Introduction

Cartes de circuits imprimés flexibles (FPC) sont devenus indispensables dans les smartphones pliables, appareils portables, et l'électronique aérospatiale en raison de leur profil ultra-mince et de leur nature pliable. Cependant, leur complexité de conception surpasse les rigides traditionnels PCB, nécessitant une expertise multidisciplinaire en science des matériaux, simulation mécanique, et innovation de processus. Ce guide complet explore les aspects critiques de la flexibilité Conception de circuits imprimés grâce à des méthodologies éprouvées et des technologies de pointe.

1. Science des matériaux: Fondation de PCB flexibles

1.1 Sélection du substrat: Équilibrer les performances et les coûts

Les substrats flexibles doivent simultanément atteindre une stabilité thermique (>260°C pour le PI vs <120°C pour le PET), endurance à la flexion, et propriétés diélectriques. Polyimide (PI) domine les applications haut de gamme avec son faible CTE (≈12 ppm/℃), tandis que le polyester (ANIMAL DE COMPAGNIE) sert des applications statiques sensibles aux coûts. Substrats PI émergents à faible module (<3 GPa) permettre une durabilité en flexion dynamique d'un million de cycles.

Formule technique:

Calcul de la contrainte de flexion:

S = (Et)/(2R.)

Où E = module élastique, t=épaisseur, R = rayon de courbure. Réduire E ou augmenter R diminue la concentration de stress de 62%.

1.2 Feuille de cuivre et revêtement: Harmonie mécanique

Recuit laminé (Rampe) la feuille de cuivre améliore la ductilité en 30% sur-électrodéposé (Élégant) film dans des zones de flexion dynamiques. La couverture optimale combine un adhésif acrylique (15-25µm) avec film PI pour une adhérence et une flexibilité équilibrées.

1.3 Innovations en matière de couche de protection

Plans de masse en maille et renforts en cuivre en forme d'arc (largeur ≥0,2 mm) réduire les risques de déchirure en 70% dans les zones vulnérables comme les doigts d'or. Le placage à l'or sélectif ENIG ou OSP+ garantit une soudure fiable.

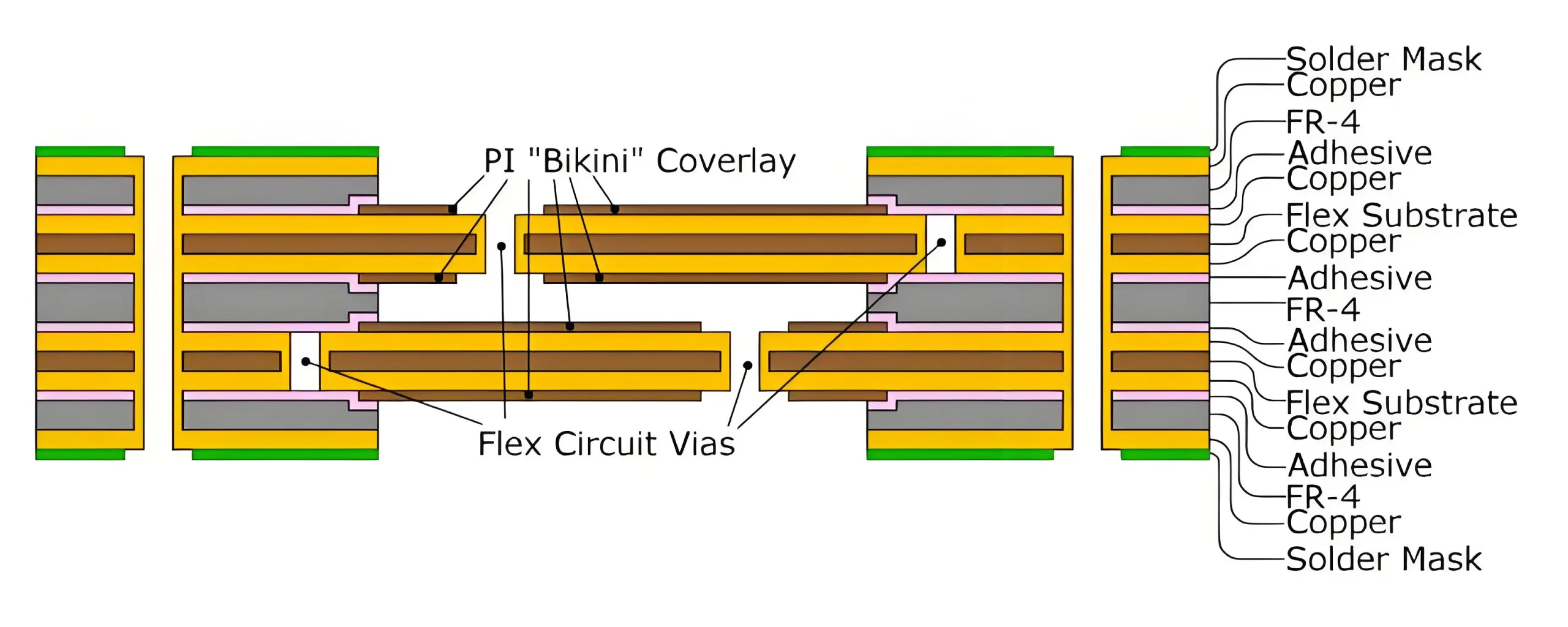

2. Architecture d'empilement: Synergie d'ingénierie rigide-flexible

2.1 Standardisation des couches et intégrité du signal

-

Couches de signalisation: Le positionnement central minimise les EMI

-

Avions à moteur: Cuivre massif (Impédance cible <50mΩ)

-

Couches de sol: Modèles de grille (Espacement ≤5 mm) réduire les zones de boucle

Étude de cas: 8-Le PCB rigide-flexible avec configuration 2R+4F+2R permet d'obtenir 100,000+ cycles de pliage.

2.2 Zones de transition rigides

Implémentez des zones tampons de plus de 1 mm avec un routage perpendiculaire et des coins en arc. (rayon≥3×largeur de trace) répartir le stress.

3. Optimisation du pliage dynamique

3.1 Règles d'or du rayon de courbure

Exigences minimales en matière de rayon de courbure:

-

Statique: R.<sous>min</sous> ≥5 tonnes

-

Dynamique: R.<sous>min</sous> ≥10 tonnes

(par ex., 0.2mm PI nécessite un rayon dynamique ≥2 mm)

3.2 Validation basée sur la simulation

Analyse par éléments finis (Fea) identifie les zones à forte contrainte. Le routage serpentin dans les téléphones pliables améliore la durée de vie en fatigue 200,000+ cycles.

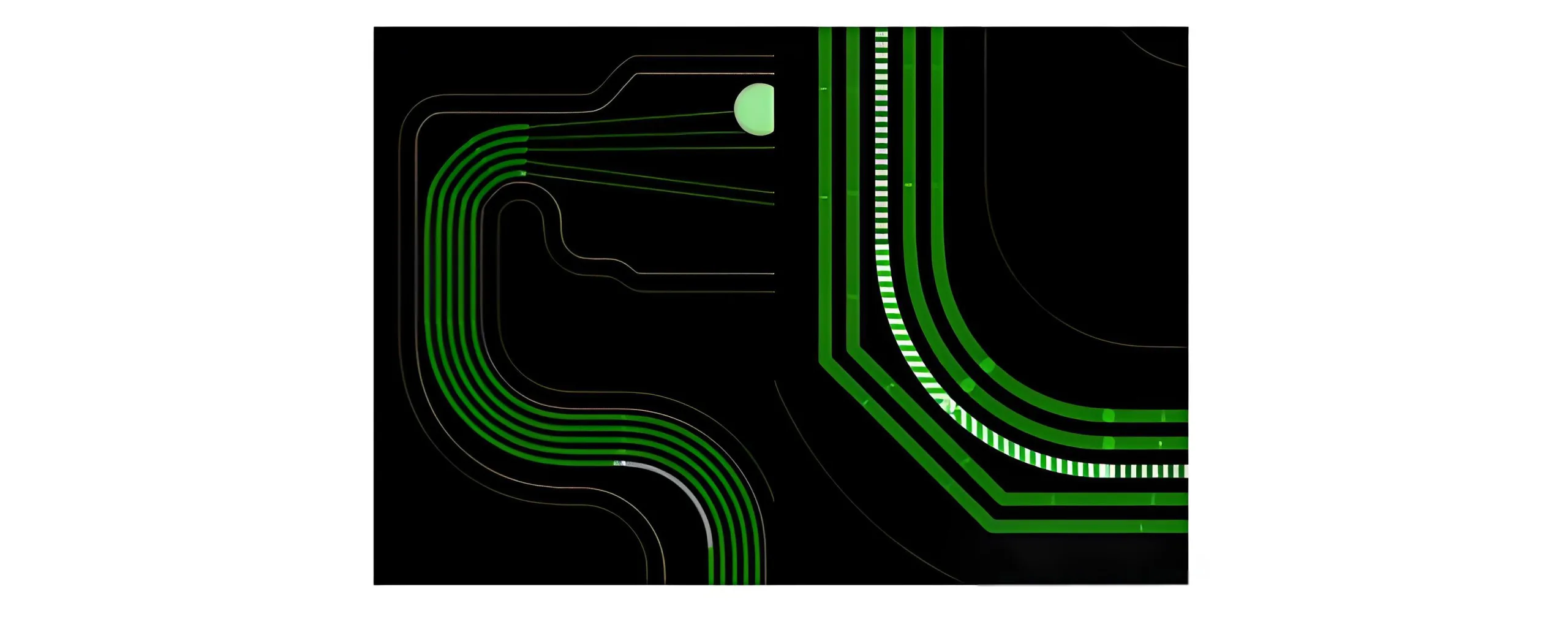

4. Principes de routage: Équilibre électrique-mécanique

4.1 Interdictions des zones de pliage

-

Aucun via/composant à moins de 5 mm des lignes de pliage

-

Les traces décalées des couches adjacentes empêchent “poutre en I” stresser

4.2 Contrôle de l'impédance

Formule d'impédance caractéristique pour les signaux à grande vitesse:

Z₀ = [87/√(e<sous>r</sous>+1.41)] × LN[5.98h /(0.8W + T)]

Parmi eux, er est la constante diélectrique, h est l'épaisseur du diélectrique, w est la largeur de la ligne, et t est l'épaisseur du cuivre.

Acheminement différentiel en serpentin (2×espacement) minimise la diaphonie.

5. Collaboration en matière de fabrication

5.1 Implémentation de la norme IPC-2581

Le format XML unifié réduit les erreurs de communication en 80%, augmentant le rendement du premier passage de 65% à 92% dans les projets d'antennes de drones.

5.2 Lignes directrices du DFM

-

Espacement des traces: ≥4 millions

-

Forage laser: Trous ≥4mil (Précision de ± 1 mil)

-

Ouvertures de couverture: 0.1mm plus grand que les coussinets

6. Futures frontières

6.1 3D Circuits extensibles

Le processus 3D-LSC de l'UESTC permet des circuits flexibles à l'échelle métrique avec un empilement à 5 couches, appliqué dans les wearables médicaux.

6.2 Percées en matière de nanomatériaux

Les composites graphène/PU atteignent 10<souper>-6</souper> Résistivité Ω·cm avec une dégradation des performances de <5 % après 100 000 courbures.

Conclusion

Conception de circuits imprimés flexible exige une innovation interdisciplinaire dans les matériaux, mécanique, et électronique. En mettant en œuvre ces stratégies et en adoptant des normes émergentes comme IPC-2581, les ingénieurs peuvent développer des circuits flexibles de nouvelle génération avec une fiabilité et une densité améliorées pour des applications avancées.

LOGO UGPCB

LOGO UGPCB