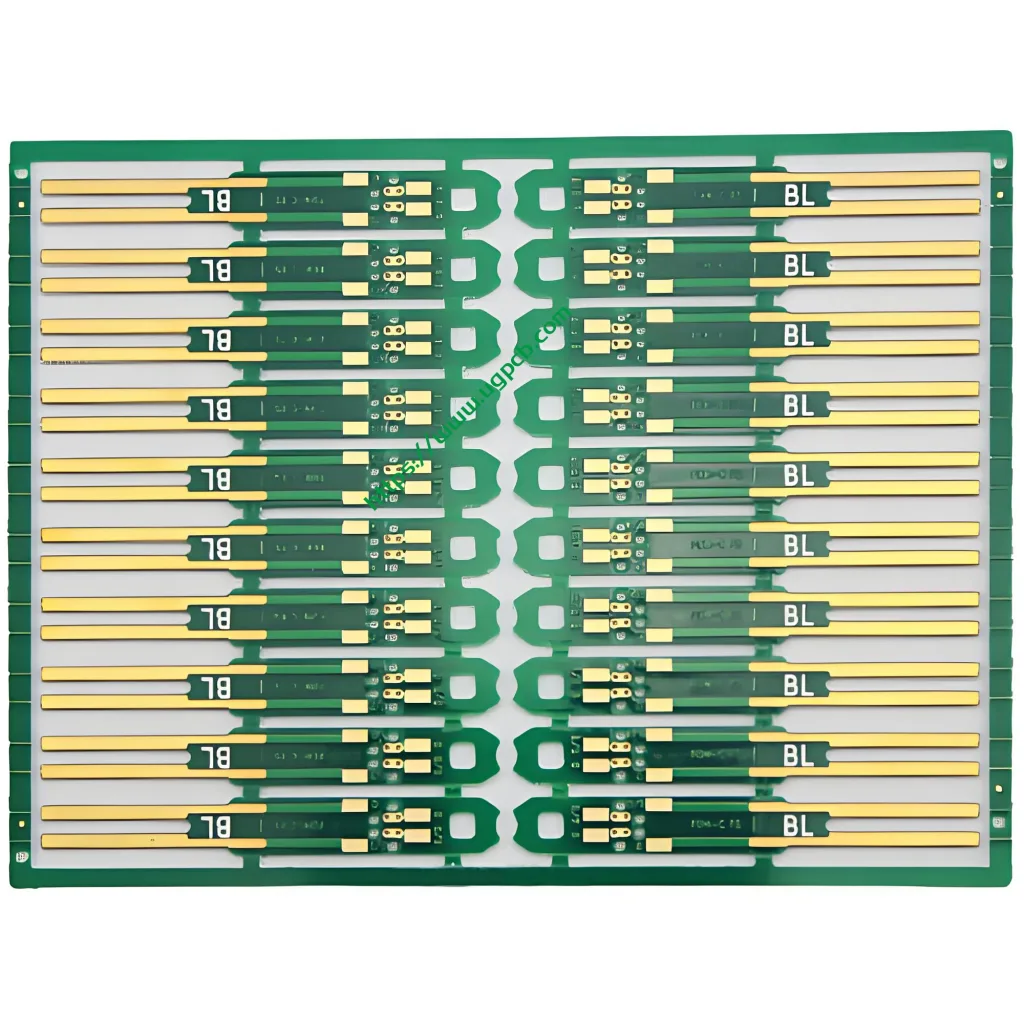

Engineered for High-Frequency RF Performance: The UGPCB 2-Layer Halogen-Free Antenna PCB Solution

In the era of IoT and high-speed wireless communication, antenna performance is paramount to device connectivity and stability. UGPCB’s 2-Layer Halogen-Free Antenna PCB is a high-performance, environmentally conscious printed circuit board solution engineered specifically for RF circuit design. It is more than a signal carrier; it is a critical component for optimizing antenna efficiency, ensuring precise impedance matching, and enhancing overall device reliability. With deep expertise in high-frequency PCB 설계, we deliver a complete PCB to PCB solution through stringent process controls and meticulous material selection.

심층 분석: From Materials to Structure

1. 제품 정의

A 2-layer halogen-free antenna PCB is a double-sided circuit board dedicated to RF antenna circuitry. Its defining characteristic is the use of an environmentally friendly substrate free from halogens (염소, 브롬). This makes it compliant with international directives like RoHS while meeting stringent RF performance requirements, making it particularly suitable for consumer electronics and export-oriented products.

2. 핵심 재료 & 전기적 특성

-

Substrate Material: Premium Halogen-Free FR-4 laminate. This material emits very low levels of toxic gases when combusted, offering enhanced safety and environmental benefits.

-

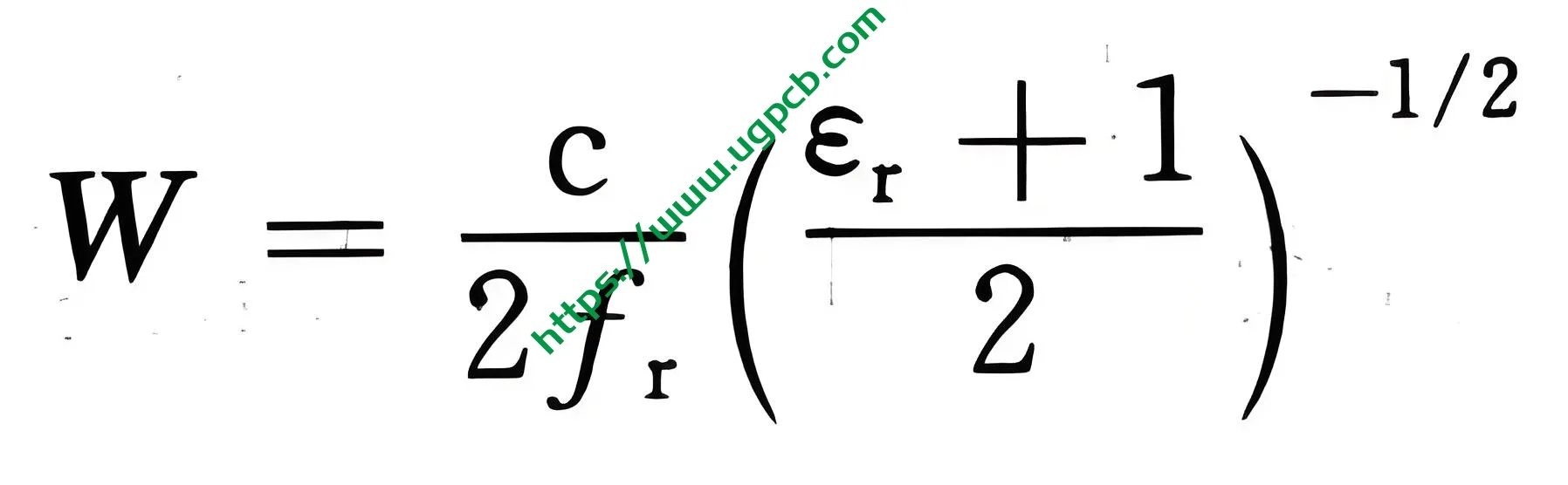

유전 상수 (DK): A stable Dk value of 4.2. This is a critical parameter for antenna PCB 설계. A stable Dk ensures consistent signal propagation velocity, forming the foundation for predictable antenna impedance control and performance.

-

구리 무게: Base copper of 0.5 온스, finished copper thickness of 1 온스 (35μm). The thickened copper layer helps reduce conductor loss and improves antenna radiation efficiency.

-

표면 마감: 이머젼 골드 (동의하다). Provides excellent solderability, superior oxidation resistance, and a flat surface for antenna contact points or solder pads, making it ideal for the PCB and SMT assembly process.

3. 구조 설계 & 주요 매개변수

-

레이어 수 & 두께: 2-layer construction with a standard finished board thickness of 0.8mm, ideal for wireless modules and compact devices.

-

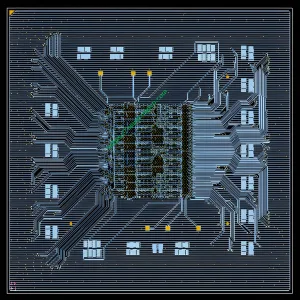

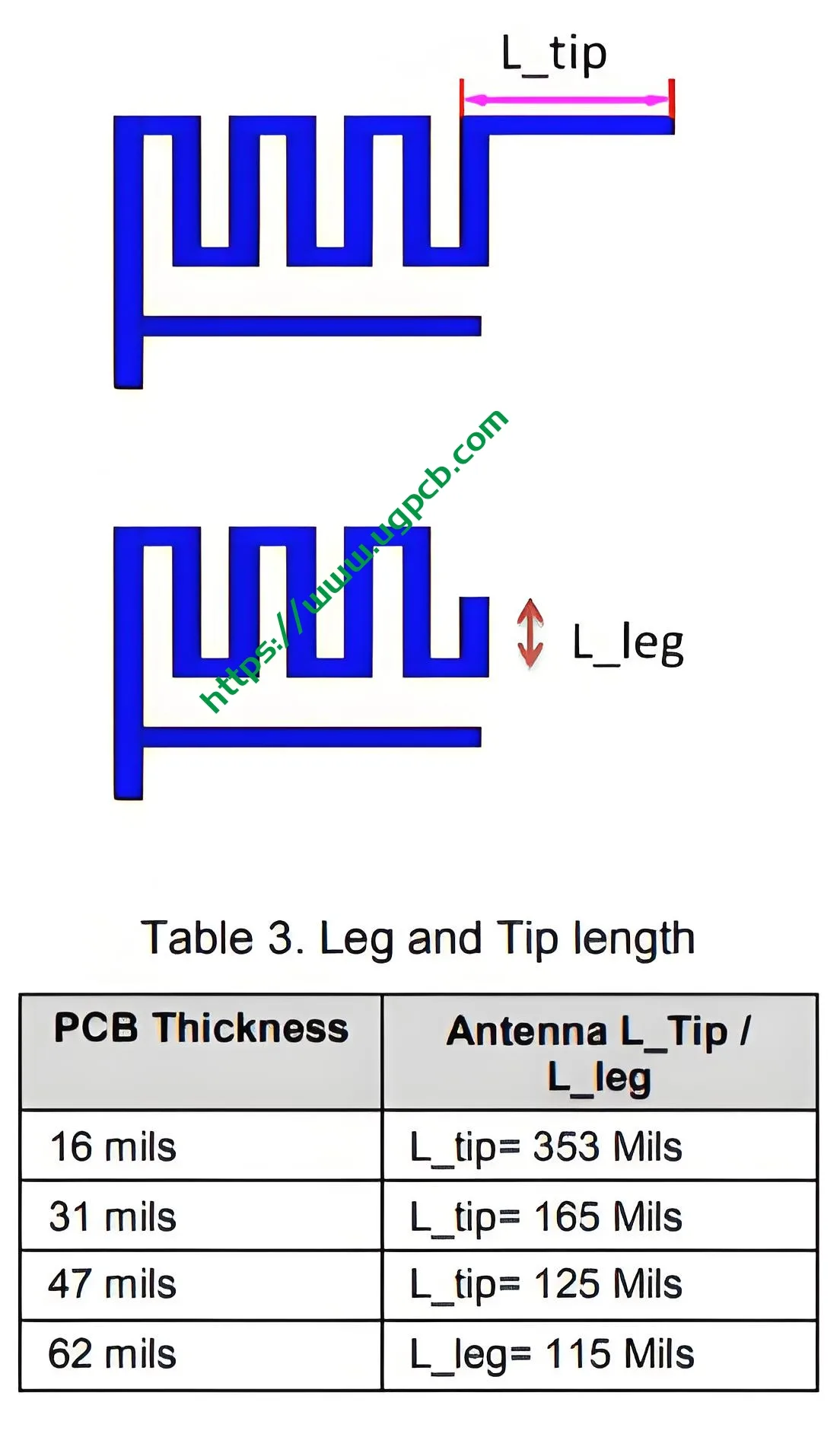

Line Precision: Minimum trace/space capability of 12mil/12mil. We maintain strict tolerances to ensure precise routing control, which is essential for accurate 50Ω microstrip transmission line design. This directly impacts antenna performance metrics like return loss and VSWR.

-

Solder Mask Options: Standard green or white solder mask. White mask is especially beneficial for laser marking and high-end product identification.

디자인 필수사항 & Operating Principle

주요 설계 고려 사항:

-

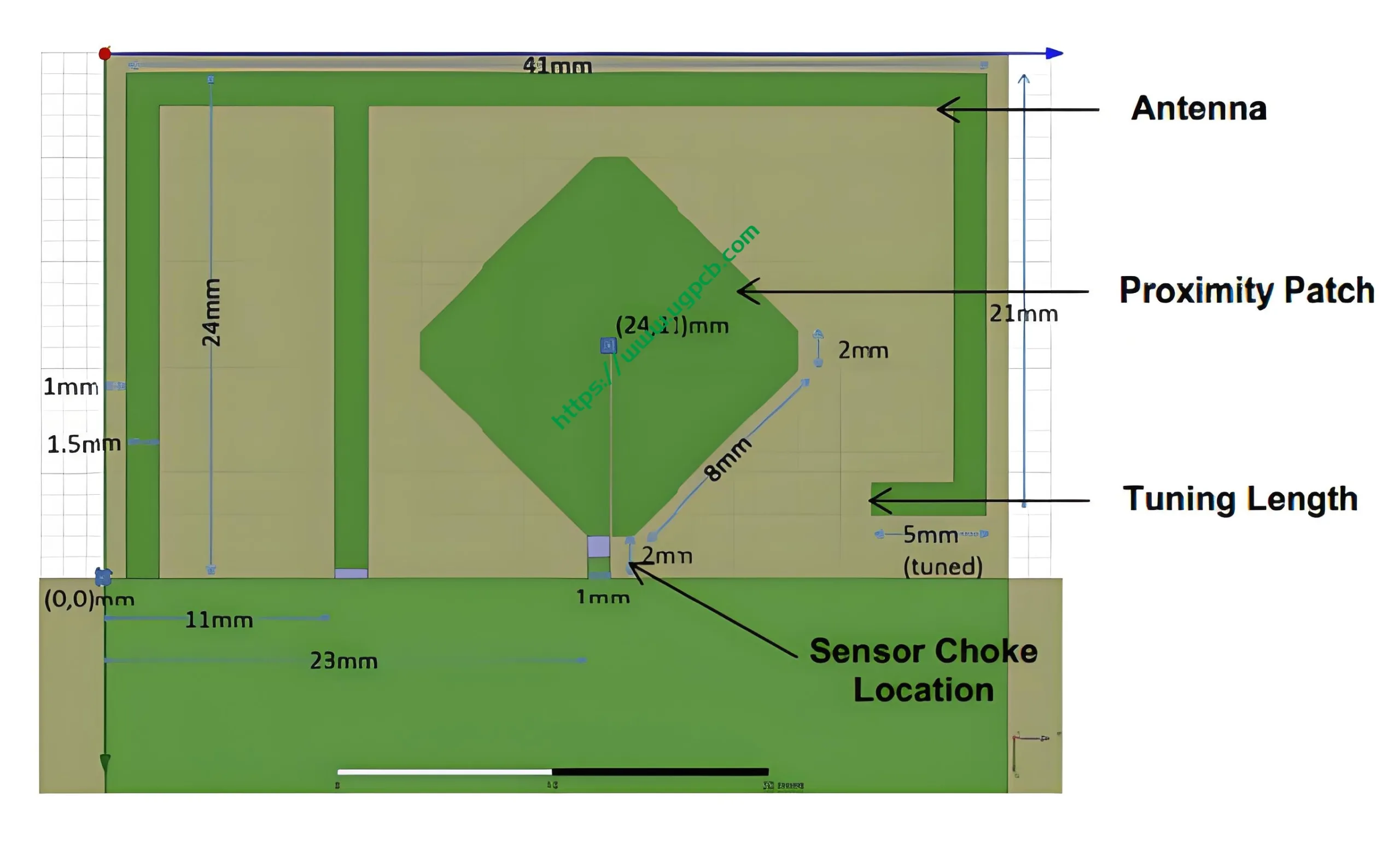

임피던스 매칭: Utilizing the stable Dk (4.2) and precise trace width control (12밀), designers can calculate or simulate exact 50Ω microstrip lines for perfect impedance matching between the antenna and the RF front-end.

-

Grounding Strategy: A well-planned ground plane (접지) provides a complete return path for RF signals, minimizing interference and radiation loss.

-

Layout Isolation: Physically and spatially isolating the antenna section from other high-speed digital circuits (예를 들어, MCU, DC-DC 변환기) to prevent noise coupling.

Operating Principle:

The copper traces on the antenna PCB are designed into specific geometries (예를 들어, Inverted-F Antenna, meander line antenna). When an RF signal travels from the chip through a matching network to the antenna, these traces convert the electrical signal into electromagnetic waves for radiation (transmit mode) or convert incoming electromagnetic waves into electrical signals (receive mode). The efficiency of this process is highly dependent on the dielectric stability of the PCB laminate and the precision of the trace fabrication.

특징 & 장점

-

Stable High-Frequency RF Performance: Consistent Dk (4.2) and strict trace tolerances ensure reliable, repeatable antenna performance across production batches.

-

Eco-Friendly & 믿을 수 있는: Halogen-free materials meet green manufacturing standards, enhancing product safety and market accessibility.

-

High-Process Quality: ENIG surface finish offers oxidation resistance and long shelf life, providing perfect pads for subsequent SMT assembly and PCBA 프로세스.

-

Expert Design Support: UGPCB offers PCB 설계 검토 services to help customers optimize antenna layout and stack-up, avoiding common RF design pitfalls.

-

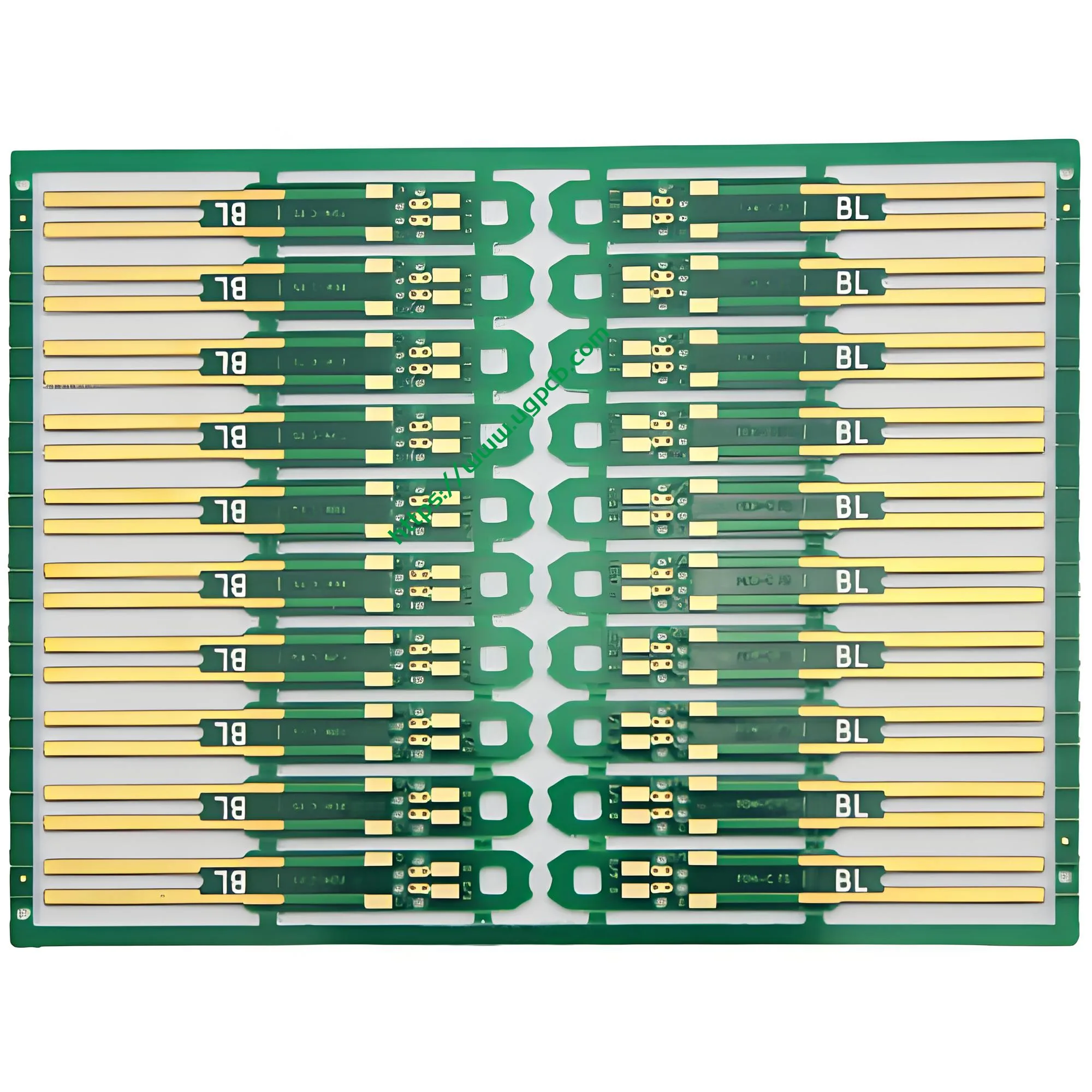

이미지 제안 2: Microscope image comparing precise 12mil trace/space edges.

-

Image Alt Text: Close-up of high-precision 12mil trace/space on PCB, critical for consistent antenna impedance.

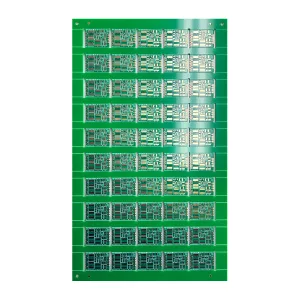

생산 과정 & 품질 보증

UGPCB’s production workflow strictly adheres to the special requirements for high-frequency PCB 제조:

Engineering Review → Halogen-Free Material Cutting → Laser Drilling → Deposition & Plating → Precision Pattern Transfer → Acid Etching (Strict Line Width Control) → ENIG Surface Finish → Solder Mask Application → Electrical & Flying Probe Testing → Final Inspection & 포장.

We implement enhanced controls, particularly during pattern transfer and etching, to achieve stringent trace tolerance requirements. Stability of the Dk value is verified through periodic sampling with network analyzers.

광범위한 응용 분야

This 2-layer halogen-free antenna PCB serves as the “heart” of numerous wireless communication devices. Typical applications include:

-

IoT 장치: Smart home sensors, Bluetooth modules, LoRa modules.

-

Network Communications: Wi-Fi 라우터, 무선 액세스 포인트, network cameras.

-

가전제품: Wireless headphones, remote controls, wearable technology.

-

산업 제어: Wireless data collectors, remote monitoring terminals.

Whether you require rapid 원기 PCB 제작 or large-scale volume production, UGPCB provides reliable, 효율적인 antenna PCB manufacturing and comprehensive PCBA 조립 서비스 to accelerate your product’s time-to-market.

-

이미지 제안 3: Collage of application scenarios (PCB integrated into end-products like smart home devices, 라우터, 웨어러블).

-

Image Alt Text: Application of 2-layer halogen-free antenna PCB in Wi-Fi routers, IoT sensors, and wireless devices.

Contact us today to get your customized 2-Layer Halogen-Free Antenna PCB solution and quote! Let UGPCB’s expertise become the solid foundation for your wireless product’s success.

UGPCB 로고

UGPCB 로고