Introducción a la PCB del módulo de fibra óptica

Descripción general y definición

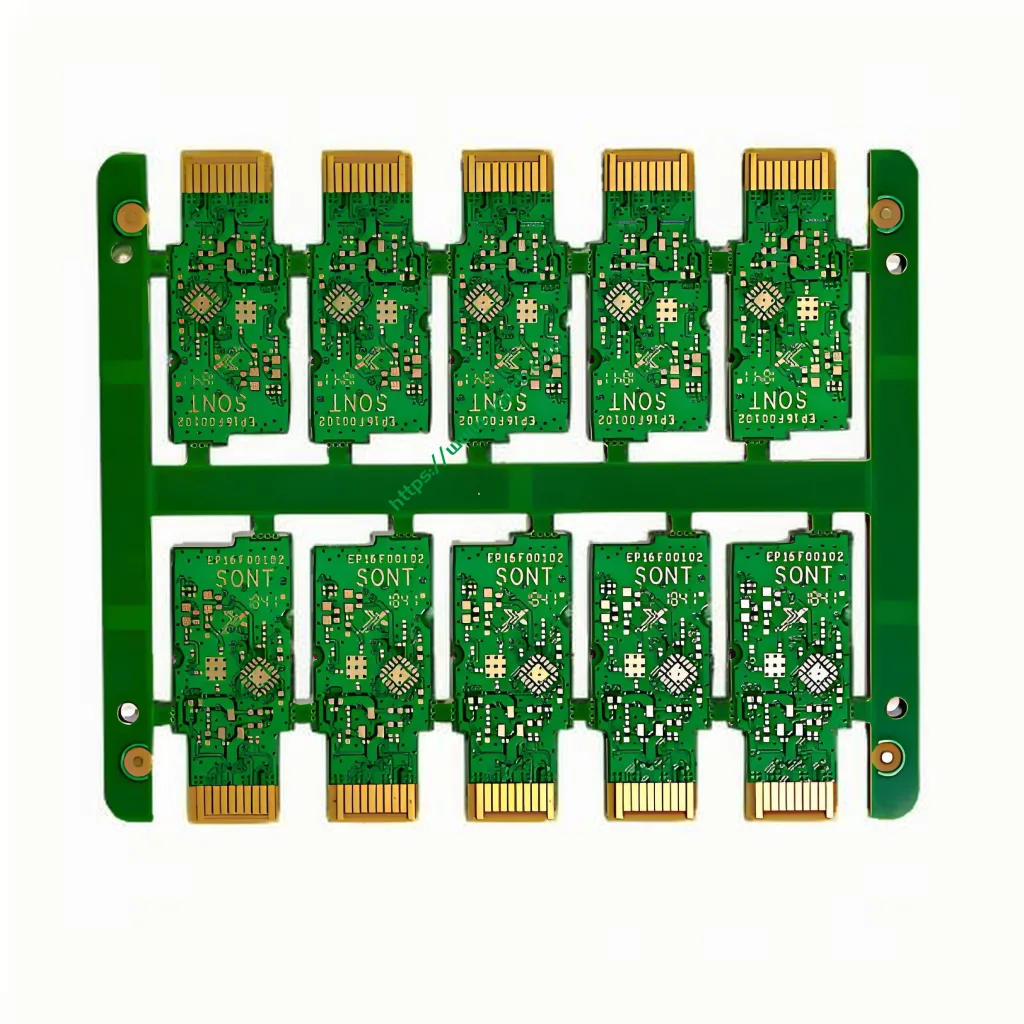

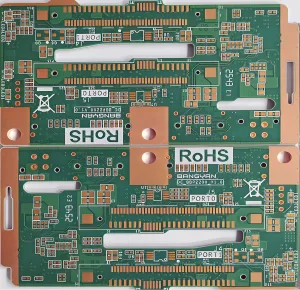

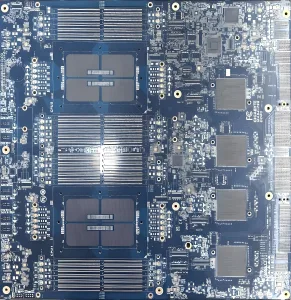

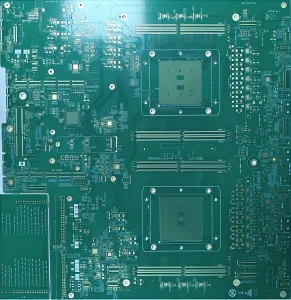

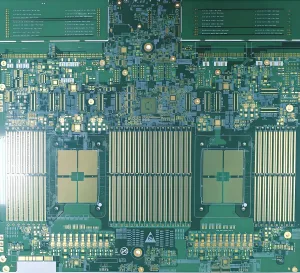

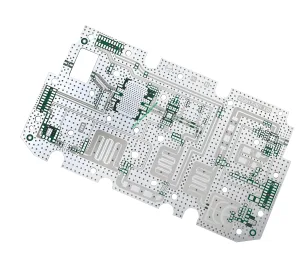

PCB para módulos de fibra óptica, También conocido como tableros de fibra óptica., estan especializados placas de circuito impreso (PCB) Diseñado para su uso en sistemas de comunicación de fibra óptica.. Estos PCB Son componentes integrales en las redes modernas de telecomunicaciones y transmisión de datos debido a su capacidad para manejar transferencias de datos de alta velocidad con una mínima pérdida de señal..

Propósito y aplicación

El objetivo principal de una PCB de módulo de fibra óptica es proporcionar una plataforma confiable para montar e interconectar componentes ópticos como láseres., fotodetectores, y otros dispositivos optoelectrónicos. Estos PCB se utilizan comúnmente en:

- Equipos de telecomunicaciones

- Centros de datos

- Dispositivos de red de alta velocidad

- Equipo de imágenes médicas

- Sistemas de automatización industrial

Clasificación

Los PCB de módulos de fibra óptica se pueden clasificar según varios criterios, incluidos:

- Número de capas (p.ej., monocapa, de dos caras, multicapa)

- Composición de materiales (p.ej., TRONOME 6, Panasonic M6)

- control de impedancia (p.ej., 50 ohmios, 100 ohmios)

- Tratamiento superficial (p.ej., oro de inmersión, dedos de oro)

Material y construcción

Material

El PCB del módulo de fibra óptica utiliza MEGTRON 6, también conocido como Panasonic M6, que es un material de alto rendimiento que ofrece una excelente estabilidad térmica y resistencia mecánica.. Esto lo hace ideal para aplicaciones que requieren durabilidad y confiabilidad..

Detalles de construcción

- capas: El PCB consiste en 8 capas, proporcionando un amplio espacio para diseños de circuitos complejos y colocación de componentes.

- Color: Disponible en verde y blanco, permitiendo una fácil diferenciación e identificación en diversas aplicaciones.

- Espesor terminado: La PCB tiene un espesor final de 1,0 mm., optimizando tanto la integridad estructural como la eficiencia del espacio.

- Espesor de cobre: Con un espesor de cobre de 1OZ (onza), La PCB garantiza una conductividad eléctrica eficiente.

Características de rendimiento

- Control de impedancia: La PCB mantiene valores de impedancia de 100 ± 7% y 50 ± 10%, Garantizar una calidad de transmisión de señal constante..

- Velocidad: Capaz de manejar velocidades de hasta 400 g., haciéndolo adecuado para aplicaciones de alta frecuencia.

- Tolerancia: La tolerancia entre el dedo dorado y el borde de la placa es de ±0,05 mm., asegurando una alineación precisa y confiabilidad de la conexión.

Proceso de producción

El proceso de fabricación de una PCB de módulo de fibra óptica implica múltiples etapas que incluyen:

- Preparación de material: Seleccionar y preparar el material base. (TRONOME 6).

- Apilamiento de capas: Apilar varias capas del material de placa de circuito impreso para lograr el espesor y funcionalidad deseados.

- Grabado de patrones: Usar grabado químico o corte por láser para crear los patrones de circuito en cada capa..

- Laminación: Comprimir las capas juntas bajo alta presión y temperatura para formar una unidad cohesiva.

- Enchapado: Aplicar revestimiento de cobre a la superficie de la PCB para garantizar una buena conectividad eléctrica.

- Tratamiento superficial: Tratar la superficie con oro de inmersión y agregar dedos de oro para mejorar la conductividad y la resistencia a la corrosión..

- Control de calidad: Realizar pruebas rigurosas para garantizar que la PCB cumpla con todas las especificaciones de rendimiento.

Características clave y ventajas

- Alta integridad de la señal: Mantiene la pureza de la señal a largas distancias, crucial para las comunicaciones por fibra óptica.

- Durabilidad: Fabricado con materiales robustos que soportan condiciones ambientales adversas..

- Precisión: La alta precisión en la fabricación garantiza conexiones confiables y una pérdida mínima de señal..

- Versatilidad: Adecuado para una amplia gama de aplicaciones debido a su diseño adaptable y propiedades del material..

Escenarios de uso

Los PCB de módulos de fibra óptica son esenciales en escenarios donde la transmisión de datos a alta velocidad es crítica, como:

- Redes de Telecomunicaciones: Garantizar un flujo de datos fluido a través de grandes distancias.

- Centros de datos: Apoyar la columna vertebral de las operaciones de almacenamiento y recuperación de datos..

- Equipo médico: Mejora del rendimiento de los dispositivos de diagnóstico e imágenes..

- Aplicaciones industriales: Facilitando sistemas de automatización y control con alta precisión y confiabilidad..

En conclusión, El PCB del módulo de fibra óptica representa un pináculo del avance tecnológico en el ámbito de la comunicación de datos de alta velocidad.. Su cuidado diseño, materiales superiores, y los estrictos procesos de fabricación contribuyen colectivamente a su rendimiento y confiabilidad incomparables., convirtiéndolo en un componente indispensable en las infraestructuras modernas de centros de datos y telecomunicaciones. Ya sea permitiendo conexiones a Internet ultrarrápidas o garantizando la precisión de las imágenes médicas, Esta PCB es un testimonio del ingenio humano a la hora de aprovechar el poder de la luz para la transferencia de información..

UGPCB LOGO

UGPCB LOGO