Introducere

Flexible Printed Circuit Boards (FPCs) have become indispensable in foldable smartphones, wearable devices, and aerospace electronics due to their ultra-thin profile and bendable nature. Cu toate acestea, their design complexity surpasses traditional rigid PCB -uri, requiring multidisciplinary expertise in materials science, mechanical simulation, and process innovation. This comprehensive guide explores critical aspects of flexible Design PCB through industry-proven methodologies and cutting-edge technologies.

1. Material Science: Foundation of Flexible PCBs

1.1 Substrate Selection: Balancing Performance and Cost

Flexible substrates must simultaneously achieve thermal stability (>260°C for PI vs <120°C for PET), bending endurance, and dielectric properties. Polyimide (Pi) dominates high-end applications with its low CTE (≈12 ppm/℃), while polyester (PET) serves cost-sensitive static applications. Emerging low-modulus PI substrates (<3 GPa) enable million-cycle dynamic bending durability.

Technical Formula:

Bending stress calculation:

σ = (E·t)/(2R)

Where E=elastic modulus, t=thickness, R=bend radius. Reducing E or increasing R decreases stress concentration by 62%.

1.2 Copper Foil and Coverlay: Mechanical Harmony

Rolled-annealed (RA) copper foil improves ductility by 30% over electrodeposited (ED) foil in dynamic bending zones. Optimal coverlay combines acrylic adhesive (15-25μm) with PI film for balanced adhesion and flexibility.

1.3 Protective Layer Innovations

Mesh ground planes and arc-shaped copper reinforcements (≥0.2mm width) reduce tearing risks by 70% in vulnerable areas like gold fingers. ENIG or OSP+selective gold plating ensures reliable soldering.

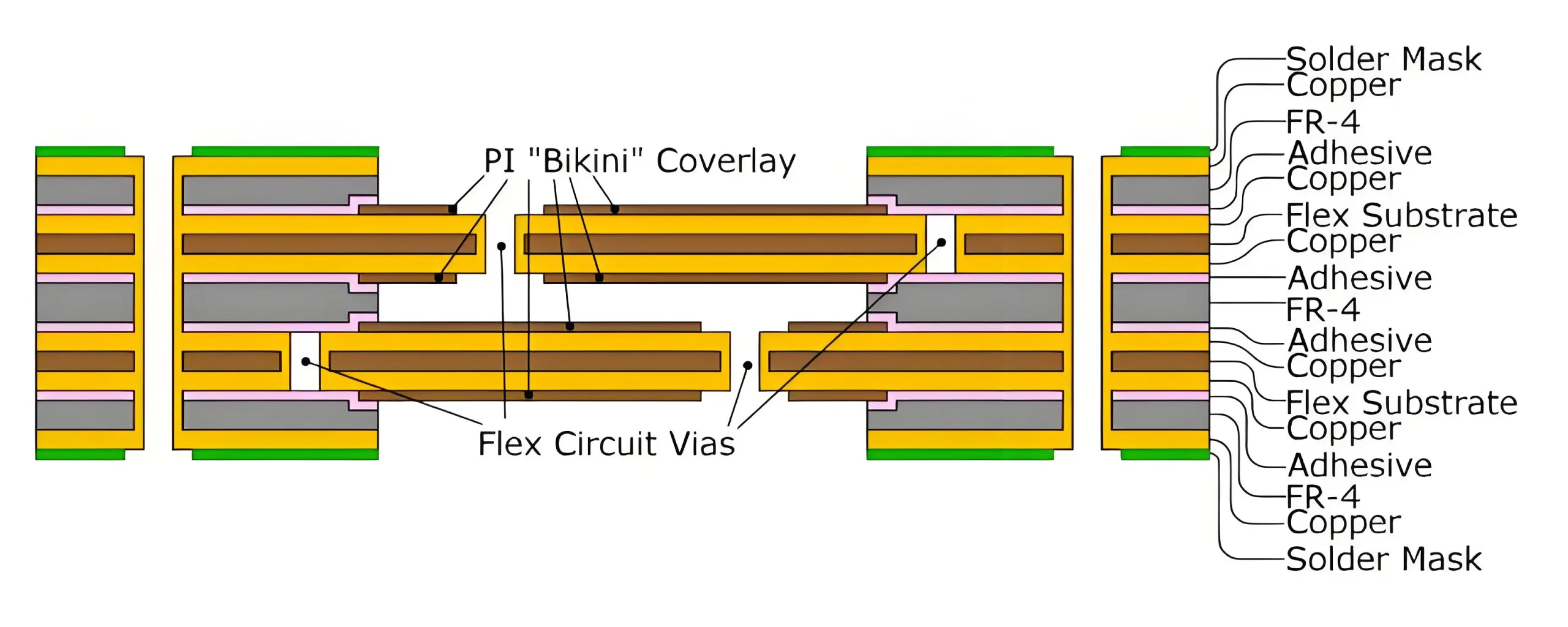

2. Stackup Architecture: Engineering Rigid-Flex Synergy

2.1 Layer Standardization and Signal Integrity

-

Signal layers: Central positioning minimizes EMI

-

Power planes: Solid copper (<50mΩ target impedance)

-

Ground layers: Grid patterns (≤5mm spacing) reduce loop areas

Studiu de caz: 8-layer rigid-flex PCB with 2R+4F+2R configuration achieves 100,000+ cicluri de îndoire.

2.2 Rigid-Flex Transition Zones

Implement 1mm+ buffer zones with perpendicular routing and arc corners (radius≥3×trace width) to distribute stress.

3. Dynamic Bending Optimization

3.1 Bend Radius Golden Rules

Minimum bend radius requirements:

-

Static: R<sub>min</sub> ≥5t

-

Dynamic: R<sub>min</sub> ≥10t

(De ex., 0.2mm PI requires ≥2mm dynamic radius)

3.2 Simulation-Driven Validation

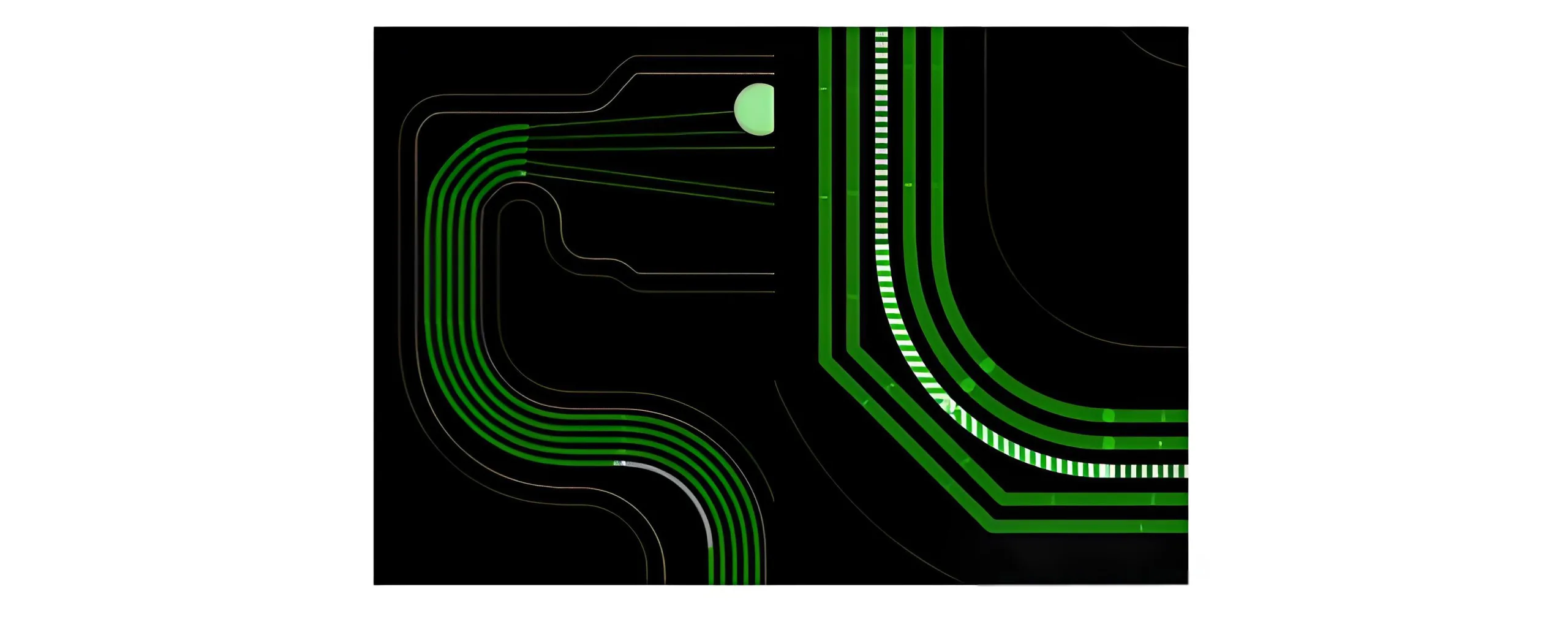

Finite Element Analysis (FEA) identifies high-strain areas. Serpentine routing in foldable phones improves fatigue life to 200,000+ cicluri.

4. Routing Principles: Electrical-Mechanical Balance

4.1 Bending Zone Prohibitions

-

No vias/components within 5mm of bend lines

-

Staggered adjacent-layer traces prevent “I-beam” stress

4.2 Controlul impedanței

Characteristic impedance formula for high-speed signals:

Z₀ = [87/√(e<sub>r</sub>+1.41)] × ln[5.98h/(0.8W+T.)]

Printre ei, er is the dielectric constant, h is the dielectric thickness, w is the line width, and t is the copper thickness.

Differential serpentine routing (2×spacing) minimizes crosstalk.

5. Manufacturing Collaboration

5.1 IPC-2581 Standard Implementation

Unified XML format reduces communication errors by 80%, boosting first-pass yield from 65% la 92% in drone antenna projects.

5.2 DFM Guidelines

-

Trace spacing: ≥4mil

-

Laser drilling: ≥4mil holes (±1mil accuracy)

-

Coverlay openings: 0.1mm larger than pads

6. Frontierele viitorului

6.1 3D Stretchable Circuits

UESTC’s 3D-LSC process enables meter-scale flex circuits with 5-layer stacking, applied in medical wearables.

6.2 Nanomaterial Breakthroughs

Graphene/PU composites achieve 10<sup>-6</sup> Ω·cm resistivity with <5% performance degradation after 100k bends.

Concluzie

Flexible PCB design demands cross-disciplinary innovation in materials, mechanics, and electronics. By implementing these strategies and adopting emerging standards like IPC-2581, engineers can develop next-generation flex circuits with enhanced reliability and density for advanced applications.

LOGO UGPCB

LOGO UGPCB