB 제조, UGPCB has developed this flagship 26-layer server PCB for next-generation High-Performance Computing (HPC), AI 서버, and cloud data centers. It is engineered to deliver exceptional electrical performance and reliable physical structure to support extreme computational loads.

제품 정의 & 개요: What is a High-End Server PCB?

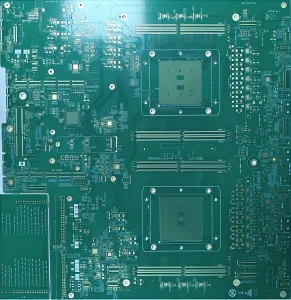

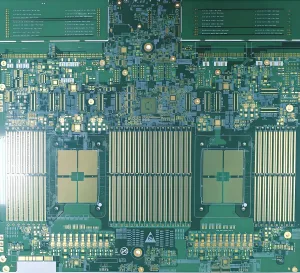

A high-end server PCB is a complex, multi-layer circuit board designed to host core components like CPUs, 메모리, high-speed interfaces (예를 들어, PCIE, CXL), and power management units, and to establish ultra-high-speed, highly reliable electrical connections between them. It is not just a mechanical substrate but a critical platform for ensuring signal integrity and power integrity at GHz frequencies. 이것 UGPCB product features a sophisticated 26-layer PCB stack-up, utilizing advanced materials and processes specifically engineered for demanding applications like big data processing and AI training.

Core Design Points & 작동 원리

The primary function of a server PCB is to provide a low-loss, low-interference transmission path for high-speed digital signals and high-current power delivery. Its design revolves around several key principles:

-

신호 무결성 (그리고): The use of 고속 재료 (Tg 170) and precise control over trace width/spacing of 0.08mm/0.09mm minimizes signal attenuation and distortion, ensuring error-free data transmission at rates of tens of Gb/s.

-

전력 무결성 (PI): The incorporation of 2oz heavy copper (2/2 온스) for power and internal planes reduces DC resistance and temperature rise, delivering ample and clean power to high-power chips like CPUs/GPUs.

-

임피던스 제어 & 백드릴링: Strict impedance control is applied to high-speed channels. A key innovation is the use of backdrilling technology to remove the unused conductive stub (barrel) of plated through-holes, eliminating signal reflection points—a core process for enhancing signal quality in 고속 PCB.

-

열 관리 & 신뢰할 수 있음: 에이 finished board thickness of 2.97mm ±10% 그리고 높은 Tg 170 재료 provide excellent mechanical strength and heat resistance, ensuring the PCB remains stable and reliable under the prolonged, 고온, full-load operation of servers.

기술 사양 & 재료

-

레이어 수 & 두께: 26 레이어, finished board thickness 2.97mm ±10%.

-

Copper Weight Stack-up: Complex configuration: 1/1/H/1/H/1/H/1/H/1/H/2//2/2/H/1/H/1/H/1/H/1/H/1/1 oz. Critical power layers use 2oz heavy copper to balance signal and power needs.

-

핵심 자료: Taiyao TU883 고속, low-loss laminate 와 유리전이온도 (Tg) of 170°C. It offers a very low dielectric constant (DK) and dissipation factor (Df), making it a top-tier choice for high-speed PCB materials.

-

선 정밀도: Minimum trace width/space of 0.08mm / 0.09mm, enabling high-density routing.

-

Micro-Via Technology: Supports a minimum mechanical drill diameter of 0.20mm, meeting high-density interconnection (HDI) 요구 사항.

-

표면 마감: 유기 용해성 보존 (OSP) 아파트를 제공합니다, highly solderable surface for high-performance BGA and chip 구성 요소, offering excellent cost-effectiveness.

제품 분류, 구조 & 특징

-

과학적 분류: This product belongs to the category of “High-End Multi-Layer High-Speed Server Motherboard PCBs”, 구체적으로 “높은 Tg, High-Layer-Count, 백드릴링됨, Heavy-Copper Power Delivery PCBs”.

-

Core Structural Features:

-

다층 적층: Precise arrangement of signal, 지면, and power planes creates effective electromagnetic shielding and low-impedance return paths.

-

Backdrill Structure: Through-holes for critical high-speed links (예를 들어, PCIe lanes, memory slot connections) are backdrilled to significantly enhance high-frequency performance.

-

RTF Copper Foil Application: The use of Reverse Treated Foil provides a smoother copper surface, further reducing signal loss during transmission along the conductor.

-

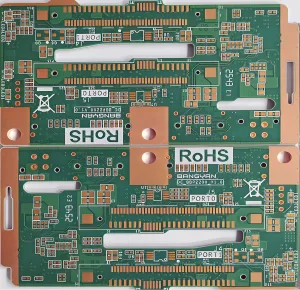

Rigorous Production Process

UGPCB’s manufacturing process strictly adheres to IPC-A-600G/6012 Class 2/3 표준, with enhanced controls for server PCBs:

Material Cutting → Inner Layer Imaging & AOI Inspection → Lamination & Drilling → Electroless & Electrolytic Copper Deposition → Backdrilling Process → Outer Layer Imaging → Secondary AOI & Impedance Testing → Solder Mask & OSP Application → Electrical Test (Flying Probe/Test Fixture) → Final Visual Inspection & 포장.

이들 중, backdrilling 그리고 임피던스 테스트 are critical control points ensuring the quality of this high-performance server PCB.

Target Applications

This product is specifically designed and manufactured for the following high-end applications:

-

인공 지능 & Machine Learning Servers: Hosting training and inference GPU/ASIC clusters.

-

클라우드 컴퓨팅 & Data Center Servers: For High-Performance Computing (HPC) clusters and virtualization hosts.

-

Enterprise Storage Servers: Storage devices requiring high reliability and numerous high-speed data interfaces.

-

5G Core Network Equipment: Network infrastructure handling high-speed data switching.

UGPCB 로고

UGPCB 로고