UGPCB: How Precision-Driven Conventional PCB Design Powers Global Electronics Innovation

At a Shenzhen drone R&D center, Engineer Wang faced EMI test failures on the 7th flight controller PCB iteration – where minor RF interference caused system malfunction. After engaging UGPCB’s team, stack-up optimization şi grounding strategy reconstruction boosted signal integrity by 40%, accelerating product launch by two months. This real-world case demonstrates how professional PCB design dictates electronic product success.

Core Value and Technical Expertise in Conventional PCB Design

Conventional PCBs (2-16 straturi) remain the industry backbone, holding 75% global market share (Prismark 2023). Technical excellence manifests in three dimensions:

-

Signal Integrity Control

For frequencies >100MHZ, cel characteristic impedance formula Z₀ = 87/√(εᵣ+1.41) × ln(5.98H/(0.8W+T)) becomes critical. UGPCB engineers maintain ±7% impedance tolerance (exceeding IPC-6012B’s ±10% standard) through precise microstrip width (W), dielectric thickness (H), and copper weight (T) calculations. -

Thermal Management Engineering

Power device temperature rise follows ΔT = P × θⱼₐ (thermal resistance formula). Our 2oz copper + thermal via matrix designs reduce MOSFET junction temperature by 15-25°C, extending power module lifespan. -

EMC Compliance Design

Implementation of 3W Rule (Trace Spacing ≥ 3×Width) and mirror layer segmentation reduced medical device radiation by 12dB – exceeding EN 55032 Class B requirements.

Four Technical Pillars of UGPCB’s PCB Design Capabilities

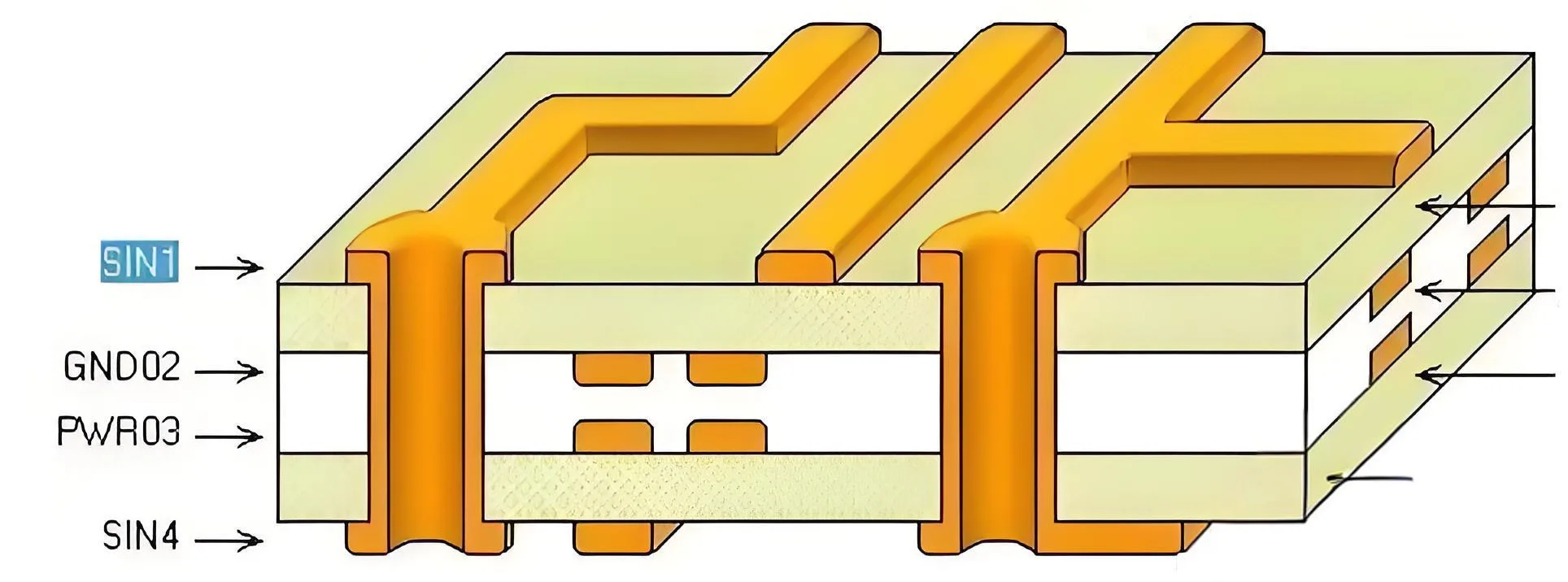

Precision Layer Stack-up Optimization

Our 4-layer industrial control solution:

L1 (Signal) - Prepreg - L2(GND Plane) - Core - L3(PWR Plane) - Prepreg - L4(Signal)

Uses Isola FR408HR (εᵣ=3.75, Tg=180°C) with 13-year material database experience, achieving loss tangent of 0.009 (@10GHz).

DFM-Oriented Intelligent Routing Principles

-

High-Speed Signals: Length matching tolerance ≤50mil

-

Power Routing: 20H Rule (power plane inset ≥20×dielectric thickness)

-

DFM Standards: 4/4mil trace/space, ≥8mil drills (compatible with 20 global PCBA manufacturers)

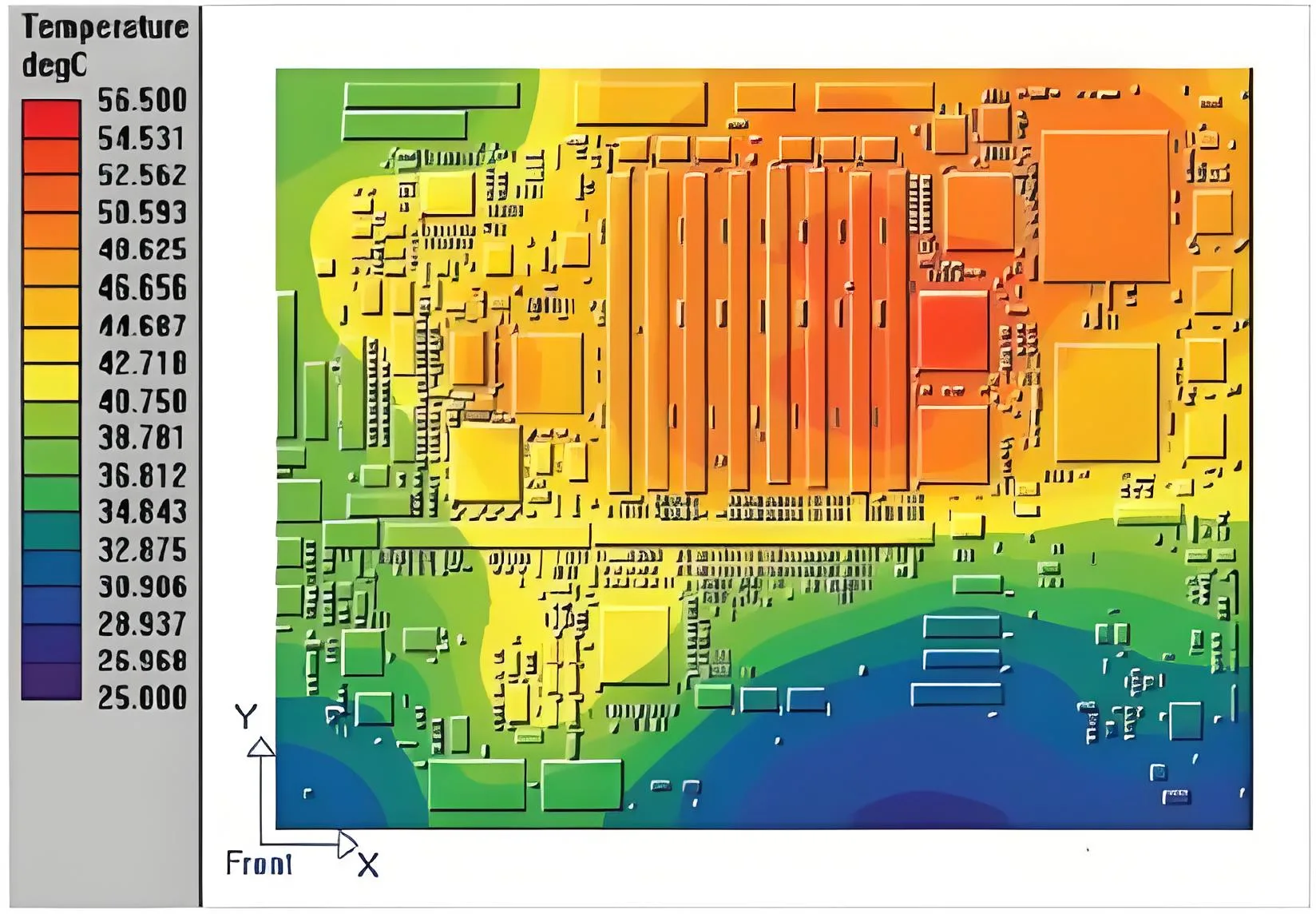

Thermal Engineering Solutions

Thermal analysis for 200W servo driver:

-

No cooling: IC junction temp 148°C (Critical)

-

With 4×24 thermal vias: 107° C.

-

With 2oz localized copper: 92° C. (Safe operating range)

End-to-End PCB Design Verification System

• Schematic DFA → 3D Assembly Verification → SI/PI Simulation → Thermal Stress Analysis → DFM Report

Client Success Stories: Technical Expertise Driving Business Value

Industrial IoT Gateway Design Breakthrough

-

Provocare: 6-layer board with 5xGbE + WiFi6 (EMI 23dB over limit)

-

Soluții:

✓ Pseudo-differential routing (spacing=2×width)

✓ Checkerboard power plane segmentation

✓ IC Faraday cage grounding -

Rezultat: FCC certification passed, 99.2% production yield

EV BMS Board Optimization

-

Parameters: 12-layer heavy-copper PCB, 300A continuous current

-

Inovații:

✓ 400μm embedded copper blocks

✓ 17% heatsink cost reduction through thermal simulation

✓ 22% size reduction with HDI microvias -

Impact: Secured 100,000-unit automotive order

Why Global Clients Choose UGPCB’s PCB Design Services

Technology Ecosystem Advantages

-

Data-Driven Design: Material database with <3% error (78 substrates, 256 foil combinations)

-

Collaborative Platform: Native Allegro/PADS/Altium file support

-

Knowledge Engine: 37 integrated standards (IPC-2221/2152 etc.)

Full-Cycle Service Efficiency

Quantifiable Client Benefits

-

Reducerea costurilor: 18% average board size reduction through DFM optimization

-

Efficiency: 92% first-pass success rate (37% above industry average)

-

Risk Mitigation: 85%+ EMI/SI issues resolved pre-production

Start Your High-Reliability PCB Design Journey

When a German automotive client faced CAN bus failures delaying production, UGPCB resolved issues in 48 hours through reference plane restructuring şi termination matching – proving our “Design-for-Manufacturing” philosophy where every 0.1mm trace optimization impacts market success.

Get Custom PCB Design Support Today:

① Schedule 1-on-1 Consultation with Senior Engineers

② Free Professional Technical Support

LOGO UGPCB

LOGO UGPCB

WeChat

Scanați codul QR cu WeChat