UGPCB 18-Layer Server PCB: Engineered for High-Performance Computing & Centros de datos

In the era of data centers and cloud computing, server stability and performance are critical to digital business operations. As the fundamental hardware carrier, the precision design and exceptional quality of Server PCB (Placas de circuito impreso) are paramount. Leveraging deep industry expertise and cutting-edge technology, UGPCB provides high-performance, highly reliable 18-layer server PCBs to meet the most demanding requirements of next-generation data center applications.

Descripción general del producto & Definición

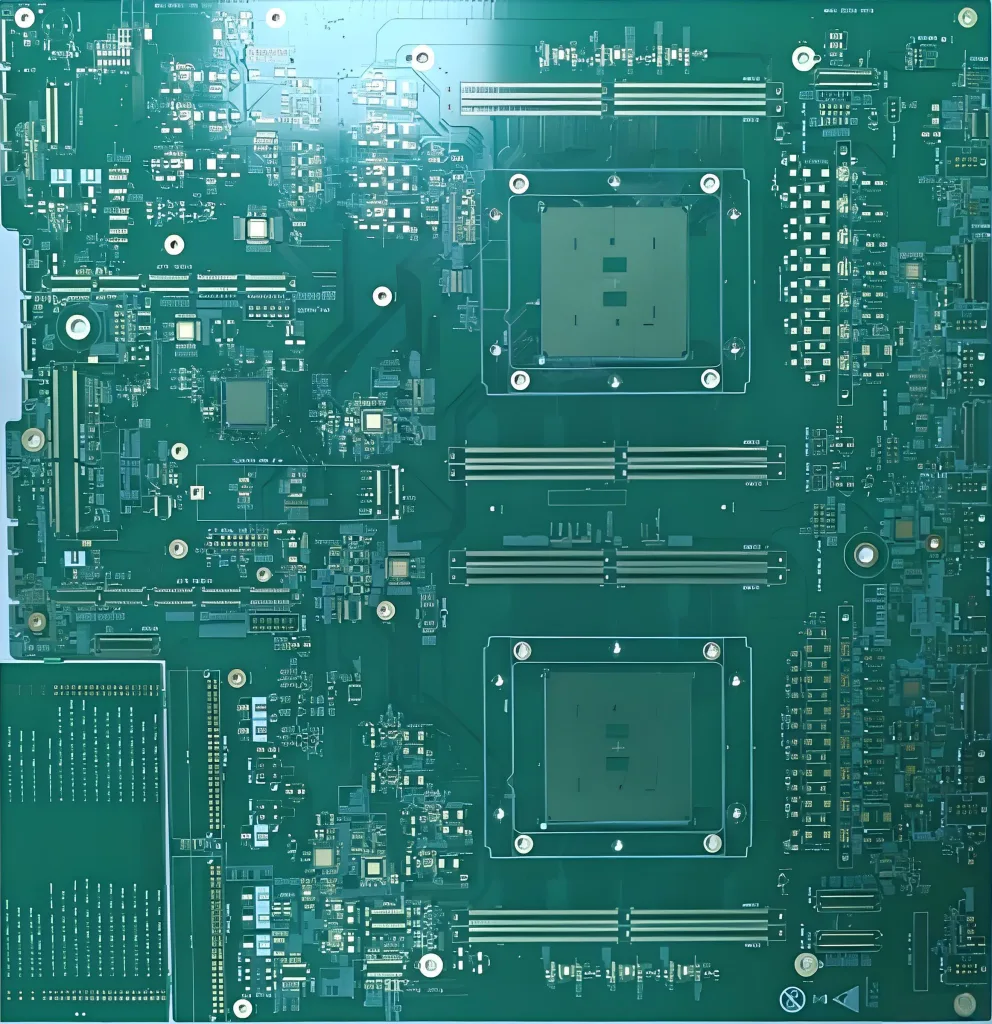

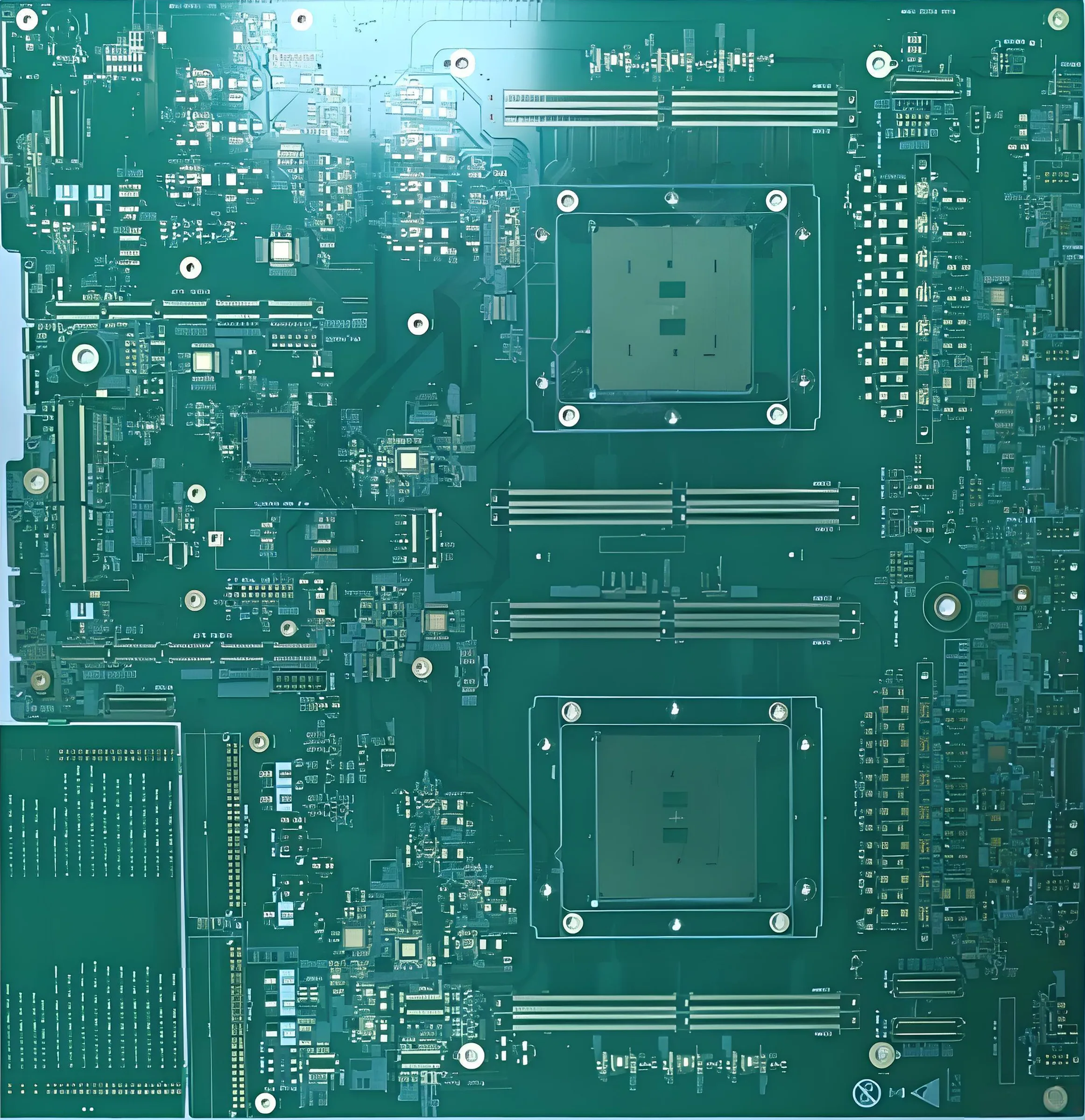

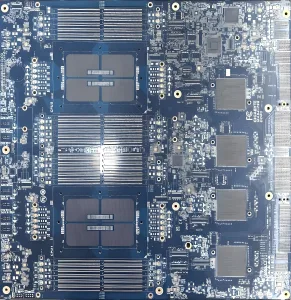

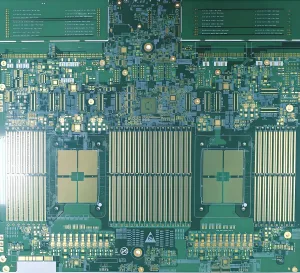

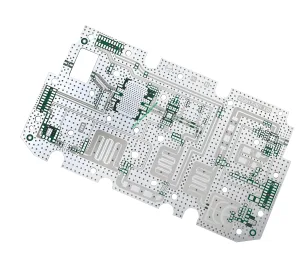

A server PCB is the core component of server motherboards, storage backplanes, and various functional daughter cards. It hosts critical components like CPUs, memoria, and chipsets, facilitating high-speed signal transmission, power distribution, and system interconnection. Designed specifically for high-performance application servers, this UGPCB product utilizes an 18-layer high multilayer structure and an enhanced board thickness of 2.4mm ±10%, serving as a robust hardware foundation for processing massive datasets and supporting high-speed computations.

Core Design Highlights & Technical Analysis

To address server platforms’ extreme demands for signal integrity, integridad del poder, y gestión térmica, this product integrates several key technologies:

-

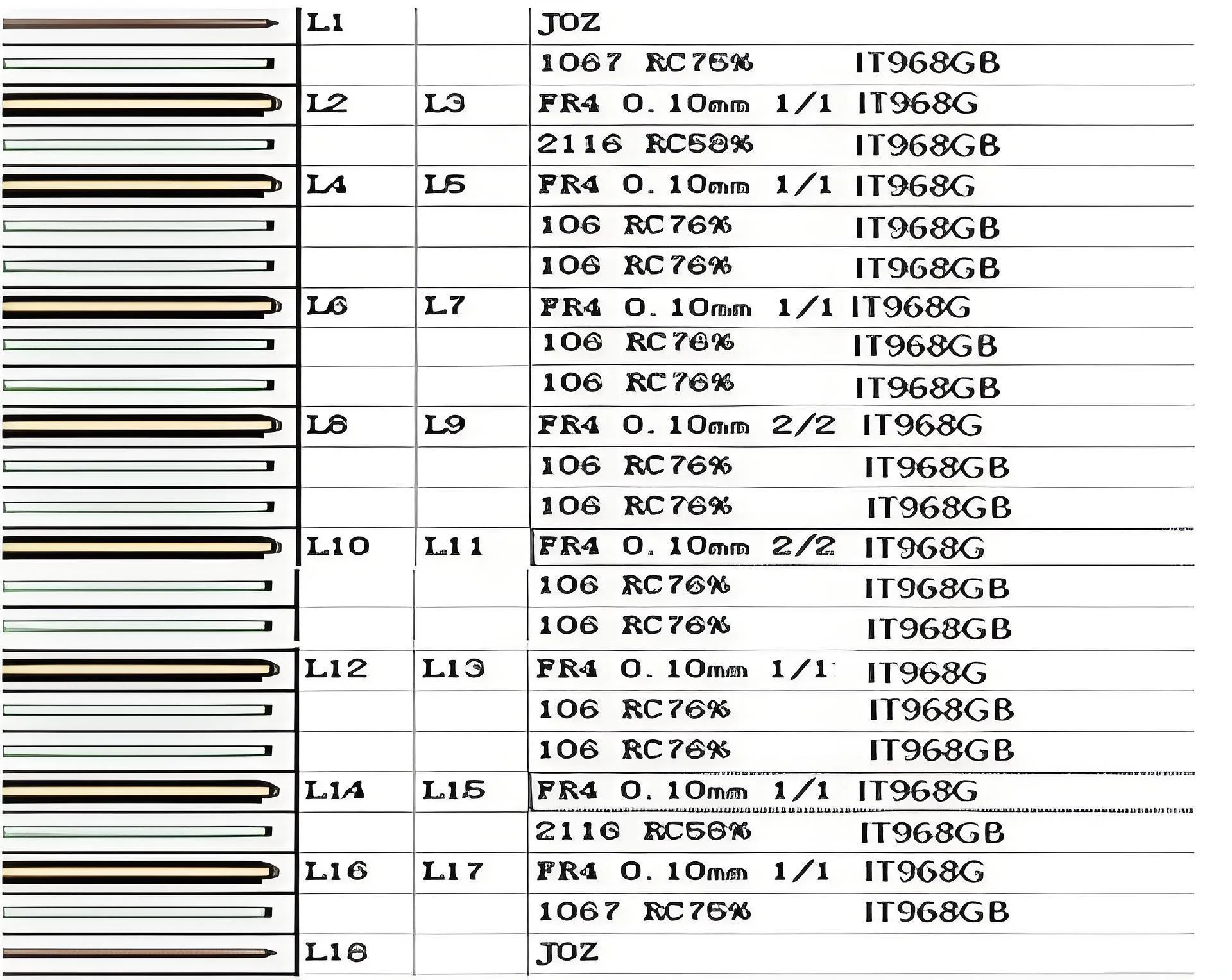

Advanced Stack-up & Materiales:

-

Laminado: Utilizes ITEQ IT968G high-speed, low-loss material. Its high Tg (Temperatura de transición vítrea) ensures dimensional stability and consistent electrical performance under prolonged high-temperature server operation, effectively reducing signal transmission loss.

-

capas & Peso del cobre: An 18-layer complex stack-up with a meticulously designed hybrid copper weight scheme (featuring 2Oz thick copper foil on select inner layers). This optimizes the current-carrying capacity and thermal performance of power planes while enabling fine-line routing on high-speed signal layers.

-

-

Precision Routing & Interconnection:

-

Line Capability: Achieves ultra-fine line width/space of 0.1mm/0.1mm, meeting the fan-out and interconnection requirements for high-density BGA packages (p.ej., UPC, GPU, FPGA).

-

Tecnología de microvia: Supports a minimum mechanical drill diameter of 0.20mm, enhancing routing density and space utilization.

-

-

Key Technologies for Signal Integrity:

-

Back-Drilling: For high-speed differential signals (p.ej., Pítico, SAS, Éternet), the back-drilling process removes unused copper stubs from through-holes, significantly reducing signal reflection and attenuation. This is a core process for ensuring signal quality in PCB de alta velocidad.

-

RTF Copper Foil: Uses Reverse Treated Foil, which provides a smoother copper surface. This effectively reduces skin effect loss for high-frequency signals, improving signal transmission efficiency.

-

-

Reliable Surface Finish:

-

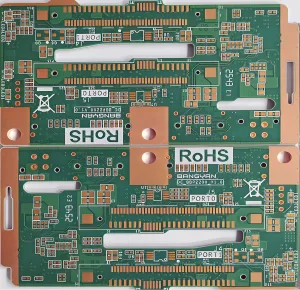

Oro de inmersión de níquel químico (ACEPTAR) is applied as the final surface treatment. ENIG provides a flat surface, excellent solderability, a reliable contact interface, and long-term oxidation resistance, making it ideal for soldering dense, fine-pitch componentes on server PCBs.

-

Características del producto & Ventajas

-

Exceptional Electrical Performance: High-speed IT968G laminate combined with back-drilling and RTF foil ensures low-loss, low-latency transmission of high-frequency signals, making it an ideal choice for PCB de alta frecuencia y PCB de alta velocidad.

-

Superior Power Handling & Gestión Térmica: 2Oz inner-layer copper and the 2.4mm board design enhance current-carrying capacity, overall structural rigidity, and thermal conductivity.

-

Densidad alta & Fiabilidad: The 18-layer routing space coupled with 0.1/0.1mm line width/space supports the most complex designs. Strict process control and high-Tg materials ensure long-term reliability for 24/7 uninterrupted operation.

-

End-to-End Service Support: UGPCB offers not only top-tier fabricación de PCB but also a one-stop solution from design review to production, accelerating your time-to-market.

Production Process Overview

Our manufacturing adheres to stringent Normas IPC and a quality management system:

Engineering Review → Material Preparation → Inner Layer Imaging → Lamination → Drilling & Back-Drilling → Hole Metallization → Outer Layer Imaging → Plating (for hybrid copper weight) → Solder Mask Application (Pre-ENIG) → ENIG → Routing / Profiling → Electrical Test & Inspección final

https://via.placeholder.com/800×450.png?text=18-Layer+PCB+Cross-Section

Alt Text: Cross-sectional view of an 18-layer server PCB board, detailing precise lamination and back-drilled via structures for high-speed signal transmission.

Aplicaciones & Clasificación

This high-performance PCB is widely used in:

-

Enterprise & Cloud Server Motherboards

-

Data Center AI Computing Acceleration Cards

-

High-Performance Storage Servers & Backplanes

-

Network Switch & Communication Equipment Core Boards

Clasificación Técnica:

-

Por recuento de capas: Alto PCB multicapa (18 capas)

-

Por tecnología: High-Speed/High-Frequency PCB, Back-Drilled PCB, PCB de cobre pesado

-

Por aplicación: Server/Data Center PCB

-

By Surface Finish: ACEPTAR (Oro de inmersión de níquel químico) tarjeta de circuito impreso

Elija UGPCB, and you select more than just a high-quality server PCB board; you gain a trusted partner in advanced PCB manufacturing. We are dedicated to translating complex technical details into reliable advantages for your products, empowering your next-generation data center solutions.

Contact our expert team today for a customized PCB solution quote and technical consultation!

UGPCB LOGO

UGPCB LOGO