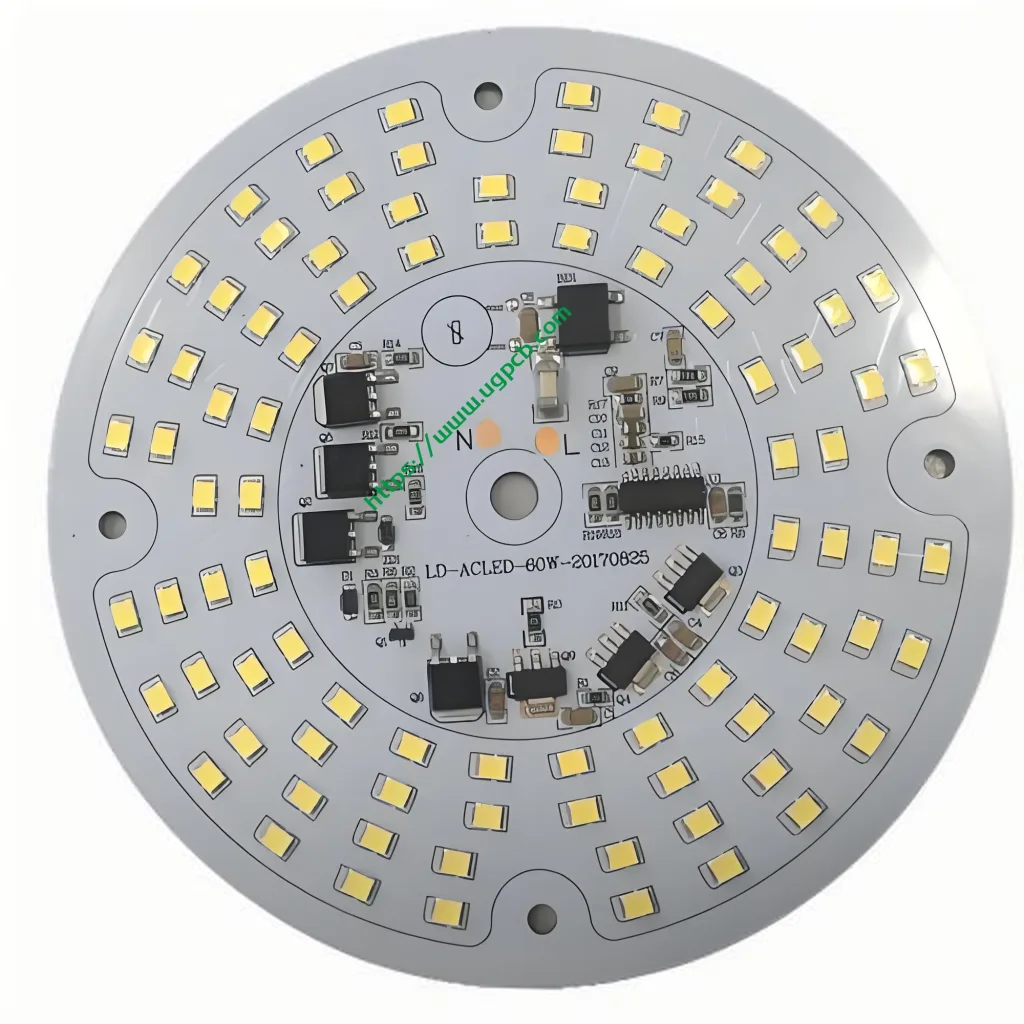

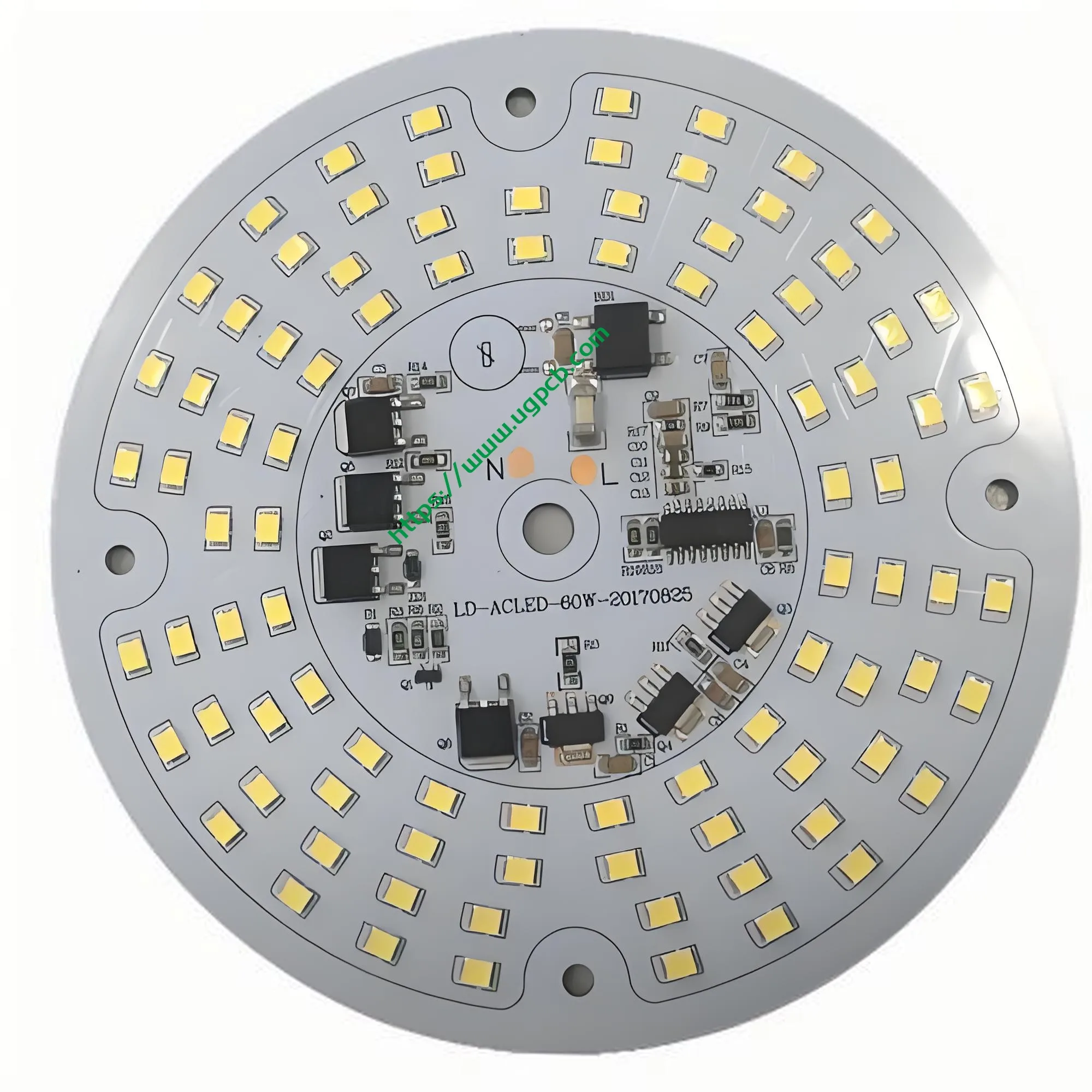

Light LED PCBA Overview

Introducción

The Light LED PCBA is a compact and efficient printed circuit board assembly designed for LED lighting applications. This PCBA features 1-2 layers of conductive material, making it suitable for simpler circuit designs while maintaining high performance and reliability.

Definición

A Light LED PCBA refers to a printed circuit board assembly that incorporates surface mount technology (SMT) or through-hole technology (Tht) components specifically for LED lighting applications. The PCBA includes all necessary electronic components soldered onto the PCB, ready for integration into an LED lighting system.

Principio de trabajo

The working principle of a Light LED PCBA involves using conductive copper traces on a non-conductive substrate to create electrical pathways. These pathways connect various electronic components such as LEDs, resistencias, and capacitors. When electrical current flows through these pathways, it powers the LEDs, causing them to emit light.

Aplicaciones

This type of PCBA is widely used in various LED lighting applications, incluido:

- Residential and commercial lighting fixtures

- Automotive lighting systems

- Signage and display lighting

- Decorative and architectural lighting

Clasificación

Los PCBA se pueden clasificar en función de varios criterios:

- Por número de capas: Single-layer, doble capa, or multi-layer (incluido 1-2 capas)

- Por tipo de componentes: Agujero, montaje en superficie, o una combinación de ambos

- By substrate material: FR-4, aluminio, cobre, etc..

Materiales

The primary materials used in the construction of a Light LED PCBA include:

- sustrato: FR-4, aluminio, cobre

- Tratamiento superficial: HASL sin plomo / OSP (Organic Solvent Protection)

- Solder Resist: Blanco

- Espesor de cobre: 0.5oz-2oz

- Color de serigrafía: Negro

Actuación

El rendimiento de este PCBA se caracteriza por:

- Alta conductividad térmica debido a las capas de cobre

- Baja pérdida de señal e integridad de alta señal

- Resistance to environmental factors such as humidity and temperature variations

- Cumplimiento de ROHS y estándares de ensamblaje sin plomo

Estructura

The structure of a Light LED PCBA typically includes:

- Conductive copper traces on a non-conductive substrate

- Surface mount and/or through-hole components soldered onto the PCB

- A white solder mask covering the top layer for protection and identification

- A black silk screen for labeling and component identification

Características

Las características clave de este PCBA incluyen:

- Compact and lightweight design suitable for space-constrained applications

- Capacidades de gestión térmica superiores

- Enhanced durability and longevity in various lighting environments

- Compatibility with a wide range of LED components

Proceso de producción

The production process of a Light LED PCBA involves several steps:

- Diseño: Uso de un software especializado para crear el diseño del circuito y la colocación de componentes.

- Preparación de material: Selecting and preparing the substrate, lámina de cobre, y otros materiales.

- Apilamiento de capas: Apilamiento de las capas de cobre y materiales dieléctricos.

- Mediante perforación: Perforación de agujeros a través de las capas apiladas para vias (if applicable).

- Enchapado: Colocar los vías con cobre para garantizar la conectividad eléctrica.

- Aguafuerte: Eliminar exceso de cobre para formar el patrón de circuito deseado.

- Colocación de componentes: Soldering surface mount and/or through-hole components onto the PCB.

- Pruebas: Realizar pruebas rigurosas para garantizar la funcionalidad y el cumplimiento de los estándares.

- Inspección final: Asegurar que la PCBA cumpla con todos los criterios de calidad y rendimiento.

Casos de uso

Common use cases for the Light LED PCBA include:

- Residential and commercial lighting fixtures where energy efficiency and longevity are crucial

- Automotive lighting systems requiring high reliability and performance

- Signage and display lighting in retail and advertising applications

- Decorative and architectural lighting projects needing custom designs and high aesthetics

Conclusión

The Light LED PCBA is an advanced and reliable solution for various LED lighting applications. Its compact design, materiales de alto rendimiento, and compliance with industry standards make it an ideal choice for engineers and manufacturers seeking efficient and durable electronic solutions.

UGPCB LOGO

UGPCB LOGO